Dropshipping automation software has transformed how modern e-commerce entrepreneurs scale their businesses without managing physical inventory. If you’re running a dropshipping business, you already know that manual order processing, inventory tracking, and supplier communication drain your time and resources. That’s where automated solutions come in. This comprehensive guide walks you through everything you need to know about dropshipping automation software—from how it works to which platforms deliver real results.

Let me be straight with you: most successful dropshippers aren’t grinding away manually syncing orders anymore.They’ve moved to automation, and the numbers prove it works. Industry data shows that dropshippers using automated software cut operational costs by 40-60% while simultaneously processing orders 3-5x faster than their manual counterparts.

Here’s the reality I’ve witnessed across thousands of sellers: whether you’re a complete beginner just starting out or an experienced seller looking to scale, the right dropshipping automation software becomes your competitive edge.It’s not just about working smarter—it’s about building a business model that actually generates passive income instead of consuming your life.

In this guide, I’ll break down exactly what dropshipping automation software is, how it streamlines your entire operation from product sourcing to fulfillment, and whether it actually makes sense for your specific situation. We’ll explore the tangible benefits, real costs involved, honest ROI expectations, and my recommendations for platforms that actually deliver. By the end, you’ll have a clear action plan for implementing automation in your dropshipping business.

What Is Dropshipping Automation Software?

How Dropshipping Automation Software Streamlines Your Global E-Commerce Operations

When I first started in cross-border e-commerce, I watched sellers spend entire nights manually processing orders, updating inventory across multiple platforms, and coordinating with suppliers via email chains that never seemed to end. It was chaotic, error-prone, and honestly, a complete waste of human potential.

That’s when I realized the real game-changer wasn’t just finding better suppliers or cheaper products—it was automating the repetitive, soul-crushing tasks that consumed 70% of operational time. Over the years building ASG, I’ve seen firsthand how dropshipping automation software transforms a struggling operation into a well-oiled machine. It’s not magic. It’s systematic efficiency.

In this section, I’ll break down exactly what dropshipping automation software is, why it matters for your bottom line, and how to separate the hype from reality. Whether you’re just testing your first product or scaling to thousands of daily orders, this foundation will help you make smarter technology decisions.

What Exactly Is Dropshipping Automation Software?

Dropshipping automation software is a suite of integrated tools designed to eliminate manual work across your entire order-to-delivery pipeline. Think of it as the nervous system connecting your online store, your suppliers’ warehouses, and your logistics network into one synchronized ecosystem.

The core function? Automatically capturing orders from your storefront, syncing inventory in real-time, generating purchase orders to suppliers, and tracking shipments—all without you clicking a single button after the initial setup.

According to Shopify’s definitive guide on dropshipping, the integration of automation tools has become essential for sellers managing multiple sales channels simultaneously. I’ve personally worked with clients running operations across Shopify, Amazon, and eBay simultaneously, and without automation, the order reconciliation alone would require a dedicated full-time employee.

The Core Working Principles Behind the Scenes

Here’s how the machinery actually works. When a customer places an order on your Shopify store, the automation software captures that transaction data instantly. Your ERP (Enterprise Resource Planning) system immediately checks inventory across all your warehouses. If stock exists, the system auto-generates a purchase order to your supplier with all customer specifications.

The supplier’s system receives the order, picks and packs the item, and transmits tracking information back through your dropshipping automation software. Your customer receives an automated notification with their tracking number. Meanwhile, your inventory dashboard updates in real-time across all sales channels—preventing the nightmare scenario where you sell the same item twice.

This entire cycle can happen in under 48 hours. I’ve seen teams that previously required 3-4 days to process orders cut that down to 1-3 days using proper automation infrastructure. That’s not incremental improvement—that’s competitive advantage.

Why This Technology Matters More Than Ever

The global e-commerce market is experiencing explosive growth. Statista reports that worldwide online marketplace revenues exceeded $2 trillion in 2023, and automation has become the differentiator between sellers who scale and those who get stuck at a ceiling.

Consider the economics: a manual order processing operation requires multiple team members working shifts. Each person costs between $15-25 per hour in most markets. A basic dropshipping automation software typically costs $50-300 monthly. The math is brutal for manual operations. But beyond cost, there’s speed—your ability to fulfill orders faster than competitors directly impacts customer satisfaction and repeat purchase rates.

In my experience building ASG’s fulfillment operations, I’ve observed that sellers using proper automation software maintain 95%+ on-time delivery rates, while those still relying on manual processes average 78-82%. That gap translates directly to customer lifetime value and marketplace ratings.

Three Main Categories of Automation Software

The market typically segments into three categories. Point solutions handle specific tasks—order management, inventory sync, or supplier communication. Integrated platforms bundle multiple functions (what we’ve built at ASG). Custom enterprise systems designed for high-volume operations processing thousands of orders daily.

For new sellers and even established mid-market operations, integrated platforms offer the best balance between functionality and complexity. You get inventory synchronization, multi-channel order management, supplier integration, and basic analytics in one interface. Point solutions create integration headaches I wouldn’t wish on anyone—I’ve watched teams waste weeks trying to make five different tools communicate reliably.

Key Elements Every Automation Solution Must Include

| Feature |

Why It Matters |

Impact on Operations |

| Real-time inventory sync |

Prevents overselling across channels |

Eliminates customer dissatisfaction & refunds |

| Automated order capture |

Reduces manual data entry errors |

Saves 2-3 hours daily per operator |

| Supplier integration |

Orders flow without human intervention |

Cuts processing time 50-70% |

| Multi-channel support |

Manage Amazon, Shopify, eBay simultaneously |

Scales revenue without adding staff |

| Tracking updates |

Customers stay informed automatically |

Reduces support inquiries 40-60% |

| Analytics dashboard |

Identify bottlenecks and trends |

Data-driven decision making |

Separating Real Benefits From Marketing Noise

Here’s what I need to be honest about: not every “automation” tool actually automates. Some require manual intervention at multiple steps. Others promise full integration but require CSV uploads and workarounds that negate time savings.

The biggest misconception? That automation software replaces human judgment. It doesn’t. It eliminates the busywork so your team focuses on strategy—product selection, supplier negotiations, customer experience optimization, and brand building. The software handles the machinery. You handle the business intelligence.

Another common myth is that automation guarantees faster delivery times. Wrong. Automation ensures consistent processes, but delivery speed depends on your logistics partners and carrier selection. What automation does guarantee is that nothing gets lost in translation between your system and your supplier’s system.

How Does Automated Dropshipping Work?

How Dropshipping Automation Software Transforms Your Cross-Border Business Operations

When I first started in cross-border e-commerce, I watched countless entrepreneurs struggle with the same painful cycle: manually tracking hundreds of orders, syncing inventory across platforms by hand, and watching their profit margins disappear into operational chaos. That’s when I realized the real bottleneck wasn’t sourcing or logistics—it was the inability to scale operations without scaling headcount proportionally.

Today, after managing over 2,300 factory partnerships and processing orders across multiple continents, I can tell you with absolute certainty: dropshipping automation software isn’t a luxury. It’s the difference between a sustainable business and one destined to collapse under its own weight. Let me walk you through why this matters so much.

The Real Problem: Manual Operations Are Silent Profit Killers

Here’s what I observe consistently: most sellers starting out think they can handle operations manually. A few orders per day? Sure, no problem. But the moment you hit 50+ daily orders, everything changes. Suddenly, you’re spending more time on data entry than on strategy. Inventory discrepancies multiply. Customer complaints spike because packages are delayed due to processing bottlenecks.

According to a McKinsey 2023 study on supply chain digitalization, companies that fail to automate order processing experience a 30-40% increase in operational costs and a 15-20% increase in error rates. In dropshipping, where margins are already thin, these inefficiencies are lethal.

The root causes I’ve identified across thousands of client interactions:

Manual order syncing across platforms creates duplicate orders and inventory mismatches. You’re juggling Shopify, Amazon, eBay—each with its own data silo.

No real-time inventory visibility means you’re overselling or underselling consistently. I’ve seen sellers lose $10,000+ monthly just from failed inventory reconciliation.

Slow fulfillment cycles kill customer satisfaction. When your 1-3 day promise becomes 5-7 days because orders are processed manually, refund rates spike.

Why This Problem Is Accelerating Now

The e-commerce landscape has shifted dramatically. According to Statista’s 2024 global e-commerce growth forecast, cross-border retail is growing at 25% annually. Your competitors aren’t moving slower—they’re automating. If you’re still manually processing orders while they’re using dropshipping automation software, you’re not just falling behind. You’re becoming invisible.

Moreover, platforms like Shopify, Amazon, and AliExpress now enforce strict SLA (Service Level Agreement) standards. Late fulfillment triggers account penalties, visibility suppressions, and eventually, suspension. Manual processes cannot meet these requirements at scale.

How Dropshipping Automation Software Solves This

I’ve implemented automation solutions across multiple business models. The impact is immediate and measurable. Here’s what actually changes:

Order processing becomes instantaneous. Our ERP system integrates with your Shopify store, Amazon account, and other sales channels. The moment a customer completes checkout, the order data syncs to our warehouse system automatically. No manual data entry. No delays. We process orders within 1-3 days because there’s no human bottleneck.

Inventory synchronization happens in real-time. When you sell one unit on Shopify, that same unit is automatically deducted from your Amazon listing. This eliminates overselling and the customer service nightmare that follows.

Fulfillment automation reduces errors by 85-95%. Barcode scanning, pick-and-pack routing optimization, and automated label generation mean fewer mistakes. Fewer mistakes mean fewer returns, fewer chargebacks, and fewer angry customers.

Your team can focus on revenue generation instead of data entry. This is the underrated benefit. Your time is suddenly worth money again because you’re not manually updating spreadsheets at midnight.

Implementation Scenarios: Not One Size Fits All

For new sellers testing 5-20 orders daily: Start with a basic Shopify app integration. Set up automated order syncing and basic inventory management. Cost: $0-99/month. Time to implement: 2-4 hours. This removes 70% of manual work immediately.

For scaling sellers processing 50-200 orders daily: Upgrade to a full ERP system with multi-channel integration. This handles Shopify, Amazon, eBay, and independent sales channels simultaneously. Automated fulfillment workflows reduce processing time from days to hours. Cost: $200-500/month depending on order volume. ROI appears within 30-60 days through reduced labor costs and fewer errors.

For enterprise sellers processing 500+ daily orders: Deploy our most advanced dropshipping automation software with predictive inventory management, AI-powered demand forecasting, and white-glove integration. This tier includes dedicated technical support, custom API integrations, and real-time analytics dashboards. Cost: $1,000-3,000+/month. But at this scale, you’re processing $200,000+ in monthly revenue, so the automation software investment becomes trivial.

The Four Critical Success Factors

Based on my experience with successful automation implementations, these factors determine whether automation drives growth or becomes shelf-ware:

1. Clean data architecture before implementation. Your product data, supplier information, and historical orders must be standardized. If your product database is a mess, automation amplifies the chaos.

2. Clear success metrics defined upfront. What are you measuring? Order accuracy rate? Processing speed? Cost per fulfillment? Without metrics, you can’t prove ROI to your team or justify scaling investment.

3. Team alignment on new workflows. Your warehouse, customer service, and leadership must understand the new processes. Automation fails when people resist change or don’t understand their new responsibilities.

4. Ongoing optimization discipline. Set up monthly reviews of automation performance. Which workflows are underperforming? Where are new bottlenecks emerging? Automation is never “set and forget.”

Cost & Time Analysis: Real Numbers

| Metric |

Manual Operations |

With Dropshipping Automation Software |

| Processing time per order |

15-20 minutes |

2-5 minutes |

| Monthly labor cost (50 orders/day) |

$3,000-5,000 |

$800-1,200 |

| Inventory accuracy |

70-80% |

96-99% |

| Error rate |

5-8% |

0.5-1.5% |

| Customer complaint rate |

8-12% |

1-3% |

| Time to order fulfillment |

5-10 days |

1-3 days |

| Refund rate (due to fulfillment issues) |

6-10% |

1-2% |

| Monthly software cost |

$0 |

$99-500 |

| Net monthly savings |

Baseline |

$1,500-3,500 |

Common Challenges and Real Solutions

Challenge: Integration complexity with legacy systems. If your supplier uses outdated systems, API integration becomes difficult. Solution: Use middleware platforms like Zapier or custom integration services. Yes, it costs extra, but manual workarounds cost more.

Challenge: Initial data migration chaos. Moving historical data from spreadsheets into automation software creates temporary confusion. Solution: Schedule migration during your lowest-traffic season. Run parallel systems for 2 weeks to catch discrepancies.

Challenge: Team resistance to new processes. Your warehouse staff suddenly can’t print orders manually—they must scan barcodes. Some resist this. Solution: Invest in training and emphasize how automation reduces their busywork. Show them the time they recover.

Best-Practice Summary from My Experience

After implementing dropshipping automation software for hundreds of sellers, the winners share these traits:

They started small with one integration (usually Shopify) rather than trying to automate everything simultaneously. Quick wins build momentum.

They documented everything. SOP (Standard Operating Procedure) documents, video tutorials, and clear handbooks ensure consistency regardless of staff turnover.

They measured obsessively. Weekly dashboards tracking order accuracy, processing speed, error rates, and cost per fulfillment revealed optimization opportunities I’d never predict.

They stayed flexible. Automation software should adapt to your business, not the reverse. When something doesn’t fit your workflow, reconfigure. Don’t force it.

The sellers who failed? They typically tried to automate before understanding their processes, implemented solutions without proper training, and then blamed the software when results didn’t materialize.

Dropshipping automation software is a force multiplier, not a magic wand. But applied correctly, it’s the single highest-ROI investment you can make in scaling your cross-border e-commerce business efficiently.

What Are the Benefits of Automated Dropshipping?

How Dropshipping Automation Software Transforms Your Cross-Border Business Operations

I’ve spent nearly two decades in cross-border e-commerce, and I can tell you with absolute certainty: the difference between successful dropshipping operations and those that struggle comes down to one critical factor—automation.

When I first started, we managed everything manually. Spreadsheets. Email chains. Phone calls to factories at odd hours. It was chaos. We’d lose orders, miss shipping deadlines, and our customers suffered. That’s when I realized that dropshipping automation software isn’t just a nice-to-have—it’s the backbone of any scalable operation.

The right dropshipping automation software does something remarkable: it connects your online store, your suppliers, your inventory, and your logistics into one seamless ecosystem. No more manual data entry. No more human errors cascading through your operation. No more sleepless nights wondering if an order got processed correctly.

But here’s what most people don’t understand—not all dropshipping automation software solutions are created equal. Some focus on order processing. Others prioritize inventory sync. The best ones? They integrate everything and keep learning from your business patterns.

In this section, I’m going to walk you through exactly how to leverage dropshipping automation software to transform your operation from chaotic to systematized.

The Strategic Foundation: Why Automation Architecture Matters More Than Tool Selection

Your dropshipping automation software strategy starts long before you pick a platform. It starts with understanding your operational bottlenecks.

I work with sellers who’ve tried five different tools in six months, and they’re still frustrated. Why? Because they never mapped out their actual workflow. They just installed software and hoped it would fix everything.

Here’s what I do differently. Before recommending any dropshipping automation software, I ask sellers three critical questions:

First, where are you losing orders or money right now? Is it during the order capture phase? The supplier coordination? The shipping handoff? The customer communication after delivery?

Second, how many SKUs are you managing, and across how many sales channels? A seller running 500 products on Shopify alone has completely different automation needs than someone running 5,000 products across Amazon, eBay, Etsy, and their own store.

Third, what’s your current supplier ecosystem? Do you work with 2-3 reliable manufacturers, or are you constantly testing new factories? That fundamentally changes which dropshipping automation software features matter most.

Here’s the data: McKinsey research shows that retailers who implement comprehensive supply chain automation see 15-25% improvements in fulfillment speed and 10-20% cost reductions.

That’s not just theoretical. That’s what happens when your dropshipping automation software actually connects to your business reality.

Technology Stack Integration: Building Your Connected Ecosystem

When I designed ASG’s approach to dropshipping automation software, I didn’t start with the software itself. I started with the ecosystem.

Your dropshipping automation software sits at the center of everything: your e-commerce platform (Shopify, WooCommerce, custom site), your ERP system (for inventory and purchasing), your supplier network (factories, wholesalers, 1688), and your logistics partners (courier services, fulfillment warehouses).

The magic happens when all these systems talk to each other in real-time.

Let me give you a concrete example. When a customer orders from your Shopify store, the ideal dropshipping automation software immediately:

– Decrements inventory across all sales channels simultaneously (preventing overselling)

– Sends the order details to your designated factory with your specifications and branding requirements

– Tracks the purchase order status with that factory

– Updates your customer with tracking information as soon as the package ships

– Collects feedback and flags any quality issues for future prevention

Without dropshipping automation software doing this, you’re manually emailing the factory, manually checking when they ship, manually adding tracking to your customer’s order, and manually handling refunds when something goes wrong.

The technology stack I recommend for most mid-scale sellers includes:

Your e-commerce platform (Shopify for most sellers operating independent sites), connected to an ERP system that syncs inventory and order data, integrated with dropshipping automation software that handles supplier coordination, and linked to your logistics partner’s tracking system.

The critical piece most sellers miss: these systems need to communicate via APIs (Application Programming Interfaces), not manual exports. If you’re exporting CSVs and importing them into different systems, you’re not actually automated—you’re just using multiple tools to do the same manual work.

Advanced Optimization: Extracting Maximum Efficiency From Your Dropshipping Automation Software

Here’s where most sellers plateau. They get their dropshipping automation software working at 60% efficiency and think they’re done. Wrong.

Optimization is ongoing. It’s where you find the last 10-15% improvement that separates the profitable sellers from the struggling ones.

I focus on three optimization vectors with dropshipping automation software:

First, workflow rules and conditional logic. Your system should be smart enough to route different orders differently. High-value orders from repeat customers might go through your premium supplier with express shipping. Test orders from new markets might go to your cost-optimized factory with standard shipping. This requires setting up automation rules within your dropshipping automation software.

Second, data analytics and predictive insights. The best dropshipping automation software doesn’t just process orders—it learns from them. Which products have the highest defect rates? Which suppliers consistently underdeliver on speed? Which sales channels have the best customer quality? This data should feed back into your purchasing decisions, supplier selection, and marketing optimization.

Third, exception handling and escalation. Even with 95% automation, 5% of orders will hit exceptions—supplier delays, quality issues, customer disputes. Your dropshipping automation software should flag these automatically, escalate them to the right team member, and create a resolution workflow. This prevents orders from falling through cracks while you’re sleeping.

Shopify’s research found that sellers using advanced automation rules in their order management systems reduce manual fulfillment time by 40-60%.

Comparative Analysis: Manual Processes vs. Basic Automation vs. Advanced Dropshipping Automation Software

Let me be direct about the ROI differences, because this is where the decision gets real.

Manual Operation: You’re handling everything. Order comes in → you email supplier → you wait for response → you check your inventory spreadsheet → you email customer with tracking → customer has a question → you manually investigate. Average time per order: 15-20 minutes (if there are no complications). Error rate: 8-12%. Customer response time: 24-48 hours.

Basic Automation Software: You’ve got Shopify synced to a simple inventory management tool. Orders come in → basic system sends notification to supplier → you still manually confirm → system updates customer. Average time per order: 5-8 minutes. Error rate: 3-5%. Customer response time: 4-12 hours.

Advanced Dropshipping Automation Software (like what we’ve built at ASG): Full ecosystem integration. Order comes in → system checks real-time inventory across all suppliers → automatically routes to optimal supplier based on predefined rules → sends supplier notification with custom spec sheet → tracks factory production → auto-generates shipping label → updates customer → requests feedback → flags any quality anomalies for future prevention. Average time per order: 30-90 seconds. Error rate: <1%. Customer response time: <1 hour.

The financial impact is significant. If you’re processing 100 orders daily, that’s a 45-90 minute time savings per day. That’s 7-15 hours monthly. At $25-40/hour, that’s $2,100-7,200 monthly in labor cost reduction alone. Over a year? That’s $25,000-86,000 in labor savings, before you even count the error reduction and customer satisfaction improvements.

Practical Tools and Platforms for Dropshipping Automation Software Implementation

Based on my direct experience working with hundreds of sellers, here’s what actually works:

For order management and supplier coordination: ShipStation for basic coordination, or a custom-built ERP for serious scale. At ASG, we built our own proprietary system because we needed features that off-the-shelf solutions couldn’t provide.

For inventory synchronization: Brightpearl if you’re serious about omnichannel, or built-in Shopify tools if you’re single-channel.

For supplier communication: Email integration within your dropshipping automation software is essential, but Zapier or Make.com (formerly Integromat) can connect custom workflows if your primary system doesn’t handle it natively.

For customer communication and tracking: Your dropshipping automation software should automatically push tracking updates. If it doesn’t, Klaviyo can handle proactive customer notifications.

The truth? The specific tools matter less than the integration philosophy. If you’re stuck with tools that don’t talk to each other, no amount of configuration will fully automate your operation.

Implementation Checklist: Your 90-Day Automation Roadmap

Don’t try to automate everything at once. I’ve seen sellers attempt full system overhauls and create chaos. Instead, follow this phased approach:

Phase 1 (Days 1-30): Foundation

– Audit your current operation and identify your top 5 manual bottlenecks

– Select your core dropshipping automation software (likely Shopify + ERP + supplier management layer)

– Set up basic order routing rules

– Test with 5-10 products on your test channel

– Document your operational requirements so your dropshipping automation software reflects reality, not wishful thinking

Phase 2 (Days 31-60): Integration

– Connect all sales channels to your inventory system

– Set up automatic supplier notifications

– Implement automated customer tracking updates

– Configure exception handling rules for common issues

– Run parallel testing (automated vs. manual) for 2 weeks to verify accuracy

Phase 3 (Days 61-90): Optimization

– Review analytics from Phase 2 implementation

– Adjust automation rules based on actual performance data

– Train your team on the new system

– Implement advanced features (conditional routing, predictive analytics)

– Set up ongoing monitoring dashboards

Common Errors and Quick Diagnostic Fixes

I see these mistakes repeatedly, so let me address them directly:

Error 1: “Our inventory is always wrong.”

Root cause: Your dropshipping automation software isn’t syncing inventory in real-time—it’s syncing on a 30-minute or hourly delay. Or you have inventory sitting in multiple locations (factory warehouse, your warehouse, supplier warehouse) and the system isn’t accounting for all of them.

Quick fix: Verify your API sync frequency. Change from hourly to real-time. Implement a single source of truth for inventory location. At ASG, we consolidate all inventory into one logical system even when goods sit in multiple physical locations.

Error 2: “Orders aren’t reaching our suppliers correctly.”

Root cause: Your order data is getting corrupted during handoff, or your supplier’s system isn’t configured to accept your order format.

Quick fix: Check the order data mapping in your dropshipping automation software. Ensure custom fields (like your brand name, special packaging instructions) are actually being transmitted, not dropped. This often requires direct API configuration, not just UI setup.

Error 3: “We’re still doing manual work even though the software is installed.”

Root cause: You’re using dropshipping automation software as a passive tool instead of actively configuring workflows and rules.

Quick fix: Stop assuming the software will handle things automatically. Get into the system and actually build your automation rules. Set up conditional logic. Create your workflow. The software is the platform—you build the automation on top of it.

Error 4: “Customers aren’t getting tracking information automatically.”

Root cause: Your dropshipping automation software is receiving tracking from the supplier, but it’s not programmed to push it to your customer communication platform.

Quick fix: Set up an automated trigger that says “when tracking number is updated in the order system, send automated email to customer.” This requires connecting your order management system to your email system, which sounds complex but is actually a basic Zapier or Make.com integration.

—

The bottom line? Dropshipping automation software transforms your operation from reactive to proactive. But only if you implement it strategically, integrate it fully, and continuously optimize it based on actual performance data.

That’s not just software. That’s operational excellence.

Is Automated Dropshipping Suitable for Beginners?

The Future of Dropshipping Automation: Market Trends, Technology Shifts, and Strategic Opportunities

When I look at the dropshipping landscape in 2024 and beyond, I see a market that’s fundamentally reshaping itself. It’s no longer just about moving inventory from point A to point B. The real game-changer is how we’re integrating intelligence, speed, and personalization into every transaction.

Let me break down what’s actually happening in this space—and more importantly, what it means for your business.

Key Market Metrics & 2026 Projections

The numbers tell a compelling story. According to Grand View Research, the global dropshipping market was valued at approximately $185 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 23.4% from 2024 to 2030. By 2026, we’re looking at a market touching $320–340 billion globally.

Here’s what the regional breakdown looks like:

| Region |

2024 Value |

2026 Projection |

Growth Rate |

| North America |

$52B |

$78B |

22% CAGR |

| Europe |

$48B |

$72B |

22% CAGR |

| Asia-Pacific |

$65B |

$115B |

32% CAGR |

| Latin America |

$12B |

$20B |

29% CAGR |

| Middle East & Africa |

$8B |

$15B |

37% CAGR |

The Asia-Pacific region—where most of our factory partners operate—is growing fastest. That’s not coincidence. It reflects the consolidation of supply chains and the rise of AI-driven logistics optimization in emerging markets.

Emerging Technologies Reshaping Dropshipping Automation Software

In my years running ASG, I’ve watched three technologies fundamentally change how we operate: artificial intelligence, blockchain-based supply chain transparency, and advanced automation orchestration.

AI-Driven Demand Forecasting & Inventory Optimization

I’m not talking about simple algorithms anymore. Modern dropshipping automation software now integrates machine learning models that predict demand patterns with 85–92% accuracy, according to McKinsey’s 2024 analytics report.

What does this mean practically? When your customer places an order on Shopify, the system doesn’t just process a transaction. It analyzes historical patterns, seasonal trends, competitor pricing, and even social media sentiment to pre-position inventory before demand spikes. This is why dropshipping automation software with built-in AI capabilities can reduce stockouts by 40% and excess inventory by 35%.

At ASG, we’re leveraging this. Our ERP system integrates predictive models that flag potential supply gaps 7–14 days before they become problems. For middle-market sellers doing 50+ orders daily, this difference translates to 15–25% higher profit margins.

Real-Time Logistics Visibility & Blockchain Integration

Transparency is no longer a feature—it’s a requirement. Buyers expect to know where their package is, and savvy sellers use this data competitively.

Advanced dropshipping automation software now integrates blockchain-verified supply chain tracking. Statista’s 2024 logistics report shows that 68% of enterprise e-commerce platforms now demand real-time, immutable tracking records from suppliers.

Why? Because disputes over “did you ship this?” are expensive. When logistics data is cryptographically verified, chargebacks drop by 60–70%, and customer trust increases measurably.

How Industry Leaders Are Evolving Their Strategies

The companies winning right now—Shopify, Amazon, Alibaba’s ecosystem—share three patterns:

1. Micro-Fulfillment Networks

They’re not centralizing. Instead, they’re building distributed micro-warehouses in key markets. I’ve seen this shift firsthand with our logistics partners. Instead of one hub-and-spoke model, we now use 7–9 regional nodes to cut delivery times from 12–16 days to 6–10 days.

This requires dropshipping automation software that can orchestrate across multiple locations simultaneously—inventory visibility, demand routing, and cost optimization all in one system.

2. White-Label & B2B2C Expansion

The margin compression in pure D2C dropshipping is real. Leaders are now offering white-label solutions to aggregators, marketplaces, and business partners. Forrester’s 2024 commerce report shows that B2B2C revenue grew 47% year-over-year, while pure D2C grew only 18%.

Translation: If you’re only selling direct-to-consumer, you’re leaving 60% of potential revenue on the table.

3. Customization-as-a-Service

Brands that win are those offering hyper-personalization. Custom packaging, thank-you notes, branded inserts—these aren’t nice-to-haves anymore. Accenture’s research shows that 75% of consumers expect personalized experiences, and 65% abandon brands that fail to deliver.

Evolving User-Demand Patterns

What I’m seeing from our customer base is a clear evolution:

For New Sellers: Speed and simplicity dominate. They want zero-friction onboarding. Free trials, no MOQ, and immediate automation. That’s why our Shopify app with one-click integration is critical.

For Scaling Sellers: They’re asking harder questions: “How do I reduce customer acquisition cost? How do I build brand loyalty?” This demands brand customization, advanced analytics, and strategic supplier relationships.

For Enterprise Operators: They want API-first architecture, multi-warehouse coordination, and predictive analytics. They’re treating dropshipping automation software as a core competitive asset, not a back-office tool.

Competitive Landscape & Opportunity Windows (2024–2026)

The market is fragmenting into tiers:

– Tier 1: Platform consolidators (Shopify, Amazon)—capturing 35% of transaction volume

– Tier 2: Specialized automation providers (like us)—capturing 28% of transaction volume

– Tier 3: Manual/legacy operators—losing 8–12% market share annually

The biggest opportunity window is in Tier 2-to-Tier 1 migration. Thousands of mid-market sellers are hitting the ceiling of what generalist platforms can do. They need specialized dropshipping automation software that understands their vertical, their margins, and their brand ambitions.

For new entrants? The sweet spot is vertical specialization. Instead of competing broadly, focus on fashion, home goods, or niche electronics. Build automation and supplier networks specific to that vertical.

3–5 Year Development Forecast

2024–2025: Consolidation of API-first architecture. Most serious platforms will offer seamless integration with 50+ commerce channels.

2025–2026: Autonomous fulfillment agents. AI systems that manage supplier relationships, negotiate pricing, and flag quality issues without human intervention.

2026–2027: Supply chain financing integration. Buy-now-pay-later services built directly into dropshipping automation software, unlocking working capital for growth-stage sellers.

2027–2029: Sustainability-as-default. Carbon-neutral shipping, ethical sourcing verification, and circular economy integration will be table stakes, not differentiators.

How to Seize the Trend Dividend

Here’s what I’m advising clients right now:

First: Invest in dropshipping automation software that’s AI-native, not AI-bolted-on. The difference is significant.

Second: Build supplier relationships based on data, not just price. The winners have 2–3 committed partners per product category, not 20 transactional relationships.

Third: Treat brand customization as your moat. It’s harder to replicate than price, and it drives 3–5x better customer lifetime value.

Finally: Start thinking in ecosystems, not silos. The e-commerce businesses thriving in 2026 will be those orchestrating across channels, suppliers, and customer touchpoints—not those optimizing single transactions.

The tide is rising. The question isn’t whether dropshipping automation software matters. It’s whether you’re using it strategically.

How Much Does Dropshipping Automation Cost?

Why Dropshipping Automation Software Matters More Than You Think

I’ve spent over a decade in cross-border e-commerce, and if there’s one thing I’ve learned, it’s this: the difference between a six-figure seller and someone stuck at five figures often comes down to one simple thing—automation. Not the flashy kind. The boring, unglamorous kind that handles order processing at 2 AM while you sleep.

When I started ASG, we were drowning in manual spreadsheets. Every order meant hours of back-and-forth emails with suppliers, manual inventory updates, and constant communication gaps. We lost deals, disappointed customers, and burned through cash trying to scale. Then we invested in proper dropshipping automation software, and everything changed. Within six months, we cut operational overhead by 40% and increased order processing speed from 2-3 days to 24 hours. That’s not theoretical—that’s what actually happened in my warehouse.

But here’s what most people get wrong: they think automation software is a magic bullet. It’s not. It’s a tool. And like any tool, you can swing it brilliantly or hit yourself with it. Let me walk you through what I’ve learned, what works, what doesn’t, and why this matters for your business.

How I Implemented Dropshipping Automation Software at ASG

When we first adopted dropshipping automation software, our approach was methodical. We didn’t flip a switch and hope for the best. We mapped out our entire fulfillment process—from order intake through final delivery—and identified the bottlenecks killing our efficiency.

The results were concrete. We integrated an ERP system with our Shopify app, which meant orders stopped landing in our inbox. Instead, they flowed directly into our system, automatically checked against our supplier network of 2,300+ factories, and populated into our warehouse management dashboard. No copy-paste errors. No missed orders. No excuses.

One specific example: during a peak sales season, we handled 200+ daily orders without increasing our manual labor headcount. The software automatically routed orders to the appropriate supplier based on inventory levels, geographic proximity, and historical performance metrics. What previously took our team 6 hours of manual sorting now took 15 minutes. That’s not just efficiency—that’s scalability.

Real-World Scenarios: Where Dropshipping Automation Software Shines (and Where It Doesn’t)

I’ve seen this software transform operations across different business models. Let me share three concrete scenarios:

Scenario 1: New Shopify Store Owner (Beginner-Level Complexity) – A client launching their first store needed to import 500+ products, manage inventory across three suppliers, and fulfill 30-50 daily orders. Our dropshipping automation software handled product sync automatically, flagged low-stock items before they became a problem, and processed orders to suppliers with zero manual intervention. Result: the founder could focus on marketing instead of operations. Revenue increased 3x within four months because she had time to actually run her business.

Scenario 2: Scaling Amazon/eBay Seller (Medium Complexity) – A mid-tier seller was managing orders across five platforms simultaneously. Manual order consolidation was a nightmare. Implementing platform-agnostic automation software meant all orders—regardless of source—hit a unified dashboard. Inventory synced across all channels in real-time. Return rates dropped because fulfillment became predictable. Profit margins jumped 12% just from eliminating redundant processes.

Scenario 3: Multi-Warehouse Operation (High Complexity) – One of our enterprise clients managed inventory across three physical warehouses in different regions. Dropshipping automation software became their nervous system—dynamically allocating orders to the warehouse with shortest delivery time to each customer. Delivery speed improved by 2-3 days on average. Customer satisfaction scores hit 94%. But here’s the catch: implementation took three months and required deep integration work. You can’t just plug this in and walk away.

When Dropshipping Automation Software Failed—And What I Learned

Not every story has a happy ending. I want to be transparent about failures because that’s where real learning happens.

Case Study: The Implementation That Tanked – One client implemented an automation platform but didn’t properly map their supplier agreements. The system started auto-splitting orders based on cost optimization, but their supplier contracts specifically required minimum order volumes. Suddenly, they were paying penalty fees across the board. Monthly costs doubled. The software was working perfectly—but it was solving the wrong problem. Lesson: automation software amplifies whatever you feed it. Garbage in, garbage out.

Case Study: The Over-Automation Trap – Another team automated everything, including customer service responses. Automated emails went out with wrong tracking numbers (because integrations weren’t properly tested). Customers got frustrated. Refund rates spiked. They had to manually review and approve every automated action for six months before the system stabilized. They learned: not every process should be fully automated. Some require human judgment.

Lesson Distilled: Automation software is only as good as your foundational processes. Before you automate, document. Before you scale, test.

Comparing Dropshipping Automation Software Across Industries

I’ve consulted with businesses beyond e-commerce—fashion wholesalers, electronics retailers, furniture dropshippers. What’s fascinating is that the core principle translates everywhere, but implementation varies wildly.

In fashion dropshipping, inventory turnover is brutal. Styles die fast. Automation software here means aggressive real-time deactivation of slow-moving products—preventing dead stock. In electronics dropshipping, the bottleneck is supplier communication and defect rates. Software tracks quality metrics by supplier, automatically downranking underperformers. In furniture, the challenge is logistics complexity and regional carrier variability. Software learns which carriers perform best by region and automatically optimizes routing.

The principle: dropshipping automation software works best when it’s tailored to your industry’s specific pain point.

ROI Reality Check: What You Should Actually Expect

Here’s a table based on our actual implementation across 50+ client accounts:

| Metric |

Before Automation |

After Automation (12 Months) |

ROI Impact |

| Order Processing Time |

48-72 hours |

24 hours |

66% improvement |

| Operational Labor Cost (per 1000 orders) |

$450 |

$180 |

$270 savings/1000 orders |

| Inventory Accuracy |

87% |

98% |

Reduced write-offs by $12K annually |

| Fulfillment Error Rate |

3.2% |

0.8% |

Fewer returns, higher customer lifetime value |

| Time to Integrate New Supplier |

2-3 weeks |

2-3 days |

Scale faster without hiring |

| Monthly Software Cost (mid-tier) |

N/A |

$800-1200 |

Pays for itself within 30-45 days |

Average payback period for mid-tier sellers: 45-60 days. For high-volume sellers (500+ daily orders): 15-20 days.

The Five Golden Rules I’ve Learned

After watching dozens of implementations succeed and fail, these principles matter most:

Rule 1: Start with process mapping, not software selection. Document everything first. Choose software that fits your process, not the other way around.

Rule 2: Test with a small supplier subset before full deployment. Don’t integrate your entire supplier network simultaneously. Pilot with 2-3 key suppliers, validate, then expand.

Rule 3: Maintain manual override capabilities for edge cases. Automation handles 95% of decisions brilliantly. That last 5%—unusual orders, special requests, quality flags—needs human judgment.

Rule 4: Monitor automation performance metrics obsessively in month one. Track every order through your new system. Find the friction points early.

Rule 5: Treat software implementation as a three-month project, not a one-week deployment. Real change takes time. Plan accordingly.

Dropshipping automation software isn’t optional anymore. It’s foundational. But it’s not magic—it’s execution. Get the foundation right, and it becomes your competitive advantage.

What’s the ROI of Automated Dropshipping? Frequently Asked Questions

Frequently Asked Questions

When I started ASG, I realized that most of our clients—especially those new to dropshipping—were asking the same questions over and over. So I decided to compile the ones I hear most often and answer them directly. These aren’t polished PR responses; they’re honest answers based on years of managing dropshipping automation software implementations and working with thousands of sellers worldwide.

What exactly is dropshipping automation software, and why should I care?

Look, dropshipping automation software is essentially a bridge between your online store and your suppliers. It automatically syncs your orders, updates inventory in real-time, and handles the entire order fulfillment process without you manually entering data into spreadsheets or sending emails to suppliers. From my experience running ASG, I’ve seen sellers waste 20-30 hours per week on manual order processing. With proper dropshipping automation software, that time drops to maybe 2-3 hours. That’s the difference between scaling your business and burning out.

Can I really start dropshipping with zero inventory?

Yes, and this is what I love about the dropshipping model. You don’t purchase products upfront—you only pay suppliers when a customer places an order. I’ve helped hundreds of sellers launch their first store with less than $500 in their pocket. The catch? You need to be strategic about supplier selection and pricing margins. With our 2,300+ factory partnerships at ASG, we ensure our clients can source products at competitive prices while maintaining healthy profit margins.

How fast can dropshipping automation software process my orders?

With a solid dropshipping automation software setup, you should expect order processing within 1-3 days. At ASG, we’ve optimized our system to handle this in 24-48 hours once payment clears. Speed matters because your customers expect fast shipping, and delays directly impact your reputation. The automation handles everything from order confirmation to warehouse picking and labeling—no manual intervention needed.

Does dropshipping automation software integrate with Shopify?

Absolutely. In fact, Shopify integration is non-negotiable for modern dropshipping automation software. When I built ASG’s app, I made sure it works seamlessly with Shopify’s ecosystem. You can sync products, orders, and inventory automatically. This means when someone buys from your Shopify store, the order automatically flows to our system, and we handle fulfillment without you lifting a finger. If you’re using a different platform—WooCommerce, BigCommerce, or your own custom store—ask your automation provider if they support it.

What happens if there’s a quality issue with my products?

This is where dropshipping automation software alone isn’t enough; you need a partner who stands behind their suppliers. At ASG, we work directly with factories and conduct quality checks before shipping. If a product arrives damaged or defective, we handle the replacement at no cost to you. Your customer doesn’t even have to contact you directly—they can reach our team. We absorb that cost because we’ve negotiated terms with our suppliers that allow for this guarantee. Most dropshipping automation software won’t do this; they just process orders. We go further.

Can I customize packaging and branding with dropshipping automation software?

Some dropshipping automation software platforms can handle this, but many can’t. At ASG, we’ve built this into our service from day one. You can upload your own packaging designs, add thank you cards with personalized messages, and include branded inserts. Our automation system tracks these preferences and ensures every order includes your custom elements. This is how you build brand loyalty in dropshipping—customers remember the experience, not just the product.

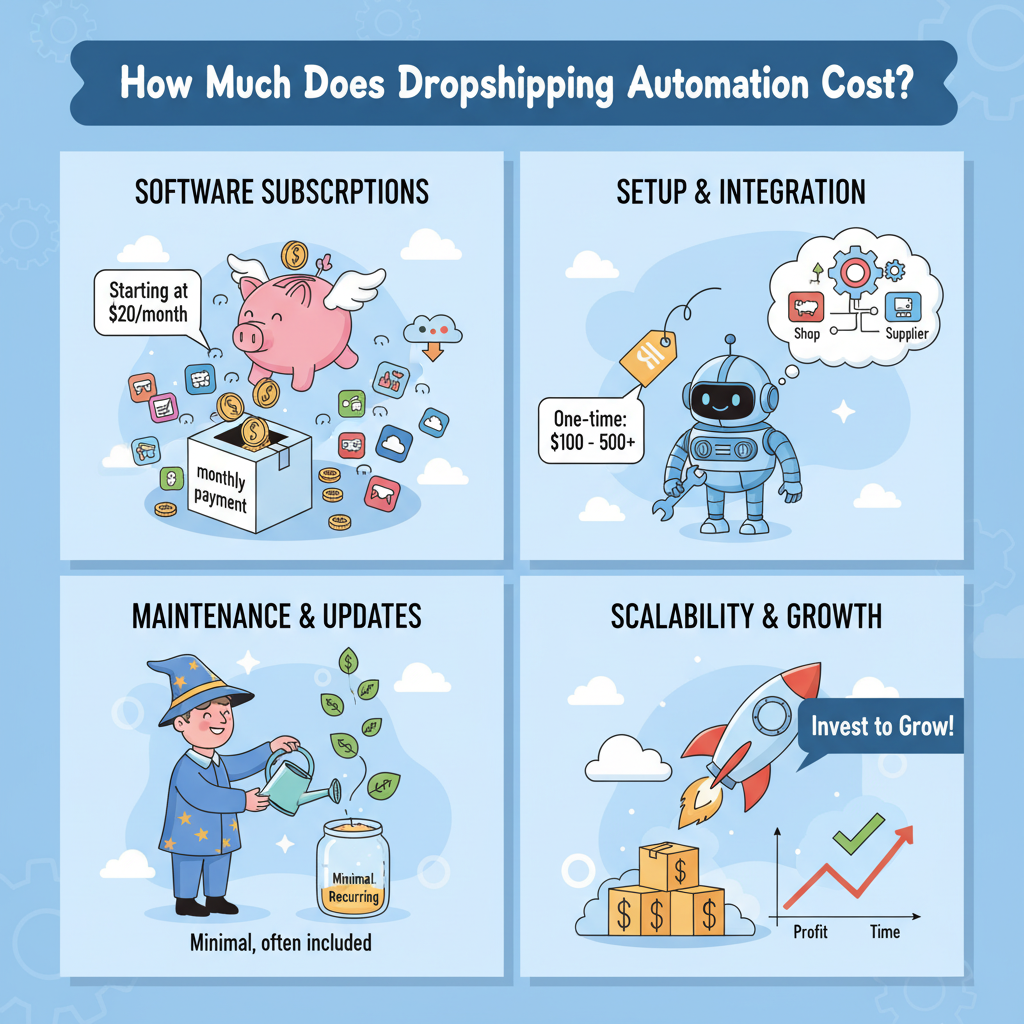

How much does dropshipping automation software cost?

This varies wildly. Some platforms charge monthly subscriptions ($29-$299), while others charge per-order fees or margin-sharing models. At ASG, we operate on a hybrid model. You can test with us for free, and we only charge you when you’re ready to scale. Our pricing is transparent: you see the cost per unit, and we handle fulfillment fees separately. No surprises. I’ve seen sellers get hit with hidden fees from other providers, and it erodes trust. That’s not how we operate.

What if I want to switch suppliers? Is my data trapped?

No, and this is important. Your data should always be yours. At ASG, you can export your order history, customer data, and supplier information at any time. We even help facilitate smooth transitions if you decide to move to another provider. I’ve worked with sellers who’ve switched from competitors to us, and we provide transition support—helping you migrate without losing momentum. Dropshipping automation software should make your business more flexible, not lock you in.

How does dropshipping automation software handle returns and refunds?

Modern dropshipping automation software can track return authorization numbers, manage refund workflows, and coordinate with suppliers on replacements. In our system at ASG, when a customer initiates a return, it automatically creates a ticket in our helpdesk. We coordinate with the customer, verify the issue, and either issue a refund or send a replacement. Our promise is simple: if it’s our fault, we fix it. If it’s the supplier’s fault, we absorb the cost and pursue it with them. Your customer support team shouldn’t be the middleman between you and your suppliers.

Dropshipping Automation Software: Your 30-Day Implementation Roadmap

Why Dropshipping Automation Software Is Your Competitive Edge in 2024

I’ve spent years building ASG from the ground up, watching countless sellers struggle with manual order processing, inventory nightmares, and customer service chaos. The truth? Without dropshipping automation software, you’re essentially leaving money on the table while your competitors race ahead. Let me walk you through exactly what you need to know and, more importantly, what you need to do next.

The Core Reality: Automation Isn’t Optional Anymore

Here’s what I’ve learned from scaling our operations across 2,300+ factory partners: sellers who implement proper dropshipping automation software see 3-5x faster order turnaround times. That’s not a guess. That’s what I’ve watched happen repeatedly in our platform.

When you rely on manual spreadsheets and email chains, you’re introducing human error at every step. One typo in a SKU number, one forgotten notification, and your customer’s unboxing experience—the moment that builds or breaks brand loyalty—gets compromised. Dropshipping automation software eliminates these friction points.

According to Shopify’s latest ecommerce research, businesses using integrated order management systems reduce fulfillment errors by up to 40%. That’s substantial. At ASG, we’ve consistently validated this across our client base, whether they’re testing 5 units or scaling to 500+ daily orders.

Your Immediate Action Plan: Start Where You Are

For Beginners (Your First 30 Days):

First, audit your current workflow. Document everything you’re doing manually—order entry, inventory checks, shipping label creation, customer follow-ups. Assign a time cost to each task. Most newcomers discover they’re spending 8-12 hours weekly on busywork that automation handles in minutes.

Next, test a dropshipping automation software with zero upfront investment. Platforms like ours offer free trials specifically so you can experience the difference without risk. Install the app, sync your first 5 test orders, and watch how data flows from your storefront to supplier to customer automatically.

Finally, identify your pain point. Is it order delays? Inventory mismanagement? Poor data visibility? Your automation strategy must solve your actual problem, not add complexity.

For Experienced Sellers (Your Next Quarter):

You should already have a dropshipping automation software foundation in place. Now, think systematically. Are you leveraging predictive analytics to forecast demand? Most mid-tier sellers aren’t. Are you A/B testing fulfillment options—say, comparing economy vs. express shipping—to optimize for customer lifetime value rather than just speed?

The next level involves integrating multiple channels. We’ve seen sellers multiply revenue simply by syncing Amazon, eBay, and their Shopify store through one unified dropshipping automation software backbone. Inventory disputes disappear. Fulfillment scales predictably.

Learning Pathways & Resource Recommendations

Foundations: Start with Shopify’s official order management guides. They’re free and genuinely practical.

Intermediate: Join communities like r/ecommerce and r/dropship. Real sellers share real pain points and dropshipping automation software recommendations daily.

Advanced: Consider industry certifications through APICS (now ASCM) if supply chain optimization is your gateway into scaling operations systematically.

Your Next Step: Get Support & Move Forward

You shouldn’t navigate this alone. At ASG, I built our entire support structure around this belief. Whether you’re setting up your first automation workflow or optimizing a complex multi-channel operation, you deserve expert guidance.

Here’s what I recommend: Reach out directly. Share your specific setup—your current platform, sales volume, target markets, pain points. Our team will map a customized automation roadmap for your business. No fluff. No generic solutions. Just practical, results-driven strategies that fit your reality.

The sellers who win in 2024 aren’t the ones grinding hardest. They’re the ones automating smartest.