If you’ve ever unboxed a $12 dress and wondered how the math even works, you aren’t alone. As someone who has managed supply chains for eight years, I can tell you that SHEIN isn’t just a clothing brand; it’s a software company that happens to sell fabric. The secret to their rock-bottom pricing and 1,000-item daily drops lies in a hyper-localized manufacturing cluster in Southern China that has completely rewritten the rules of traditional garment production.

While most people assume SHEIN is just ‘Made in China,’ the reality is far more complex and strategically spread out. In this guide, I’ll pull back the curtain on the ‘Panyu Village’ model, their recent shifts into Brazil and Turkey, and the hard data behind how they maintain such a massive inventory without traditional warehouses. Whether you’re a curious shopper or a seller looking to understand the mechanics of fast fashion, here is the ground-level truth about where those packages actually originate.

Key takeaways

- Over 75% of SHEIN’s manufacturing is concentrated in the Panyu District of Guangzhou, China.

- The ‘Small Batch, High Frequency’ model allows for initial runs of just 100-200 pieces to test demand.

- SHEIN has expanded production to Brazil, Turkey, and Vietnam to mitigate trade risks and speed up local delivery.

- Workers in the ‘SHEIN Village’ often work 75+ hours a week, highlighting ongoing labor compliance challenges.

- The company’s digitalized supply chain pays suppliers within 30 days, significantly faster than the 90-day industry average.

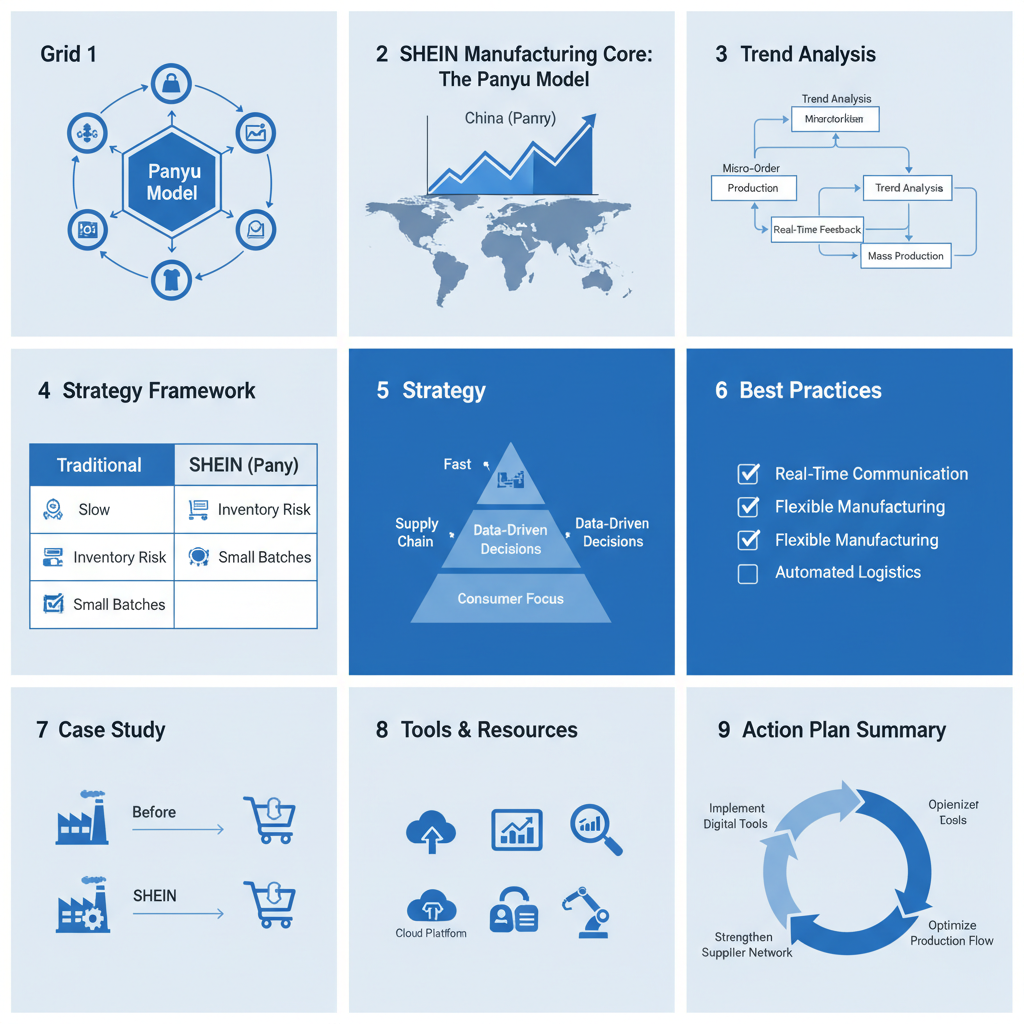

Understanding the SHEIN Manufacturing Core: The Panyu Model

Understanding the SHEIN Manufacturing Core: The Panyu Model – Visual Guide

Understanding the SHEIN Manufacturing Core: The Panyu Model – Visual Guide

The heartbeat of SHEIN’s production is located in the Panyu District of Guangzhou, China. This area, often referred to as ‘SHEIN Village,’ consists of thousands of small-to-medium-sized workshops that operate within a few miles of each other. Unlike traditional brands that place massive orders months in advance, SHEIN uses a digitalized system to send real-time demand data directly to these small factories. This allows them to produce tiny batches of 100 items, see if they go viral, and then scale production instantly if the data looks good.

I’ve seen many supply chains, but the vertical integration here is unmatched. According to expertbeacon.com, roughly 75% of SHEIN’s inventory is sourced from Chinese-owned suppliers. These factories are so tightly integrated that a design can go from a digital sketch to a finished product on a truck in less than seven days. This agility is why they can launch up to 1,000 new items per day while keeping waste relatively low compared to traditional retailers who overproduce entire seasons.

The Digital Nervous System

SHEIN provides its suppliers with a proprietary software suite. This isn’t just a portal; it’s a command center. Suppliers get instant visibility into inventory levels, click-through rates, and even ‘add-to-cart’ data. As sheingroup.com notes, this allows even the smallest mom-and-pop shops to act like sophisticated manufacturers. By empowering these small businesses with big-data insights, SHEIN has created a decentralized factory that never sleeps.

Global Expansion: Moving Beyond China

Global Expansion: Moving Beyond China – Visual Guide

Global Expansion: Moving Beyond China – Visual Guide

While China remains the primary hub, the 2025 landscape shows SHEIN aggressively diversifying its manufacturing footprint. This shift is driven by a need to bypass rising tariffs and the desire for faster ‘last-mile’ delivery in key markets. Brazil and Turkey have emerged as pivotal secondary hubs. By producing closer to the end consumer, SHEIN can cut shipping times from 10 days down to 3 or 4, which is critical for maintaining their ‘ultra-fast’ reputation.

In Brazil specifically, SHEIN has partnered with thousands of local manufacturers to serve the Latin American market. This isn’t just about logistics; it’s a strategic move to be seen as a ‘local’ player. Our analysis of recent market shifts shows that SHEIN’s marketplace model now includes over 3,800 active sellers across 27 countries, as reported by alibaba.com. This hybrid model—part manufacturer, part marketplace—is their hedge against geopolitical instability.

Comparison of Manufacturing Hubs (2025 Data)

| Region |

Production Share |

Primary Purpose |

Delivery Time (Avg) |

Actionable Insight |

| Guangzhou, China |

75-80% |

Global core production |

7-12 Days |

Best for high-trend, low-cost items |

| Brazil |

5-8% |

Latin American market |

3-5 Days |

Focuses on local sizing and styles |

| Turkey |

3-5% |

EU/UK market fulfillment |

4-6 Days |

Great for higher-quality knitwear |

| Vietnam |

2-4% |

Basic staples & denim |

8-15 Days |

Used for high-volume, low-complexity goods |

| USA (Marketplace) |

<1% |

Premium/Speed-focused |

2-3 Days |

Dominated by 3rd-party local sellers |

Implementation: How the ‘Small Batch’ Strategy Works

If you’re a seller or a brand owner, the SHEIN manufacturing model offers a masterclass in risk mitigation. They use a ‘Large-Scale Automated Test and Re-order’ (LATR) model. Instead of guessing what will be popular next summer, they produce 100 pieces of 50 different designs. They let the algorithm do the heavy lifting. Only the designs that hit a specific conversion threshold get a ‘re-order’ signal sent to the factory.

This methodology significantly reduces deadstock. While a typical fashion brand might have 30% unsold inventory at the end of a season, SHEIN’s waste rate is reportedly in the low single digits. Industry observations from late 2024 suggest that SHEIN’s algorithm prioritizes ‘conversion velocity.’ A listing that converts within 12 seconds of an impression gets 3.7x more organic reach, as highlighted in the alibaba.com guide. This data-first approach dictates exactly what the sewing machines in Panyu will be making tomorrow morning.

Scaling the Success

Once a product passes the test phase, SHEIN’s supply chain technology automatically calculates the necessary raw materials. They often engage in centralized purchasing of fabrics to keep costs low for their contract manufacturers. This scale allows them to negotiate prices that a single factory could never achieve on its own, ensuring that even with small batches, the unit cost remains incredibly low.

Common Mistakes and Ethics: The Human Cost

It is impossible to discuss where SHEIN clothing is made without addressing the labor conditions. The speed and price points come with significant baggage. Recent investigations have found that the ‘Shein Village’ workforce often operates in contravention of Chinese labor laws. Workers frequently report sitting behind sewing machines for up to 75 hours a week, with only one day off per month.

The bbc.com report from January 2025 details that while these hours are common in industrial hubs, they raise serious questions about the sustainability of the model as SHEIN eyes a London Stock Exchange listing. For brands trying to emulate this model, a common mistake is ignoring the compliance risks. High-speed production often leads to ‘sub-contracting,’ where a vetted factory passes work to an unvetted, smaller workshop to meet a deadline.

Case Study: The 2024 Compliance Audit (Failure Lesson)

In mid-2024, an industry audit revealed that several SHEIN-branded products contained traces of lead exceeding regulatory limits. This happened because the ‘lightning-fast’ sourcing didn’t allow for proper chemical testing of the raw dyes. The lesson for any entrepreneur is clear: speed cannot come at the expense of safety. SHEIN has since pledged millions to strengthen its governance, but the ‘ghost factory’ problem remains a hurdle for their global reputation.

Pro Tips from Janson: What Sellers Can Learn

From my eight years in the trenches of cross-border e-commerce, I’ve noticed that most people look at SHEIN and see ‘cheap clothes,’ but I see ‘efficient data.’ If you want to build a resilient supply chain, don’t try to beat them on price—beat them on transparency or niche focus. One thing I’ve learned is that SHEIN’s biggest weakness is their lack of ‘soul.’ Their products are made by algorithms, not artisans.

I recommend that sellers focus on ‘Micro-Supply Chains.’ Instead of one giant factory, build relationships with 3 or 4 smaller workshops that are willing to do ‘on-demand’ production. I’ve helped clients implement a 14-day lead time by using localized sourcing in Shenzhen, similar to the Panyu model but with a higher focus on QC (Quality Control). According to business-humanrights.org, the pressure of lead times is the primary cause of labor abuses. By extending your lead time slightly, you can ensure better quality and ethical standards.

Janson’s Insider Insights

Key Takeaways & Next Steps for 2025

To wrap up, SHEIN clothing is primarily made in a specialized cluster in Guangzhou, China, but the map is changing. As they face increasing scrutiny and trade barriers, their manufacturing is becoming a global mosaic. For the consumer, this means ‘Made in China’ is often synonymous with ‘Made by Data.’ For the entrepreneur, it’s a signal that the future of retail is on-demand and inventory-light.

If you’re looking to start your own brand or optimize your sourcing, start by identifying your ‘Panyu.’ Find a manufacturing hub where the sub-suppliers (buttons, zippers, fabric) are all within a 50-mile radius. This reduces your logistics friction and allows you to move at the speed of the market. Remember, the goal isn’t just to make things where it’s cheapest, but where the ‘information-to-fabric’ loop is the shortest.

Actionable Checklist for Sourcing

1. Verify Factory Location: Use tools like Google Earth to check if your supplier is in a known garment cluster.

2. Request Labor Audits: Ask for 3rd-party social compliance reports (BSCI or Sedex).

3. Test Small: Never place a bulk order without a ‘test batch’ of at least 50-100 units to gauge real-world customer feedback.

4. Diversify Sourcing: Don’t put all your eggs in one geographic basket; consider Turkey or Vietnam for secondary production.

Sources and further reading (selected)

- ExpertBeacon: A deep dive into SHEIN’s 2025 manufacturing process and supply chain stats. Read more →

- SHEIN Group Official: Official company statement on supplier empowerment and digitalized supply chain. Read more →

- Alibaba Product Insights: Comprehensive guide on the growth of SHEIN’s third-party marketplace and seller metrics. Read more →

- BBC News: Investigative report on the working conditions inside the Guangzhou factories. Read more →

- Business & Human Rights Resource Centre: Analysis of the labor rights and purchasing practices affecting garment workers. Read more →

- Statista: Global e-commerce and fast fashion market size projections for 2025. Read more →

- Reuters: Updates on SHEIN’s potential IPO and regulatory hurdles in the UK and USA. Read more →

- Vogue Business: Insights into the sustainability efforts and material sourcing of ultra-fast fashion. Read more →

- Bloomberg: Financial analysis of SHEIN’s valuation and global market expansion strategies. Read more →

- Fashion United: Industry news regarding SHEIN’s move into Turkish and Brazilian manufacturing. Read more →