Hey friend! I know dropshipping can sometimes drive you crazy: you’ve invested in ads, the data looks good, but you still crash due to logistics delays, quality issues, or cost overruns. As someone who’s been grinding in ASG for years and helped countless sellers, I’ve discovered that 90% of failures aren’t due to bad luck—it’s the supply chain that drags you down. Today I want to have a real conversation with you about what’s really happening behind the scenes, using real cases to help you avoid these pitfalls.

The biggest reason dropshipping friends fail is actually supply chain issues:

- • Logistics slower than molasses: 30 days to delivery, customers have already refunded and left bad reviews—who has patience to wait that long?

- • Uncontrolled costs: Purchase prices can differ by 30%-50%, eating up all your already thin profits

- • Terrible customer experience: You know what? 70% of bad reviews aren’t actually about product quality, but about sloppy packaging, opaque logistics info, and poor after-sales service.

This is just the tip of the iceberg! Next, I want to chat with you about those nine hidden killers that can make sellers crash and burn—things like sudden peak season price hikes, inaccurate inventory data, missing compliance certificates, and more. I’ll also share some practical methods, like how to find backup factories, establish quality control processes, and use automation systems to minimize risks. Don’t scroll away just yet—the real valuable stuff is coming up.

Let’s Talk Deep About Why Supply Chains Are So Prone to Problems

Honestly, while advertising is important, it’s really not the root cause of dropshipping failures—supply chain is the real boss. Many friends think supply chain is just “shipping stuff,” but there’s actually a ton of complexity here! From product selection to sampling, purchasing, warehousing, quality control, packaging, shipping, all the way to after-sales service—every step could hide a pitfall that makes you crash.

What’s most deadly is that these problems are invisible during normal times, often only surfacing at critical moments when it’s already too late. Over the years, I’ve seen too many independent website friends, Amazon sellers, and TikTok superstars who were killing it, only to fall into these invisible traps. Let’s go through these nine hidden killers one by one—I’ll tell you how they screw people over and how to prevent them.

1. Slow Logistics: Customers Really Can’t Wait

Dropshipping friends should all relate to this—whether you’re selling chairs, headphones, or pet supplies, the first question customers ask after ordering is always “When will it arrive?” Western buyers really have zero patience; they can wait maybe 5-7 days on average,

and after two weeks they start freaking out. I’ve seen too many newcomers trying to save on shipping costs by choosing sea freight or “economy channels,” resulting in 30+ day delivery times. This isn’t saving money—you’re digging your own grave! Refunds, bad reviews, complaints—they all come flooding in. You know what? For every extra week of shipping time, repeat purchase rates drop by 15%-20%.

To be honest, after all these years, I’ve found that fast, stable logistics brings more long-term benefits than throwing money at ads. Like our ASG overseas warehouses and dedicated shipping channels—we can get to major US cities in 6-10 days,

and Europe/Australia in 8-12 days. Don’t underestimate this few-day difference. When you can tell customers “about a week to delivery,” their willingness to order and likelihood to repurchase increases dramatically.

How to solve this problem? It’s actually simple:

- • Don’t choose “turtle-speed logistics” to save a few bucks on shipping—capturing customers’ hearts matters way more than saving that bit of money

- • Find reliable logistics partners, whether it’s service providers with their own warehouses or courier companies you’ve worked with for years—the key is ensuring tracking info updates promptly and speed stays consistent

- • Always send customers tracking numbers ASAP. You know what? The moment customers get that tracking number, they feel relieved—this small detail gets overlooked by so many people

2. Purchase Prices Too High: This Really Is Life-or-Death Stuff

Imagine this: you and your competitor are both selling the same Bluetooth headphones, but they’re making bank while you’re losing money. Feel terrible, right? The problem often comes down to purchase prices. Many friends are still using old-school methods—getting samples on AliExpress, then placing bulk orders directly on Alibaba—ending up getting charged 30%-50% more by suppliers.

Let me give you a real example: same Bluetooth headphones, some people pay 28. That’s a 1,700 in difference. Keep this up and it’s really night and day!

I once helped an independent website friend who sold handheld vacuums—moving 1,000 units monthly but with costs 20% higher than competitors, leaving razor-thin profits.

We helped him find two factories for requoting and signed long-term cooperation agreements. His purchase prices dropped 25% directly, instantly doubling profits. This taught me that cost control isn’t about simple haggling—it requires professional supply chain integration:

- • Don’t just stare at platform quotes—find multiple channels for comparison to discover truly low-cost sources

- • When negotiating with suppliers, use data to talk—things like your sales estimates and long-term cooperation sincerity can help you get better prices

- • When budget allows, consider appropriate stock-building to lock prices, especially before peak seasons

3. Terrible Customer Experience: Actually Many Bad Reviews Have Nothing to Do with Product Quality

Many dropshipping friends see bad reviews and immediately think there’s a product quality issue, but that’s not the case. Data tells us that over 70% of bad reviews actually have nothing to do with the product itself—they’re because of careless packaging, slow logistics, opaque tracking info, and poor after-sales attitudes.

Think about it: customers buy your skincare products, but when they receive them, the outer packaging box is crushed and deformed, products scattered everywhere, with several bottles leaking liquid all over. Even if the product itself is fine, just that unboxing experience is enough to turn people off.

I particularly remember a friend selling skincare sets whose repeat purchase rate was stuck at 20%—couldn’t get it higher no matter what. Later we helped them redesign packaging boxes, added handwritten thank-you cards, and upgraded logistics (using reinforced packaging and better shipping channels).

Guess what? Three months later, repeat purchase rates jumped straight to 55%! What does this show? Good customer experience can make ordinary products feel “high-end.”

Actually, creating good customer experience isn’t that hard:

- • Put some effort into packaging: even just sticking on a simple logo sticker makes customers feel you care

- • Make logistics info transparent: when customers can check where their package is anytime, they feel at ease. You know what? They really get anxious when there’s no tracking info

- • Add little touches to packages: a thank-you card or small gift—low cost but can greatly boost repeat purchases

- • Do after-sales service properly: when customers have issues, respond quickly and solve them actively instead of passing the buck

4. Peak Season Price Hikes: Wanted to Make Money, Ended Up Getting Fleeced by Suppliers

Every Black Friday, Christmas, Thanksgiving and other big promotions, you think it’s time to make money, but suppliers aren’t dumb either—seeing demand explode, they start hiking prices. During last year’s Black Friday, average increases were nearly 30%, with some raw materials jumping 50% overnight!

Those successful big sellers learned smart long ago—they lock in prices 2-3 months early, using long-term contracts to tie down suppliers. But many smaller players lack this awareness, rushing to place orders only when peak season approaches, falling into the “sell more, lose more” trap.

How to avoid this situation?

- • Start preparing three months early: estimate how much you can sell during peak season and sign fixed-price contracts with suppliers in advance

- • Don’t put all eggs in one basket: find 3-5 factories as backups—when one raises prices, immediately switch to the next

- • When negotiating, grab suppliers’ pain points like long-term cooperation and payment terms to get better prices

5. Advertising Dependency Trap: Throwing More Money Can’t Save Turtle-Speed Logistics

Many friends put all their hopes on advertising, thinking they just need to throw money at traffic to make money. Honestly, if your supply chain has problems, throwing more money at ads only amplifies your weaknesses.

There’s an interesting data point: ad conversion rates and delivery speed are directly proportional—faster delivery means better ad performance; slow logistics makes ad ROI go straight to zero.

I have a friend who spent tens of thousands on Facebook and TikTok promoting coffee machines, but because logistics used sea freight, customers had to wait a month to receive goods. Final refund rate hit 40%, and all ad spend went down the drain.

How to avoid this trap?

- • Ad budget must match your supply chain capabilities—never blindly increase spending when supply chain can’t keep up

- • Monitor both ad data and logistics data simultaneously—when ROI drops, first check if there are supply or delivery issues, don’t rush to increase budget

- • Get customer experience right first before throwing money at traffic—once customer satisfaction and repeat rates stabilize, then scale up advertising for doubled effects

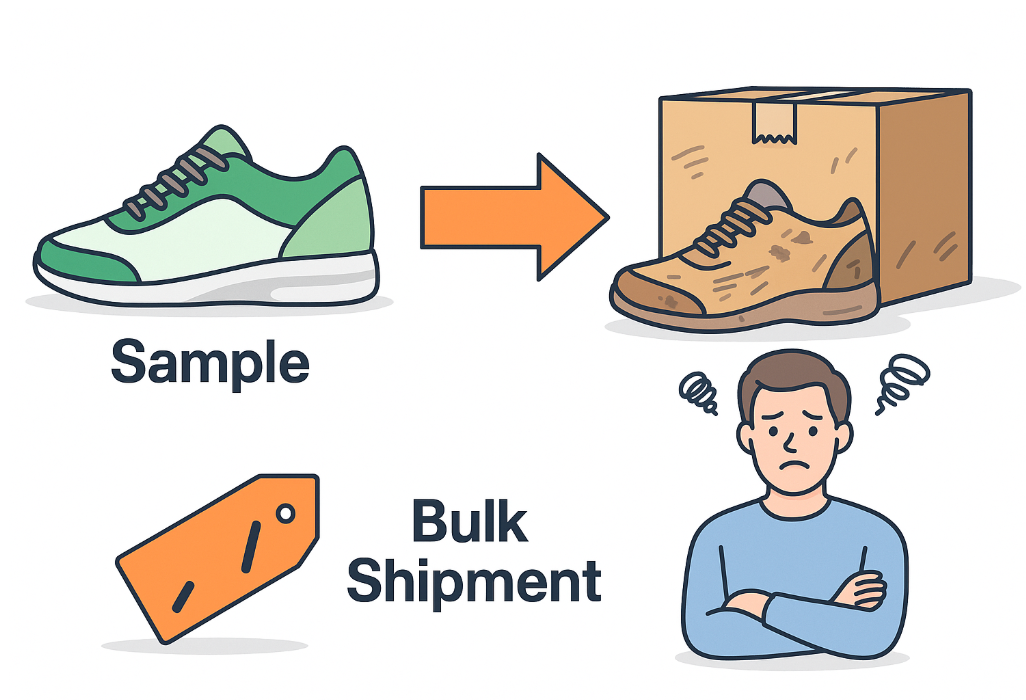

6. Samples and Bulk Orders Don’t Match: This Hurts Customers’ Hearts Most

When doing dropshipping, samples are customers’ first impression of products. If samples look great but bulk order quality gets watered down, customers feel scammed. You know what? 30% of newbie friend refunds are due to “goods not matching description.”

Those successful big sellers treat samples like contracts, clearly stipulating that samples and bulk orders must be identical—otherwise free returns or compensation. Some sellers I’ve helped even proactively promise “full refunds for inconsistencies,” actually winning customers’ long-term trust.

So here’s what to do:

- • Find reliable suppliers, clearly requiring samples and bulk orders to use identical raw materials and processes

- • Write it black and white in contracts that “samples are the standard”—no random material substitutions or process changes allowed

- • Establish “inconsistency equals refund” mechanism: when problems occur, proactively refund customers or reship, building trust this way

7. Inventory Data Chaos: Shows In Stock, But No Inventory When Customers Order

Inaccurate inventory data is another headache-inducing problem. Many friends still use manual bookkeeping or Excel spreadsheets to manage inventory.

Once sales channels multiply and order volumes increase, data easily gets out of sync. You know what? Order cancellations due to inaccurate inventory can drop repeat purchase rates by over 50%!

I know a friend selling women’s clothing whose inventory management was a total mess—rooms full of unsold seasonal clothes while hot items frequently went out of stock, eventually losing all customers.

How to solve this problem?

- • Use professional ERP systems or e-commerce systems for real-time inventory syncing: sell one, automatically subtract one, ensuring all platform inventory data is accurate

- • Do frequent small restocks instead of bulk hoarding—avoids dead inventory while not tying up too much capital

- • Set safety stock alerts so the system automatically reminds you to restock when inventory runs low

8. Missing Compliance Certificates: One Mistake Gets Your Entire Store Delisted

Dropshipping products must comply with regulations in various countries—this really can’t be taken lightly. Like Europe needs CE certification, US needs FDA certification, and some states have special requirements for electronics. Last year, 20% of Amazon delistings were due to missing compliance certificates.

I know of a smart bracelet store that got fined $10,000 and suspended from sales for ignoring California’s Proposition 65 law. Many newcomer friends think “if others can sell it, so can I,” but once platforms catch you, it’s too late for regrets.

My recommendations:

- • List required certifications for target markets before product launch and prepare them in advance

- • Confirm with suppliers whether products have passed relevant regulatory testing—choose manufacturers with credentials when possible

- • If third-party test reports are needed, book in advance—don’t wait until platforms demand them to scramble

- • Treat compliance costs as moats: higher compliance barriers mean harder entry for competitors and more stable profits for you

9. Financial Security: Most Afraid of Suppliers Running Away

Many friends have experienced this nightmare: money paid, but suppliers vanish into thin air, or goods arrive with terrible quality. Data shows 30% of newcomers experience financial risks in their first two years. I had a friend who prepaid $50,000 to a watch factory, only for them to disappear overnight—money gone and missed the entire selling season.

How to avoid this nightmare?

- • Use third-party escrow or credit guarantee services: release payment only after goods pass inspection—suppliers have no incentive to run

- • Make staged payments: pay corresponding amounts after completing each phase instead of throwing all money in at once

- • Investigate supplier backgrounds in advance: check business licenses, factory photos, customer reviews, etc., ensuring stable operations

Delivery and Customer Experience Traps

After understanding the nine hidden killers, we can break them down by theme to explore the logic and solutions behind them more deeply. First are traps directly related to delivery and customer experience—this includes slow logistics, poor customer experience, and false inventory.

Delivery Speed and Logistics Strategy

Some sellers naively think all customers are willing to wait a month for delivery, or believe that with good products and advertising, customers will patiently wait. The reality is quite the opposite. Foreign buyers have very low tolerance for delivery times—especially with Amazon Prime, Temu and other platforms educating consumers about “order today, arrive in two days” habits. If your products take 30 days to arrive, no matter how big a discount you offer, customers will still complain.

Why is delivery speed so important?

- • Reduces refund rates: When customers receive goods within 5-7 days, refund rates typically stay below 5%; once it exceeds 2 weeks, refund rates spike to over 20%

- • Improves review rates: Many users leave positive reviews immediately after receiving goods—fast shipping enhances their shopping satisfaction

- • Increases repeat purchase rates: Sellers with fast delivery more easily get customers to buy again, especially for repeat consumption categories

How to improve logistics efficiency?

- 1. Choose appropriate shipping methods: For light, small items, use commercial express or air mail; for large, low-priced products, consider overseas warehousing + local delivery—guarantees speed while saving shipping costs

- 2. Reserve sufficient processing time: Don’t wait for customers to ask before shipping—prepare packaging in advance, achieve same-day or next-day shipping

- 3. Real-time transparent logistics info: Embed logistics tracking interfaces in order systems, letting customers check package status anytime, reducing pressure on your customer service

- 4. Forward-deploy inventory: Pre-stock hot products in overseas warehouses near target markets to dramatically shorten delivery times

As someone who’s been deep in supply chain for years, I always emphasize: fast, stable logistics is dropshipping sellers’ moat, not an extra cost. ASG uses multi-warehouse coordination and professional supply chain systems, ensuring most orders deliver within 6-10 days while providing complete visual tracking to reduce customer anxiety.

Packaging, Customer Experience, and Brand Building

Many sellers overlook packaging importance, thinking it’s costly and unnecessary. I often get asked: “Janson, does custom packaging really make that big a difference?” My answer: Absolutely! In Western markets, consumers aren’t just buying products—they’re buying experiences. A thoughtfully designed packaging box, a considerate thank-you card, even a sticker—all communicate your brand value and professionalism. Statistics show products with branded custom packaging see 30%-60% average increase in repeat purchase rates.

Key points for creating outstanding customer experience:

- • Custom packaging and brand story: Embed your brand story or values in packaging design, letting customers know who you are and why you’re trustworthy. For example, if you focus on eco-friendliness, include a card explaining your use of biodegradable materials

- • Details determine feelings: Don’t let products rattle around in packages—avoid damage or liquid leaks. For fragile items, use bubble wrap and reinforced boxes; for liquids, add sealing measures

- • After-sales communication: Include after-sales cards in every package, telling customers how to contact you with any issues while expressing gratitude and care. This not only reduces bad reviews but improves brand perception

- • User-Generated Content (UGC) incentives: Encourage customers to share photos in packaging—provide random small gifts or discount coupons, guiding them to share your products and packaging experience on social media. This generates more user feedback and free promotion

When customers receive beautiful packages, that unboxing ritual creates deep brand impressions. You’re not just selling products—you’re providing shareable experiences. Data shows 40% of users willing to share photos leave positive reviews because of packaging, bringing in more new customers.

Inventory and Order Management: From Chaos to Efficiency

Inventory management is a challenge for many dropshipping beginners. Orders come from different channels—Shopify, Amazon, TikTok, Facebook Shop… Relying purely on manual bookkeeping or spreadsheets easily leads to overselling or inventory buildup. I once saw a women’s clothing seller who, due to inventory desynchronization, exploded sales of a new dress on TikTok—actual inventory was only 20 pieces but sold 100, forcing cancellation of 80 orders and triggering massive bad reviews.

The key to solving this problem is using automated order and inventory management systems:

- 1. Unified platform management: Connect all sales channels to the same ERP or management system for synchronized inventory and order data updates. For example, when you sell a product on Shopify, the system automatically subtracts one from total inventory while updating Amazon or TikTok inventory

- 2. Set safety stock lines: Establish alert values for each SKU—when inventory drops below this level, the system automatically reminds you to restock, avoiding stockouts affecting sales

- 3. Reasonable restocking plans: Create restocking plans based on sales history and trend predictions, avoiding excessive hoarding that ties up capital. You can also negotiate staged deliveries with suppliers

- 4. Data-driven decisions: Regularly check inventory turnover rates, slow-moving product reports, and other data to determine which products need clearance or promotion, which need increased stocking

Using systematic inventory management not only reduces labor costs but dramatically lowers error rates and improves customer satisfaction. ASG’s ERP system integrates with major platforms for full automation, letting sellers focus energy on products and marketing instead of tedious manual updates.

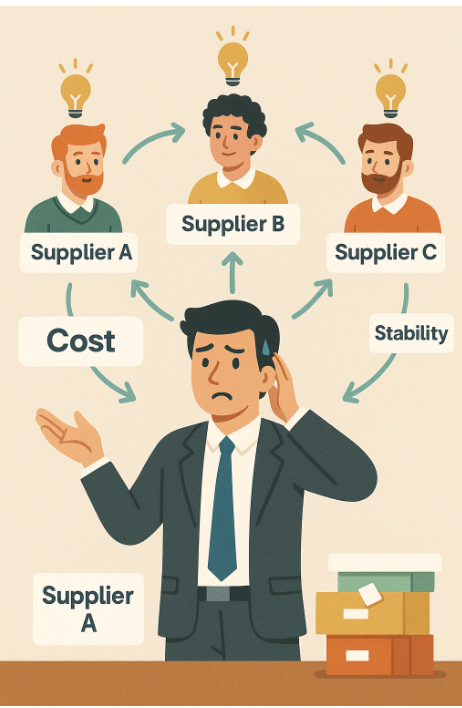

Cost and Supplier Management Traps

A major supply chain challenge lies in cost and supplier management—this covers purchase prices, supplier stability, peak season price hikes, and sample consistency issues. Master these keys to maintain advantages in price wars while ensuring stable product supply.

Price Negotiation and Sourcing Strategy

Many newcomer sellers lack bargaining power initially, passively accepting supplier quotes. I often hear complaints like: “Others can get it for 45?” Actually, price negotiation isn’t just “haggling”—it’s an art requiring preparation, patience, and long-term cooperation.

Effective price negotiation strategies include:

- 1. Understand market benchmark prices: Check prices across multiple platforms like AliExpress, 1688, local overseas wholesalers to understand rough market price ranges. Having bottom prices gives negotiation confidence

- 2. Volume estimates and long-term cooperation: Suppliers prefer offering discounts for large orders. If you can provide sales estimates or sign long-term cooperation agreements, they’re more likely to lower unit prices

- 3. Multi-supplier comparison: Contact 3-5 potential suppliers simultaneously, compare quotes with data, then negotiate with preferred partners for optimal prices

- 4. Value-added negotiations: Beyond unit prices, negotiate warranty periods, return policies, future restocking priority, etc., increasing overall cooperation value. Even with similar unit prices, good after-sales and restocking conditions offer huge advantages

Long-term, professional supply chain management teams are needed to truly control costs. For example, our ASG supply chain team has over 150 professionals and cooperates with 2,300+ factories, quickly matching suitable factories when customer orders scale up, dramatically reducing procurement costs.

Supplier Stability and Multi-Source Strategy

If you only have one supplier, when they get overwhelmed, raise prices, or have problems, your business gets forced to shut down. I’ve met many sellers who faced massive stockouts due to suppliers suddenly stopping production or raising prices, missing peak season sales. Top seller experience tells us supplier backup and multi-source strategy are the only way to improve supply chain stability.

How to build stable supplier networks?

- • Establish supplier evaluation systems: Score each supplier based on on-time delivery, quality stability, reasonable pricing, and communication efficiency—promptly eliminate poor performers

- • Set primary and secondary suppliers: Core products need at least 2-3 main suppliers plus 1-2 backups for when main suppliers lack capacity or face emergencies

- • Sign long-term contracts: For well-performing suppliers, sign long-term cooperation agreements, exchanging stable orders for price advantages and production priority. Set price fluctuation ranges in contracts to avoid peak season price hikes

- • Deep supplier cooperation: Like jointly developing new products with factories, pre-locking production lines, forward-deploying capacity before peak seasons—this not only reduces risks but makes factories value your orders more

Ensuring Sample and Bulk Order Consistency

Preventing sample-bulk inconsistencies requires strict communication and quality control processes beyond clearly stating “samples are contracts”:

- • Detailed sample recording: Include material, process, color, size, weight parameters—take high-resolution photos and videos when necessary; let suppliers know any deviations will be caught

- • Mid-production sampling: Extract some products for quality checks during batch production, providing timely feedback to factories to avoid discovering bulk order failures at the last moment

- • Pre-shipment final inspection: Confirm bulk orders match samples before releasing shipments—immediately rework or reproduce if problems found

Real case: A pet supplies seller initially ignored bulk-sample differences, receiving massive customer complaints. We helped establish three inspection procedures, recording quality check data for each batch. In just two quarters, return rates dropped from 8% to under 1%, with dramatically improved customer satisfaction.

Preventing Peak Season Price Hikes and Cost Fluctuations

Peak season price hikes can be solved through advance price-locking and multi-supplier strategies mentioned earlier. Additionally, you can use futures purchasing and staged payments to smooth capital pressure and price risks. For example, sign one or two-year fixed-price contracts with suppliers, prepaying deposits to lock raw material prices. Or use financial instruments through professional supply chain companies for hedging against raw material price increase risks.

Quality and Compliance Traps

The final category of traps relates to quality and compliance, including lack of quality control systems, products not meeting regulations, and financial security issues. These problems are often “invisible costs”—once they explode, they render all your previous investments worthless.

Building Standardized Quality Control Systems

Ensuring quality consistency from samples to bulk orders requires standardized quality control processes. I implemented a “three-inspection method” in ASG’s quality control team:

- 1. Factory self-inspection: Factories conduct initial inspections according to your standards, checking main quality issues during production

- 2. Warehouse sampling: After bulk goods enter warehouse, extract portions for second checks, ensuring batch consistency and confirming packaging, accessories, etc.

- 3. Pre-shipment final inspection: Re-check appearance, function, and packaging status before shipping—handle problems immediately when found

This method nips problems in the bud. An American seller following our approach saw return rates drop from 8% to 0.9%, with store ratings improving accordingly.

Importance of Product Compliance

Different countries and regions have different regulatory requirements for products. Electronics need CE, FCC, RoHS certifications; food and cosmetics need FDA or EU certifications; even children’s toys have EN71 standards. Without compliance certificates or test reports, products face delisting at minimum, fines at worst.

The biggest compliance misconception is “if others can sell it, so can I.” Actually, platform compliance checks are random—sometimes many sellers violate rules, but once platforms catch you, you bear full responsibility. Therefore:

- • Understand target market regulations in advance: Different markets have different requirements—consult professionals or review relevant documents early, listing necessary certificates and tests

- • Work with qualified factories: Some factories already have relevant certifications and can provide ready certificates, greatly shortening approval times

- • Save complete documentation: Including certification reports, test reports, compliance markings, etc., for platform or customs inspections

- • Emphasize continuous compliance: Regulations update over time—regularly monitor latest policies and upgrade promptly

Protecting Financial Security and Financial Management

Financial security isn’t just about preventing supplier flight—it includes cash flow management, exchange rate risk control, etc. Dropshipping must deal with various currency conversions and international settlements—without attention, exchange rate differences easily eat profits, or funds get frozen/returned.

Some practical suggestions:

- • Use third-party escrow or payment protection: Platform or bank escrow services release funds only after goods pass inspection, greatly reducing risks

- • Staged payments and acceptance: Pay in stages according to production progress instead of paying everything at once, ensuring each phase stays controllable

- • Avoid exchange rate traps: Use hedging or derivative tools to reduce exchange rate fluctuation impacts on profits; plan payment timing in advance to avoid unfavorable rate movements

- • Maintain healthy cash flow: Dropshipping businesses have longer cash flow cycles—plan finances well, reserve sufficient working capital for emergencies

Advanced Pitfalls and Avoidance Guide

After deeply understanding core supply chain elements, you might ask: what other pitfalls easily trap newcomers and advanced sellers? Based on handling hundreds of cases, here are common misconceptions and corresponding avoidance strategies.

Common Misconception Analysis

- 1. Over-relying on single platforms or channels: Many sellers put all sales on one platform like TikTok or Amazon. Once platform policies change, algorithms adjust, or store bans occur, your business instantly stops. Recommendation: Multi-channel deployment across Shopify, Amazon, TikTok, eBay, etc., using integrated inventory and order management systems for data synchronization.

- 2. Ignoring data analysis: Many rely on gut feelings for product selection and advertising experience, overlooking data-driven importance. Recommendation: Learn to use keyword tools, trend analysis tools, and advertising backend data for product selection decisions and timely strategy adjustments. Data doesn’t lie—it helps discover potential bestsellers or cut losses promptly.

- 3. Only focusing on price while ignoring value: Over-obsessing with low-cost sourcing often sacrifices quality and customer experience. Recommendation: Consider supplier delivery speed, quality stability, after-sales support comprehensively—better to pay slightly more for overall experience protection. Remember, cost-effectiveness isn’t just about price—it’s about long-term value.

- 4. Underestimating after-sales and customer service importance: Some sellers see after-sales as troublesome, avoiding when possible, but this is key to retaining customers. Recommendation: Establish 7×24 customer service mechanisms, respond quickly to customer issues, handle refunds/exchanges promptly, making customers feel valued. Good after-sales brings repeat sales and word-of-mouth promotion.

Practical Tools and Resource Recommendations

To improve supply chain efficiency and overall operational capabilities, I’ve summarized commonly used and effective tools and resources suitable for sellers of different scales:

- • ERP systems: For multi-platform orders, use professional ERPs like Shopify’s built-in system or mature dropshipping ERPs (like Shoplazza, Dianxiaomi, etc.), achieving real-time inventory sync, automatic shipping label printing, financial reconciliation. This reduces manual errors while improving processing efficiency

- • Order automation tools: For high-volume sellers, use automation plugins or software for batch order processing like automatic shipping marking, bulk tracking number uploads. This lets you focus on product selection and marketing instead of manual operations

- • Supply chain service providers: Third-party supply chain companies like ASG provide one-stop services from product selection, procurement, warehousing, logistics, after-sales to brand packaging. Especially for newcomer sellers or small teams, this model saves manpower and trial-and-error costs. Membership programs typically include dedicated customer service, data analysis reports, custom packaging services

- • Keyword and trend analysis tools: Like Google Trends, Jungle Scout, Alibaba Index, etc., for judging product search heat and competition levels. Data-driven product selection effectively improves success rates

- • Learning and community resources: Join dropshipping exchange groups, subscribe to professional blogs or YouTube channels (like Brian Dean’s SEO channel), getting timely industry updates and practical tips through community mutual aid and experience sharing

Future Trends and Advanced Strategies

The dropshipping industry develops rapidly—understanding future trends lets you prepare early, even ahead of competitors. Below are trends I’ve observed and corresponding advanced strategies:

Future Development Trends

- 1. Supply chain digitization and intelligence: More companies use AI and data analytics to predict demand, optimize restocking, formulate pricing strategies. Recommend sellers focus on digital tools like intelligent inventory prediction systems, AI-driven advertising tools—they can dramatically improve operational efficiency.

- 2. Sustainable and eco-friendly packaging: As consumer environmental awareness rises, biodegradable packaging and carbon-neutral logistics become new competitive points. If your brand does environmental packaging well, it not only improves customer goodwill but easier platform approval. Start with simplified packaging, recycled materials, carbon offset programs.

- 3. Multi-channel integration and brand operations: Future dropshipping sellers won’t just “distribute goods”—they’ll build brands. Shape brand image through social media operations, content marketing, KOL cooperation, combined with independent websites or mini-programs for closed-loop consumption chains. Capable sellers can try offline experience stores or pop-up events for user stickiness.

- 4. Membership and community economy: More sellers try membership programs, improving customer loyalty through exclusive discounts, dedicated service, early access benefits. Community operation is also trending—many brands interact with customers through Facebook groups or Discord servers, sharing usage experiences and new product previews, forming strong user communities.

From personal experience, sellers who actively embrace new trends and continuously upgrade supply chain and brand capabilities are more likely to stand out in competitive markets. Don’t fear trying, don’t stay in comfort zones: act early, get dividends early.

Conclusion: Supply Chain Is the Foundation of Dropshipping Success

Reviewing this article, we started with supply chain’s nine hidden killers, deeply analyzing logistics, costs, customer experience, supplier management, compliance, and financial security. Through my practical experience and cases, you should understand: successful dropshipping doesn’t just rely on advertising and bestsellers—it depends on stable, efficient supply chain systems. Master delivery speed, control costs, provide quality experiences, handle compliance and risk management well, and your profits can grow sustainably.

The biggest benefit of mastering this knowledge is that you’re no longer passively reactive—you proactively prevent and optimize. Whether you’re a dropshipping newcomer or mid-level seller wanting to break through bottlenecks, these methods help you build more solid business foundations.

Now it’s time to act! Return to your backend, check if logistics channels are fast enough; review your supplier list, consider adding more backups; re-evaluate packaging and after-sales processes; list and complete compliance certificates one by one. Put these suggestions into practice and you’ll see clear improvements.

Finally, thanks for patiently reading this long article. Believe that with dedicated management and continuous learning, you absolutely have the ability to shine in the dropshipping arena. Wishing you business prosperity and all the best!