If you’ve ever pulled on a pair of Align leggings and wondered how that ‘naked sensation’ came to be, you aren’t alone. As someone who has managed supply chains for years at ASG, I can tell you that Lululemon’s manufacturing is a masterclass in global logistics. While the brand is proudly Canadian, the tag on your favorite yoga pants tells a much more international story.

In this guide, we’re going behind the scenes to uncover the 19+ countries that power this athleisure giant. We’ll look at why Vietnam has become their primary hub, the specific role China plays in their production, and the secret technology coming out of Taiwan that makes their fabrics impossible to replicate. Whether you’re a curious shopper or a business owner looking to understand top-tier sourcing, here is the truth about where Lululemon is made.

Key takeaways

- Vietnam is Lululemon’s primary manufacturing hub, hosting over 32% of their top-tier facilities.

- China remains a critical secondary producer, handling roughly 16% of final product manufacturing.

- Taiwan is the technological heart of the brand, producing the trademarked Luon fabric.

- Lululemon operates a ‘Top Tier’ system with 113 facilities focused on final assembly.

- The brand maintains a small manufacturing presence in the USA and Portugal for specialized lines.

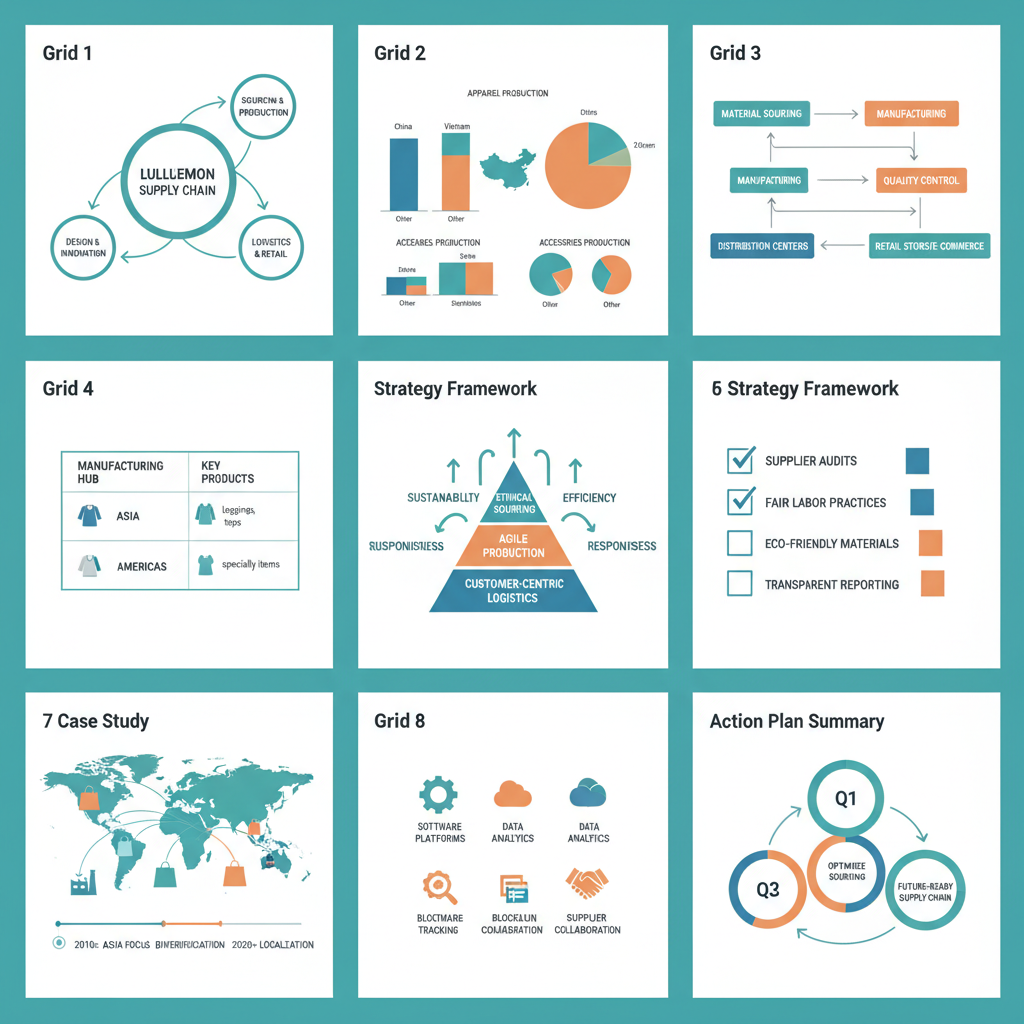

Understanding the Lululemon Supply Chain: Core Concepts

Understanding the Lululemon Supply Chain: Core Concepts – Visual Guide

Understanding the Lululemon Supply Chain: Core Concepts – Visual Guide

Lululemon does not own any of its manufacturing facilities. Instead, they operate through a sophisticated network of third-party vendors. This “asset-light” model allows them to scale rapidly while maintaining high quality. According to data from runnersathletics.com, the company relies on approximately 138 different facilities across 19 countries to bring their designs to life.

To maintain their premium status, Lululemon categorizes their partners. They define 113 of these as “Top Tier” facilities, which are solely responsible for final product manufacturing. This distinction is crucial because while raw materials might be sourced globally, the final stitching and quality control happen in these vetted locations. As noted by allamericanmade.com, this global strategy allows the brand to balance lower labor costs in Asia with high-tech fabric development in specialized regions.

The Tiered System Breakdown

| Facility Type |

Function |

Focus |

| Top Tier |

Final Assembly |

Finished leggings, hoodies, and bags |

| Subcontractor |

Specialized Processes |

Printing, washing, and laundry |

| Raw Material |

Fabric Production |

Luon, Nulu, and Everlux creation |

This structure ensures that even if a product is ‘Made in Vietnam,’ the technology inside the fabric might have originated in a high-tech lab in Taiwan or South Korea. This separation of fabric creation and garment assembly is what allows Lululemon to protect its intellectual property while leveraging global labor markets.

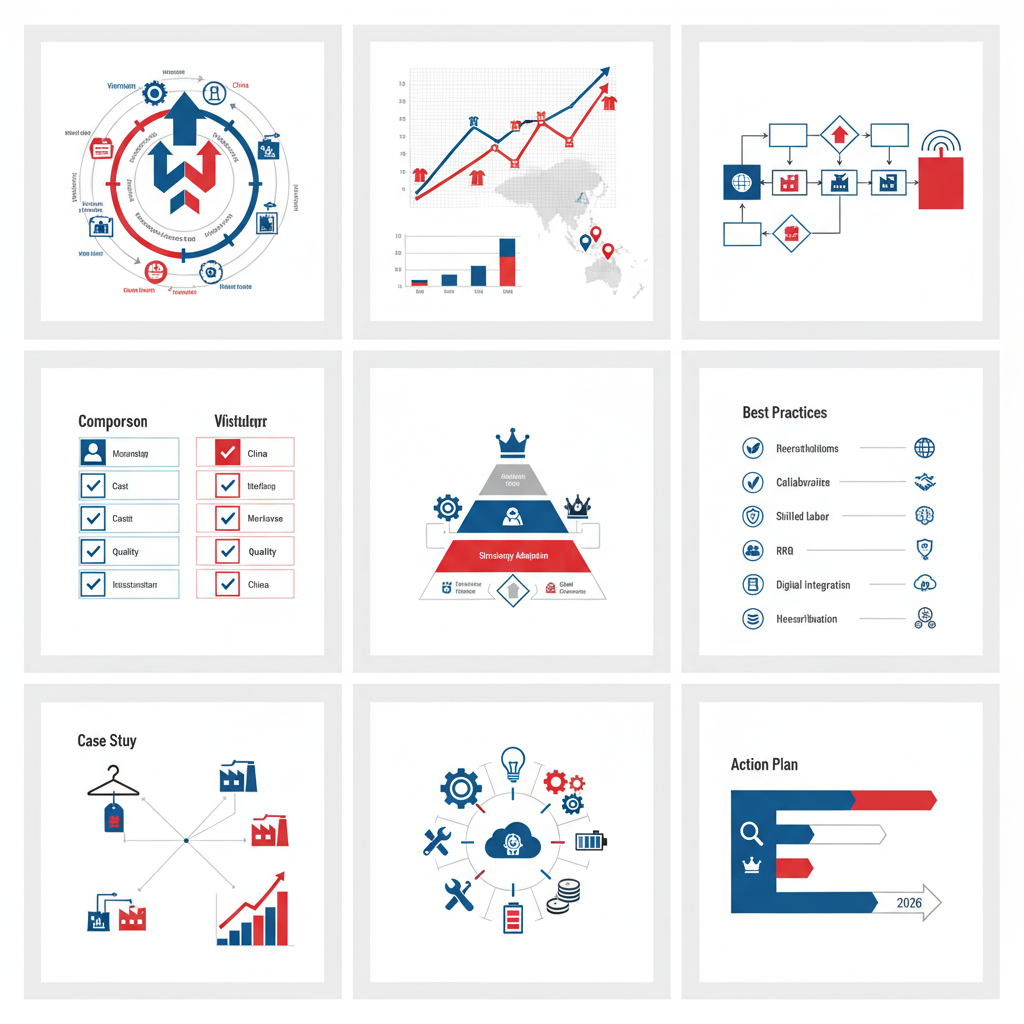

Why Vietnam and China Lead the Pack in 2026

Why Vietnam and China Lead the Pack in 2026 – Visual Guide

Why Vietnam and China Lead the Pack in 2026 – Visual Guide

Vietnam has solidified its position as the powerhouse of Lululemon’s production. Currently, about 32.74% of their top-tier factories are located in Vietnam. This shift toward Southeast Asia is a trend I’ve seen across the entire dropshipping and e-commerce industry. Vietnam offers a unique combination of skilled textile labor and favorable trade agreements that make it ideal for technical apparel.

China follows as the second-largest producer, accounting for roughly 15.93% of manufacturing facilities. According to runnersathletics.com, China remains indispensable despite rising labor costs because of its unparalleled infrastructure and speed. For complex items like outerwear or bags with intricate hardware, the Chinese manufacturing ecosystem is still the global gold standard.

However, it is a common misconception that Lululemon is ‘just another Chinese-made brand.’ Their footprint in China is actually shrinking as they diversify into countries like Sri Lanka (10.62%) and Cambodia (8.85%). This diversification is a strategic move to mitigate geopolitical risks and supply chain bottlenecks, a strategy we always recommend to our high-level clients at ASG.

Implementation Strategies: How Lululemon Sources Quality

Lululemon’s success isn’t just about where they make things, but how they manage the vendors. They utilize a ‘Vertical Retail’ model where they control the design and the fabric, but outsource the labor. If you are looking to replicate this level of quality in your own business, you must start with fabric ‘blueprints.’

For example, Lululemon’s ‘Luon’ fabric is a trademarked blend of 86% nylon and 14% Lycra. According to runnersathletics.com, the majority of this fabric technology comes from Taiwan. Even though Taiwan only hosts 4.42% of their final assembly factories, it is arguably the most important country in their supply chain because it holds the ‘secret sauce’ for their textiles.

Strategic Sourcing by Country

1. Vietnam: High-volume apparel and accessories.

2. Taiwan: High-tech raw material and fabric innovation.

3. Sri Lanka: Specialized technical knitting and bras.

4. USA/Canada: Small-batch ‘Lab’ collections and rapid prototyping.

By splitting the manufacturing this way, they ensure that the ‘brain’ of the product (the fabric) is made in a high-tech environment, while the ‘body’ (the assembly) is handled in cost-efficient regions. This is the exact strategy we use at ASG to help sellers scale without sacrificing the premium feel of their brand.

Common Mistakes to Avoid in Apparel Sourcing

One of the biggest mistakes I see new sellers make is assuming that ‘Made in China’ or ‘Made in Vietnam’ automatically means lower quality. Lululemon proves that location is secondary to the SOPs (Standard Operating Procedures) you provide to the factory. If you don’t have a boots-on-the-ground presence to audit these 113 facilities, quality will inevitably slip.

Another mistake is ignoring the ethical and environmental impact. Lululemon has faced scrutiny in the past, leading them to release detailed supplier lists. According to allamericanmade.com, the brand now publicly audits its subcontractors for printing and washing processes in countries like Peru and the Philippines to ensure compliance with global standards.

Failure to diversify is the third major pitfall. If Lululemon had stayed 100% in China, the 2020-2022 supply chain crisis would have crippled them. Instead, their presence in 19 different countries allowed them to pivot production when certain regions went into lockdown. For any brand reaching the $1M+ GMV mark, having a secondary manufacturing hub is no longer optional—it is a survival requirement.

Pro Tips from Janson: Insider Sourcing Insights

After years of working with 2,300+ factories, I can tell you that Lululemon’s choice of Taiwan for fabric is their smartest move. Most people look at the finished garment, but the money is in the yarn. If you want to build a premium brand, don’t just find a factory on 1688; find the fabric mill first.

Lululemon uses a ‘VMI’ (Vendor Managed Inventory) approach with their top-tier suppliers. This means the factories in Vietnam often hold raw fabric in anticipation of orders, reducing the lead time to just a few weeks. According to runnersathletics.com, this efficiency is why they can drop new ‘We Made Too Much’ items every Thursday like clockwork.

Also, pay attention to their ‘Finished Goods’ subcontractors. Lululemon uses specific factories in Sri Lanka and Peru just for ‘washing’ and ‘printing.’ This tells you that the ‘feel’ of the fabric often happens after it’s sewn. If your products feel rough, it might not be the fabric—it might be the post-production wash. At ASG, we often help clients find these specialized subcontractors to give their products that ‘buttery soft’ finish.

Key Takeaways & Next Steps for Your Brand

Lululemon is a truly global brand, with its roots in Canada and its hands in 19 different countries. While Vietnam and China handle the bulk of the sewing, the brand’s soul lies in the technical fabrics developed in Taiwan. This diversified approach is the blueprint for any modern, high-growth e-commerce business.

If you’re ready to start your own journey in the athleisure space, remember that transparency is your best friend. As allamericanmade.com highlights, modern consumers care as much about where and how a product is made as they do about the logo. Use Lululemon’s supplier list as a benchmark for what a professional supply chain should look like.

—

Final Manufacturing Distribution (Top Tier)

| Country |

Percentage (%) |

Key Role |

| Vietnam |

32.74% |

High-Volume Assembly |

| China |

15.93% |

Complex Construction |

| Sri Lanka |

10.62% |

Technical Intimates |

| Taiwan |

4.42% |

Fabric Innovation |

| USA |

3.54% |

Small Batch/Specialty |

Ready to find your own ‘Top Tier’ factory? At ASG, we bridge the gap between you and the world’s best manufacturing hubs. Let’s build your brand with the same precision Lululemon uses.

Sources and further reading (selected)

- runnersathletics.com (CA): Comprehensive breakdown of Lululemon’s 19 manufacturing countries and facility tiers. Read more →

- allamericanmade.com: Detailed analysis of Lululemon’s supply chain, including US-based manufacturing and ethical sourcing. Read more →

- runnersathletics.com (General): Exploration of the trademarked Luon fabric and its origins in Taiwan. Read more →

- runnersathletics.com (UK): Data on the 138 facilities Lululemon uses globally for final product manufacturing. Read more →

- runnersathletics.com (AU): Insight into the global manufacturing strategy required to meet stylish and functional clothing demands. Read more →

- Lululemon Annual Report: Official financial and operational data regarding vendor relationships and geographic sourcing. Read more →

- Statista – Lululemon Revenue: Growth data showing the scale of production needed to support billions in annual revenue. Read more →

- Supply Chain Dive: Industry news regarding Lululemon’s logistics and inventory management strategies. Read more →

- Fashion Revolution: Transparency indices evaluating brand disclosures about their factory locations. Read more →

- Business of Fashion: Analysis of the athleisure market and the competitive advantage of technical fabric sourcing. Read more →