If you’ve ever pulled on a pair of $100+ Align leggings and wondered how they achieved that ‘buttery-soft’ feel, you aren’t just paying for a logo—you’re paying for one of the most sophisticated textile supply chains on the planet. As the CEO of ASG, I’ve spent years analyzing how top-tier brands like Lululemon balance premium quality with global scale. The truth is that Lululemon isn’t just ‘made in China’; it is the result of a complex network spanning 19 countries and over 130 specialized facilities.

In this guide, we will peel back the label to show you exactly where your gear comes from, why specific fabrics like Luon are sourced from Taiwan, and how the brand maintains its high ethical standards while operating across borders. Whether you are a curious consumer or an e-commerce entrepreneur looking to emulate their success, understanding this manufacturing blueprint is essential for appreciating the value behind the price tag.

Key takeaways

- Vietnam is the primary hub, accounting for over 32% of final product manufacturing.

- China remains a critical secondary partner, handling roughly 16% of production.

- Taiwan is the secret weapon for innovation, producing the trademarked Luon fabric.

- The brand utilizes a ‘Top Tier’ system with 113 facilities focused on final assembly.

- Lululemon maintains a small but strategic manufacturing presence in the United States.

Understanding the Lululemon Manufacturing Core

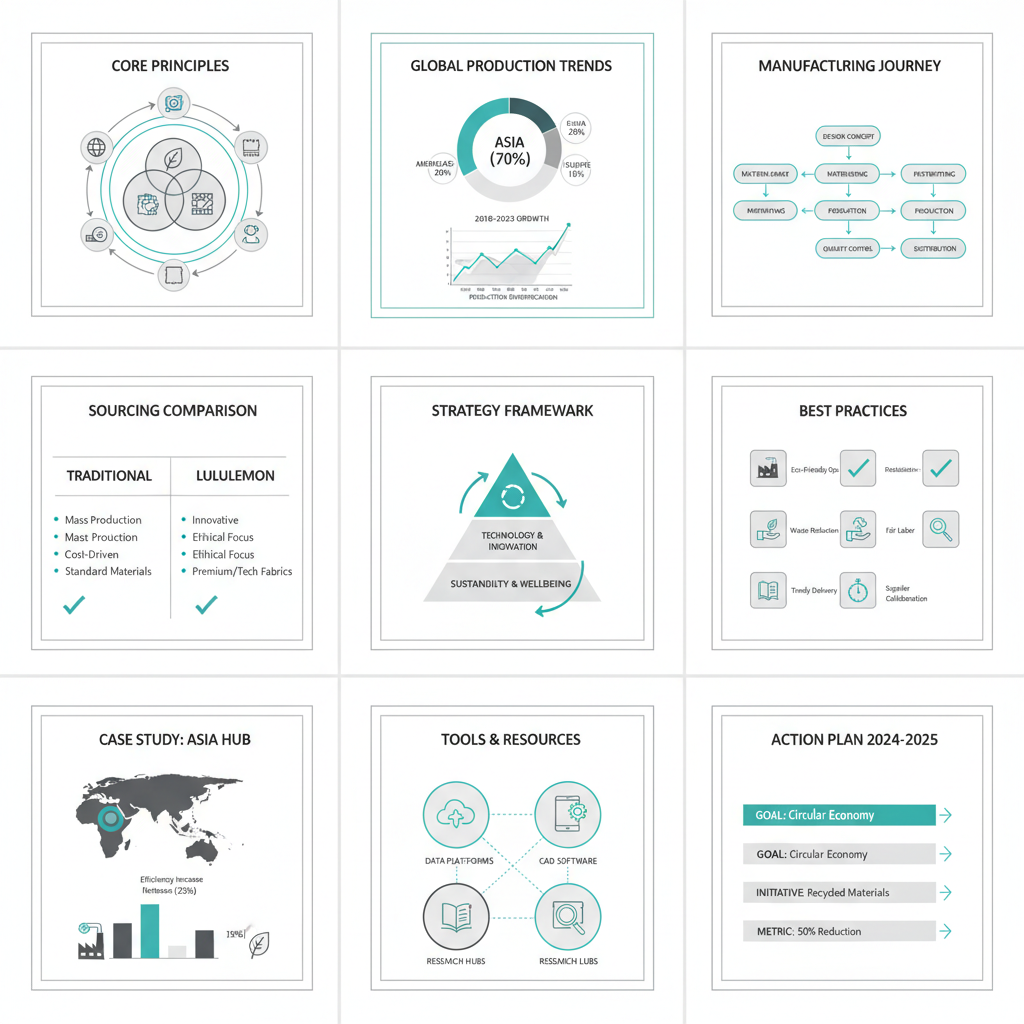

Understanding the Lululemon Manufacturing Core – Visual Guide

Understanding the Lululemon Manufacturing Core – Visual Guide

To understand where Lululemon is made, you must first understand their ‘Tier’ system. Unlike fast-fashion brands that jump between the lowest bidders, Lululemon builds long-term partnerships with specialized factories. According to runnersathletics.com, the company currently relies on 138 different facilities across 19 countries. Of these, 113 are classified as ‘Top Tier,’ meaning they are responsible for the final assembly of the garments you see in stores.

This global footprint is not accidental. It is a strategic diversification designed to mitigate risk. If a disruption occurs in one region, the brand can shift production to another without sacrificing the technical quality their customers expect. As reported by allamericanmade.com, while the brand is Canadian-owned, the vast majority of its production occurs in Asia to leverage specialized technical apparel expertise that is difficult to find elsewhere.

The Hierarchy of Production

1. Raw Material Suppliers: These factories create the yarns and fabrics (like Luon or Nulu).

2. Subcontractors: Specialized shops for printing, washing, or pleating.

3. Finished Goods Suppliers: The ‘Top Tier’ factories that cut and sew the final product.

By controlling each stage, Lululemon ensures that a pair of leggings made in Vietnam feels identical to one made in Sri Lanka. This consistency is what allows them to maintain premium pricing in a crowded market.

Why the Supply Chain Matters in 2026

Why the Supply Chain Matters in 2026 – Visual Guide

Why the Supply Chain Matters in 2026 – Visual Guide

In 2026, transparency is the new currency of luxury. Modern consumers aren’t just buying a product; they are buying the ethics of the supply chain. Lululemon has stayed ahead of this trend by publishing detailed supplier lists, which allamericanmade.com notes is a key part of their corporate responsibility. This level of openness builds trust, especially as competitors face scrutiny over labor practices.

Furthermore, the shift toward ‘near-shoring’ and diversification has become a major trend. While Vietnam remains the powerhouse, the brand has expanded its footprint in places like Turkey and Portugal to better serve the European market. Data from runnersathletics.com suggests that this geographic spread helps the brand maintain a 6-10 day shipping window for many global regions, a feat that is nearly impossible with a single-source strategy.

| Country |

Percentage of Top Tier Facilities |

Primary Focus |

| Vietnam |

32.74% |

Apparel & Accessories |

| China |

15.93% |

High-Volume Apparel |

| Sri Lanka |

10.62% |

Technical Intimates |

| Cambodia |

8.85% |

Outerwear & Bags |

| USA |

3.54% |

Specialized Apparel |

This data highlights that while they are a global brand, their heart for production beats strongest in Southeast Asia, where the infrastructure for technical knits is most advanced.

Implementation Strategies: How Lululemon Manages Quality

Lululemon doesn’t just send a tech pack to a factory and hope for the best. They implement a ‘boots on the ground’ quality control strategy. My experience at ASG has shown that the only way to maintain a <1% defect rate at this scale is through rigorous on-site inspections. According to runnersathletics.com, Lululemon defines their top 113 facilities as partners in ‘Final product manufacturing,’ which involves strict adherence to proprietary sewing techniques.

One of the most impressive parts of their implementation is the fabric sourcing. While many think the fabric is made in the same place as the garment, that is rarely true. Taiwan, for instance, only accounts for about 4% of final assembly but is the primary source for the trademarked Luon fabric. This separation of fabric creation and garment assembly allows Lululemon to guard their intellectual property (the fabric recipes) while utilizing the best labor markets for assembly.

Actionable Steps for Quality Control

This multi-layered approach is why a Lululemon legging can withstand hundreds of wash cycles without losing its shape, a core value proposition that justifies the $100+ price tag.

Common Mistakes to Avoid in Global Sourcing

Many entrepreneurs try to copy Lululemon’s model but fail because they make the mistake of over-centralizing. Relying on a single factory in China or Vietnam is a recipe for disaster if a local lockdown or shipping crisis occurs. As allamericanmade.com points out, Lululemon avoids this by spreading production across 19 countries, ensuring that no single geopolitical event can take down the entire brand.

Another common failure is neglecting the ‘Tier 2’ and ‘Tier 3’ suppliers. A brand might find a great sewing factory (Tier 1), but if that factory buys cheap zippers or low-quality thread from an unvetted Tier 2 supplier, the final product will fail. Lululemon’s success comes from the fact that they vet the entire chain. According to runnersathletics.com, they even track subcontractors involved in ‘washing and printing’ to ensure environmental standards are met.

Lessons from Real Failures

Pro Tips from Janson: Insider Insights on Technical Apparel

As CEO of ASG, I often tell my clients: ‘Don’t look for the cheapest factory; look for the one with the best machinery.’ Lululemon’s secret isn’t just cheap labor in Vietnam; it’s the specialized flatlock stitching machines and heat-bonding equipment found in their partner facilities. If you want to build a premium brand, you need to find factories that invest in the same technology used by Lululemon’s ‘Top Tier’ partners in Sri Lanka and Vietnam.

Another pro tip is to leverage Taiwan for R&D. While Vietnam is great for assembly, Taiwan is the world leader in functional textiles. As mentioned by runnersathletics.com, Taiwan is where the magic of Luon happens. If you are developing a new product, spend your R&D budget in Taiwan or Japan, then move to Vietnam or Indonesia for mass production to balance costs.

Janson’s Sourcing Checklist

By following these ‘insider’ rules, you can achieve a level of product quality that rivals the biggest names in the industry.

Key Takeaways & Next Steps

Understanding where Lululemon is made reveals a brand that is as much a logistics company as it is a fashion house. By diversifying across 19 countries and focusing heavily on Vietnam (32%) and China (16%), they have built a resilient, high-quality machine. As allamericanmade.com highlights, even though they have a small footprint in the USA, their heart remains in the technical hubs of Asia.

For the consumer, the ‘Made in Vietnam’ tag is a sign of high-tech manufacturing, not low-quality labor. For the entrepreneur, it is a blueprint for how to scale a premium brand using a tiered supplier system. According to the supplier data from runnersathletics.com, the brand continues to expand into new markets like Turkey and Mexico, proving that the search for the perfect manufacturing balance never ends.

Your Action Plan

1. Check Your Labels: Look for where your favorite pieces are made—you’ll likely see the diversity mentioned here.

2. Research Fabrics: Understand the difference between the assembly country and the fabric origin.

3. Follow the Data: Keep an eye on Lululemon’s annual ‘Sustainability and Social Impact’ reports for the most updated supplier lists.

Lululemon’s journey from a single Vancouver studio to a global powerhouse was paved by this incredible supply chain. By understanding it, you understand the future of retail.

Sources and further reading (selected)

- Runners Athletics – Global Manufacturing: Comprehensive breakdown of Lululemon’s 19 manufacturing countries and facility tiers. Read more →

- All American Made – Lululemon Guide: An analysis of Lululemon’s US manufacturing presence and overall sourcing strategy. Read more →

- Runners Athletics – UK Edition: Regional insights into Lululemon’s manufacturing for the European market. Read more →

- Runners Athletics – Canada Edition: Detailed look at the Canadian brand’s global supplier network. Read more →

- Runners Athletics – AU Edition: Information on Lululemon’s manufacturing facilities and fabric sourcing in Taiwan. Read more →

- Lululemon Supplier List (Official PDF): The primary source document for all Lululemon vendors and subcontractors. Read more →

- Lululemon Global Code of Conduct: The ethical guidelines Lululemon requires all its global manufacturers to follow. Read more →

- Statista – Lululemon Revenue Data: Financial context showing the scale of production required by the brand. Read more →

- Taiwantrade – Textile Innovation: Context on Taiwan’s role as a leader in functional and technical textiles. Read more →

- Business of Fashion – Supply Chain Transparency: Industry analysis on why transparency in manufacturing is critical for premium brands. Read more →