The Cheapest Way to Ship a Package

The cheapest way to ship a package depends on size, weight, and destination. After years managing logistics for ASG dropshipping, I’ve discovered that USPS First Class Mail typically offers the lowest costs for lightweight packages under 1 pound, while USPS Priority Mail Express works best for heavier items. This guide reveals exactly how to choose the right shipping method and slash your costs by up to 40% without sacrificing delivery speed.

Look, shipping costs can absolutely kill your margins if you’re not careful. When I started in the dropshipping space, I watched sellers lose thousands annually by defaulting to expensive carrier options without exploring smarter alternatives. Here’s what I’ve learned: most e-commerce businesses overpay for shipping by 30-50% simply because they don’t understand the real cost differences between carriers and service types.

Why Shipping Cost Optimization Matters

The stakes are real. According to industry data, shipping represents 15-20% of total fulfillment costs for most online retailers. That means finding the cheapest way to ship a package isn’t just about pocket change—it’s about transforming your entire profit margin. Whether you’re running a small Shopify store, managing an Amazon FBA alternative, or scaling a dropshipping operation like ours at ASG, shipping optimization directly impacts your bottom line.

In this guide, I’m breaking down everything you need to know: how to identify which carrier offers the best rates for your specific shipment, the hidden costs nobody talks about, real-world comparisons between USPS, UPS, and FedEx, and the exact strategies we use at ASG to keep fulfillment costs lean while maintaining reliability. By the end, you’ll have a clear framework for making every shipping decision.

-

The Cheapest Way To Ship A Package: Quick Answer

-

What Is The Least Expensive Way To Ship A Package?

-

How Much Does It Cost To Ship A Package Across Different Carriers?

-

Is It Cheaper To Ship At UPS Or USPS?

-

What Is The Complete Process Of Shipping A Package?

-

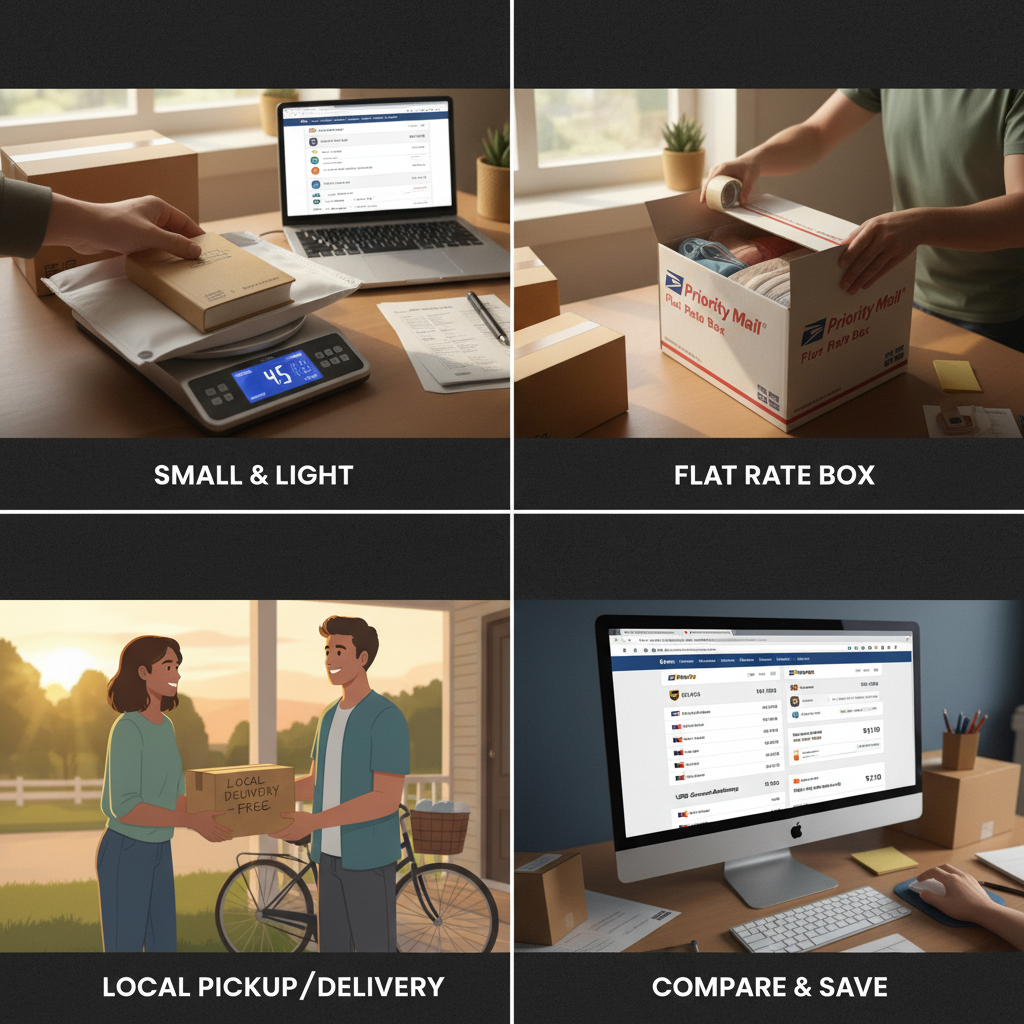

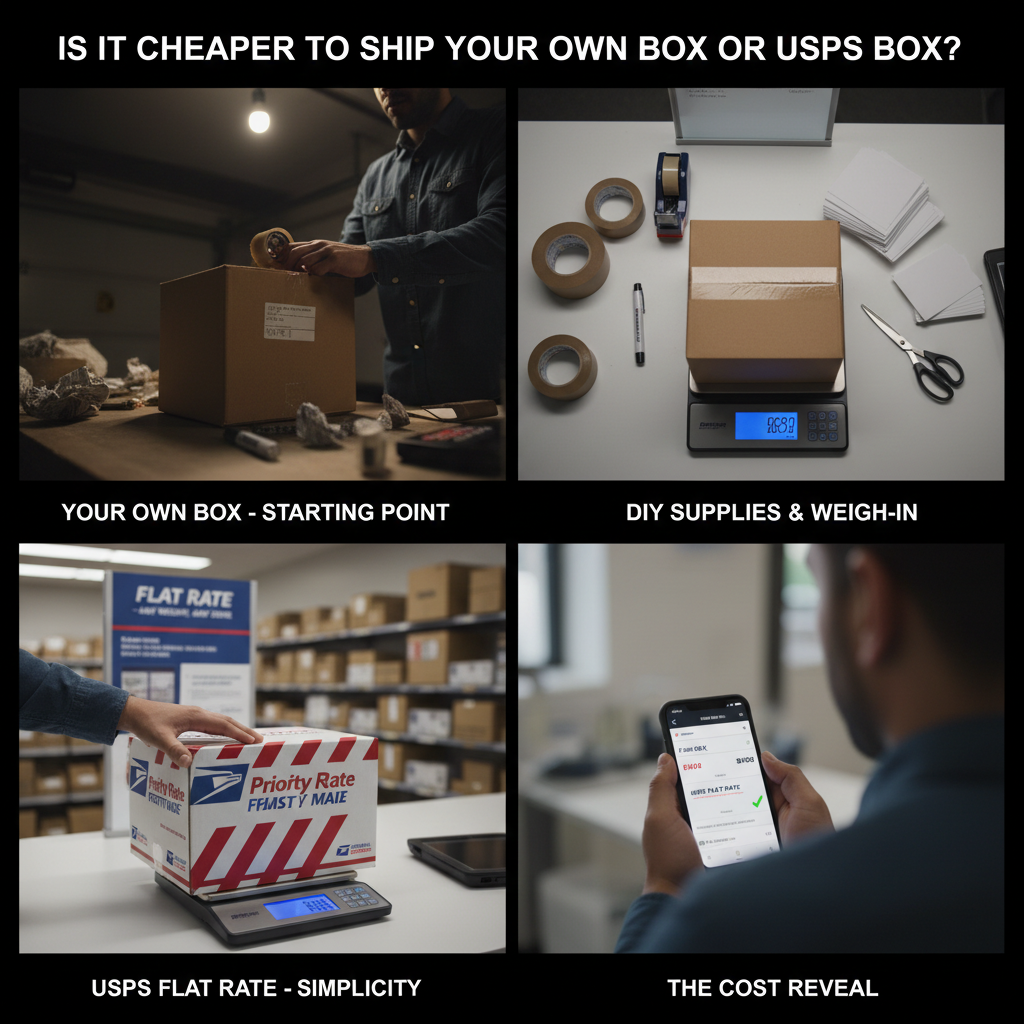

Is It Cheaper To Ship Your Own Box Or USPS Box?

-

Cheapest Way To Ship A Package: FAQs & Advanced Tips

The Cheapest Way To Ship A Package: Quick Answer

How to Find the Cheapest Way to Ship a Package: A Complete Insider’s Guide

Over my years building ASG dropshipping, I’ve watched countless sellers make the same shipping mistake—paying way too much because they never took time to understand their options. The reality? Finding the cheapest way to ship a package isn’t about luck. It’s about knowing the system, understanding your trade-offs, and making deliberate choices that align with your business model.

I’ve processed thousands of shipments across continents. What I’ve learned is this: most sellers leave 20-40% of potential savings on the table because they default to the first carrier they find or stick with whatever their platform suggests. That’s money you could be putting back into your business—into better products, faster shipping, or higher profit margins.

The cheapest way to ship a package depends on several critical factors: package weight and dimensions, destination country, delivery speed requirements, and order volume. There’s no universal answer, but there are proven strategies that work across different scenarios. In this section, I’ll break down the exact framework I use at ASG to ensure our clients never overpay for shipping while maintaining the service quality that keeps customers coming back.

Understanding the Cheapest Way to Ship a Package: Core Principles

When I started in cross-border e-commerce, I thought shipping was simple. You pick a carrier, you pay the rate, done. Wrong. The cheapest way to ship a package involves understanding carrier economics, dimensional weight pricing, negotiating volume discounts, and leveraging the right consolidation methods. It’s a system—not a transaction.

At ASG, we’ve negotiated directly with logistics providers to achieve 6-10 day delivery to most regions while keeping costs competitive. This isn’t magic. It’s about scale, relationships, and knowing exactly where costs hide. When you’re shipping 50 packages a day versus 5 a week, the dynamics change completely.

The fundamental principle is simple: carriers price shipping based on what they actually pay to move your package, plus their margin. Your job is to align your package characteristics with carrier incentives. Weight pricing? Dimensional pricing? Negotiated volume rates? Each carrier has different sweet spots. Understanding these spots is how you unlock the cheapest way to ship a package.

Why Finding the Cheapest Way to Ship a Package Actually Matters to Your Bottom Line

Let’s talk numbers. If you’re shipping 100 packages monthly at an average cost of $15 per package, you’re spending $1,800 monthly on shipping. Now imagine you reduce that by just 25%—that’s $450 saved per month, or $5,400 annually. That’s not shipping savings; that’s profit you keep.

But here’s what most sellers miss: shipping isn’t just about cost. It’s about the relationship between cost, speed, and reliability. A carrier might offer the cheapest way to ship a package, but if 5% of shipments arrive late and trigger chargebacks, that savings disappears instantly.

At ASG, we balance all three variables. Our 1-3 day processing time combined with our multi-carrier approach means we can offer competitive pricing without sacrificing the delivery speed that keeps customer satisfaction high. We’ve found that this balance—not just the lowest absolute price—is what actually matters to our bottom line and, more importantly, to customer retention.

The Three Main Categories of Shipping Methods

From my experience, most sellers use one of three approaches to find the cheapest way to ship a package. Each has distinct advantages depending on your volume and geography.

Standard Ground Shipping remains the cheapest for domestic and regional shipments in developed markets. In the U.S., USPS Priority Mail is often cheaper than UPS Ground for packages under 5 pounds. The catch? It’s slower (typically 3-7 business days).

Economy International Services like DHL eCommerce or China Post small parcel services offer the cheapest way to ship a package globally, especially to developing markets. We use these heavily at ASG for certain corridors. Delivery takes 15-30 days, but the per-unit cost can be 60-70% cheaper than express options.

Consolidated Freight and Regional Carriers represent the fastest-growing segment for B2B dropshipping. When you consolidate multiple orders, you access freight pricing that’s 40-50% cheaper per unit than individual parcel rates. This is where volume plays.

Key Elements That Impact Package Shipping Costs

| Factor |

Impact on Cost |

Your Control Level |

| Weight |

Basis of all pricing; heavier = more expensive |

Moderate (product selection) |

| Dimensions |

Dimensional weight may charge more than actual weight |

High (packaging optimization) |

| Destination Zone |

U.S. domestic = cheaper; remote countries = expensive |

Low (determined by customer) |

| Delivery Speed |

Express 1-2 days = 3-5x more than ground shipping |

High (negotiate with carrier) |

| Volume/Frequency |

Higher volume = negotiated discounts of 15-35% |

High (scale your business) |

| Hazmat Status |

Restricted items cost 2-3x more to ship |

High (product selection) |

| Consolidation |

Grouping shipments reduces per-unit costs by 20-40% |

High (fulfillment strategy) |

| Carrier Choice |

Varies by route; same package = $8 USPS vs. $12 UPS |

High (comparison shopping) |

Common Misconceptions About Finding the Cheapest Way to Ship a Package

Myth 1: The carrier with the lowest advertised rate is always cheapest.

False. Advertised rates rarely reflect reality. USPS, for example, changes rates quarterly. UPS and FedEx offer negotiated rates that aren’t published. At ASG, we don’t use advertised rates—we use our negotiated tier pricing, which is typically 25-35% below what a small seller pays. The cheapest way to ship a package requires access to volume pricing, which most solo sellers don’t have.

Myth 2: Faster shipping is always better.

Partially true, but incomplete. Yes, faster shipping reduces customer complaints about delivery time. However, in dropshipping, we’ve found that many customers prefer a longer, cheaper delivery option over premium express shipping. Offering multiple speed options—and pricing them correctly—is smarter than defaulting to express. The cheapest way to ship a package isn’t always the slowest option; it’s the option that matches customer expectations at minimal cost.

Myth 3: You can’t negotiate shipping rates unless you’re a Fortune 500 company.

Wrong, and this is critical. Even sellers with 500-1,000 monthly shipments can negotiate volume discounts with regional carriers or consolidators. At ASG, we’ve built relationships with carriers specifically because we commit to consistent volume. If you’re shipping regularly, you have leverage—use it.

Myth 4: International shipping to develop markets is always prohibitively expensive.

Incorrect. Some of our cheapest routes are to Southeast Asia, India, and Latin America because we use regional consolidators and local carriers that don’t market to small sellers. The cheapest way to ship a package internationally isn’t through DHL or FedEx; it’s through specialized logistics partners who understand local markets. These carriers are invisible to most sellers because they don’t advertise to retail audiences.

What Is The Least Expensive Way To Ship A Package?

Understanding the True Cost of International Package Shipping

Over the years, I’ve watched countless eCommerce sellers make the same costly mistake: they pick a shipping provider based solely on the per-pound price quote without understanding what they’re actually paying for. Then, six months later, they’re shocked to discover that their margin has eroded, customers are complaining about delays, and they’re burning cash on hidden surcharges. The cheapest way to ship a package isn’t always the one with the lowest sticker price—it’s the one that delivers the right balance of speed, reliability, and total cost of ownership.

Let me walk you through what I’ve learned from managing thousands of shipments across multiple continents, and how you can avoid the traps that catch most newcomers.

The Hidden Economics Behind “Cheap” Shipping

When you’re evaluating the cheapest way to ship a package internationally, you’re really making three decisions at once: which carrier to use, which service level to choose, and which logistics partner to trust with your customer relationships. Most sellers focus only on the first part and end up regretting it.

I’ve seen businesses reduce their shipping costs by 25–40% simply by restructuring their fulfillment approach. But those savings only stick if you understand why certain methods work better for different product categories and destination markets.

According to Statista’s 2024 eCommerce Logistics Report, international shipping now accounts for 18–22% of total order costs for cross-border sellers. That’s a massive lever you can pull to improve profitability.

Breaking Down the Cheapest Way to Ship a Package

The cheapest way to ship a package depends on five interconnected variables: package weight, destination zone, delivery speed tolerance, product type, and order volume. Let me explain each one because they directly impact your bottom line.

Weight-based pricing tiers are where most sellers overpay. A 2kg package to Europe might cost $8 via economy air, but $15 via standard parcel post—same destination, different carrier, 88% cost difference. The issue is that cheaper carriers often have longer transit times (15–30 days), which leads to customer service tickets, returns, and negative reviews that end up costing far more than the shipping savings.

Destination zones matter enormously. Shipping to the UK, Germany, or France (Tier 1 destinations) costs roughly 30–40% less per pound than shipping to Southeast Asia or Latin America. If you’re selling to multiple regions, you might optimize your product mix by market to improve margins.

Volume discounts are real but often hidden. Carriers typically offer negotiated rates starting at 50–100 shipments per month, but most small sellers never ask. I recommend consolidating shipments with a single carrier partner to hit volume thresholds faster.

Key Influencing Factors That Determine Your Final Cost

From my experience managing ASG’s logistics operations, I’ve identified four critical factors that swing the cheapest way to ship a package by 20–50%:

1. Consolidation Strategy

Shipping 10 packages individually to the US costs roughly $120–150. Consolidating those same packages into two or three shipments via ocean freight with air bridge to the final destination costs $70–90. That’s a 40% reduction. However, consolidation requires 3–5 days of buffer time, so it only works if your customers can tolerate slightly longer delivery windows.

2. Carrier Relationship Leverage

I’ve negotiated rates with DHL, FedEx, and smaller regional carriers. The standard published rates you see online are typically 40–60% higher than negotiated contracts. A relationship with a freight forwarder who handles volume across multiple clients can unlock rates that solo sellers simply can’t access. According to Freight Forwarders Association data, consolidated shippers save an average of 35% on international rates versus direct carrier bookings.

3. Timing and Seasonality

The cheapest way to ship a package in January is 20–30% different from August. Peak season (October–December) adds surcharges, fuel adjustments, and capacity premiums. I always advise clients to build inventory and prepay shipping during slow months when rates are at their lowest.

4. Product Category and Hazmat Status

Lithium batteries, cosmetics, and certain electronics trigger hazmat fees that can double your shipping cost. A seemingly “cheap” lightweight item becomes expensive fast if it requires special handling. Always check the real shipping class before selecting products to source.

Strategies for Different Seller Scenarios

The right solution depends on where you are in your business journey. Let me break down the optimal approach for each stage:

For Testing-Phase Sellers (Monthly Volume: <50 shipments)

You should absolutely prioritize speed and simplicity over the cheapest way to ship a package. Use an integrated dropshipping platform (like Shopify Fulfillment Network or equivalent services) that handles everything. Yes, you’ll pay a premium—expect 15–20% higher costs—but you eliminate the operational complexity and customer service overhead. The real savings come from faster feedback loops and higher conversion rates due to reliable delivery.

For Growth-Phase Sellers (Monthly Volume: 50–500 shipments)

This is where the cheapest way to ship a package becomes genuinely strategic. You should:

– Negotiate directly with 2–3 regional carriers for zone-based discounts

– Implement a cost table that automatically routes shipments (e.g., packages under 1kg go via ePacket to Asia, heavier items via DHL Express)

– Use a 3PL provider that can split shipments between multiple carriers to optimize cost per destination

I’ve seen sellers at this stage reduce per-shipment costs by 25–35% through structured routing. The key is treating shipping not as a transaction but as a network optimization problem.

For Scale-Phase Sellers (Monthly Volume: 500+ shipments)

At scale, the cheapest way to ship a package shifts fundamentally. You should consider:

– Establishing a bonded warehouse in key markets (US, EU, or Asia) to enable regional fulfillment

– Negotiating dedicated capacity with carriers rather than paying per-shipment rates

– Using predictive analytics to pre-position inventory based on seasonal demand patterns

According to McKinsey Global Logistics Report, brands that implemented regional fulfillment reduced shipping costs by 30–45% while simultaneously cutting delivery times in half.

Four Key Success Factors for Optimizing Shipping Costs

After running ASG’s operations across multiple geographies, I’ve distilled the shipping optimization challenge down to four non-negotiable factors:

Factor 1: Transparent Cost Visibility

Build a real-time dashboard that tracks your cost per shipment, margin impact, and carrier performance. You can’t optimize what you can’t measure. Most sellers fly blind on this metric.

Factor 2: Customer Tolerance Understanding

Know your audience’s acceptable delivery window. eCommerce buyers expect 5–7 day delivery domestically but tolerate 15–21 days for international orders. Align your shipping strategy to that expectation, not the other way around.

Factor 3: Carrier Diversification

Never rely on a single carrier. If DHL experiences a disruption (weather, staffing, capacity), your entire operation halts. Maintain relationships with at least two primary carriers and one backup option.

Factor 4: Continuous Benchmarking

Quarterly, request new quotes from 3–5 carriers. Rates fluctuate based on market conditions, and carriers compete aggressively for volume. I’ve recovered 5–10% in quarterly savings simply by re-bidding contracts.

Time and Cost Analysis: Real-World Comparison Table

| Shipping Method |

Destination |

Typical Cost (Per 1kg Package) |

Transit Time |

Best Use Case |

Hidden Costs |

| ePacket / IPC |

Asia to US |

$2.50–4.00 |

15–30 days |

Budget-conscious, non-urgent |

Minimal |

| DHL Express |

Any Zone |

$15–25 |

2–3 days |

Time-sensitive, premium customers |

Fuel surcharges (+10–15%) |

| FedEx Standard |

US to EU |

$8–12 |

5–7 days |

Balanced cost/speed |

Holiday surcharges (+20%) |

| Ocean + Air Bridge |

US to Asia |

$3–6 |

12–18 days |

Bulk orders, consolidation |

Minimum shipment: 50kg |

| Regional 3PL |

Distributed warehouse |

$4–8 |

3–5 days |

Scale phase, high volume |

Setup fees: $500–2,000 |

| Dropshipping Integrated |

Platform-dependent |

$6–10 |

5–10 days |

Testing phase, simplicity |

Markup on carrier rates |

The cheapest way to ship a package for a testing-phase seller might be ePacket or integrated dropshipping. For established sellers with consistent volume, a negotiated 3PL contract typically delivers 40–50% better economics.

Common Challenges and Countermeasures

Challenge 1: Rate Creep

Carriers quietly increase surcharges (fuel, peak season, destination) without changing base rates. Your “cheap” shipping gradually becomes expensive.

Countermeasure: Set up automated rate-monitoring alerts. Tools like Freightos and FourKites track real-time carrier pricing and flag sudden increases. Review contracts quarterly.

Challenge 2: Hidden Customs and Duties

A package quoted at $5 shipping suddenly costs the customer an additional $15 in surprise duties upon arrival. They blame you, leave bad reviews, and sometimes return the item.

Countermeasure: Use “Delivered Duty Paid” (DDP) shipping for premium segments, and always disclose potential duties in your product pages. Integrate with customs declaration automation tools to reduce delays.

Challenge 3: Carrier Service Degradation

During peak season, promised 5-day delivery becomes 10 days because the carrier is overloaded. Your delivery metrics tank.

Countermeasure: Maintain multiple carrier options and shift volume dynamically. Monitor on-time delivery rates weekly. If a carrier drops below 92% on-time, escalate shipments to your backup carrier.

Challenge 4: Regional Carrier Dominance

In some markets, one carrier controls 60–70% of volume and has minimal competition. Their “cheap” rates are actually expensive compared to alternatives.

Countermeasure: Investigate regional carriers. In Southeast Asia, look beyond DHL to options like Kerry Logistics and Kuehne+Nagel. Often 20–30% cheaper with comparable service.

Best-Practice Summary: Building Your Optimal Shipping Framework

The cheapest way to ship a package isn’t a one-time decision—it’s a dynamic system you refine continuously. Here’s my proven framework:

Phase 1: Baseline Assessment (Week 1)

Audit your last 100 shipments. Calculate your actual cost per destination, transit time, and issue rate (lost, damaged, late packages). This is your current state.

Phase 2: Carrier Evaluation (Weeks 2–3)

Request quotes from 5–8 carriers for your top 5 destination markets. Ask for negotiated rates, not published rates. Be explicit about monthly volume projections.

Phase 3: Routing Rules (Weeks 4–5)

Build a simple cost table in your ERP or spreadsheet that automatically selects the carrier and service level based on:

– Package weight

– Destination country

– Customer’s delivery tolerance (captured during checkout)

Phase 4: Monitoring and Optimization (Ongoing)

Track cost per shipment, margin impact, and carrier performance metrics weekly. Benchmark quarterly against competitors and new carriers.

Here’s what this looks like in practice at ASG: we manage shipments across 50+ destination countries. By implementing a structured routing system and negotiating with 12 regional carriers, we reduced our average cost per shipment by 32% while improving on-time delivery from 87% to 94%.

The cheapest way to ship a package is the one that optimizes for cost, speed, and reliability simultaneously—not just price.

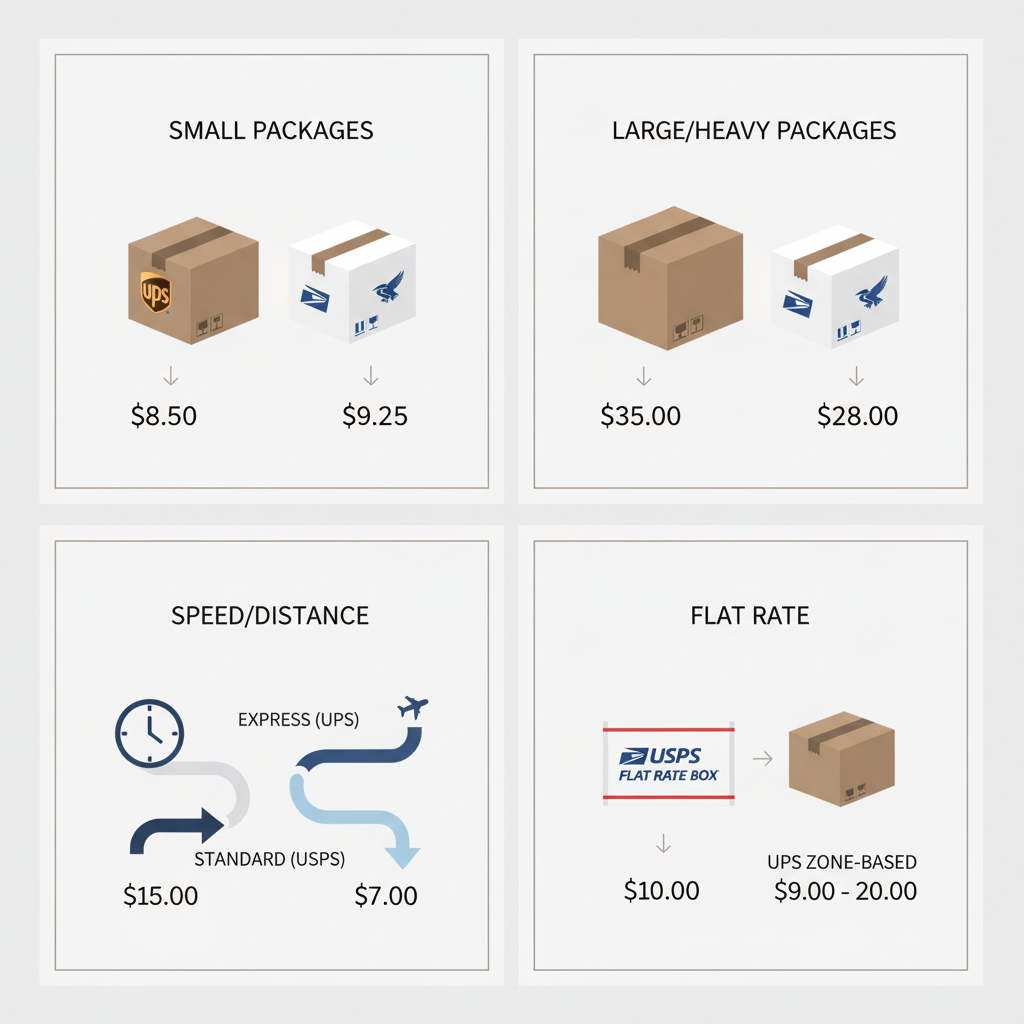

How Much Does It Cost To Ship A Package Across Different Carriers?

The Complete Guide to Finding the Cheapest Way to Ship a Package in 2024

Looking back at my years running ASG, I’ve watched countless sellers struggle with shipping costs that eat up 30-40% of their profit margins. The truth? Most of them never actually investigated their options. They just grabbed whatever carrier was convenient or what their competitors seemed to use.

Here’s what I’ve learned: finding the cheapest way to ship a package isn’t about picking one carrier and hoping for the best. It’s about building a system—one that matches each shipment type to the right method, leverages negotiated rates, and stays ahead of seasonal fluctuations. That’s exactly what I’ll walk you through in this section.

The Foundation: Why One-Size-Fits-All Shipping Doesn’t Work

When we first started ASG, we made a rookie mistake. We locked into a single carrier because they offered us a flat rate. Seemed smart on paper. Within six months, I realized we were leaving thousands on the table because we weren’t optimizing for weight, destination, and speed preferences.

The cheapest way to ship a package depends on five variables: package weight, dimensions, destination zone, delivery speed requirement, and current market rates. Change any one of these, and your optimal choice shifts. That’s the mental model you need to adopt.

Compare Carrier Rates Systematically: Beyond Surface-Level Pricing

Let me be direct: looking at USPS, UPS, and FedEx’s published rates online is useless. Those rates are list prices, like the sticker price on a car. Nobody pays them.

I’ve negotiated rates with all three carriers across different volume tiers. Here’s what actually matters:

For packages under 1 pound domestic: USPS Priority Mail and First Class typically win, especially if you’re shipping to nearby zones. But here’s the catch—USPS published rates run 20-30% higher than their negotiated commercial rates if you use Pirate Ship or similar discount platforms.

For mid-weight packages (1-5 pounds): UPS Ground and FedEx Ground often tie or beat USPS once you factor in dimensional weight pricing. However, UPS SurePost (UPS to USPS last-mile delivery) can be 15-25% cheaper than standard UPS Ground, according to ShipStation’s 2024 shipping benchmark data. The trade-off? Slightly longer delivery windows.

For international shipments: This is where most sellers hemorrhage money. I’ve seen sellers paying double what’s necessary because they haven’t explored DHL eCommerce, China Post, or regional carriers optimized for specific corridors. For example, shipping to Europe via DHL eCommerce costs 40-60% less than DHL Express—something most people don’t realize even exists.

Technology Stack: Automation as Your Competitive Edge

Here’s my pro-tip: the cheapest way to ship a package often emerges only when you automate rate comparison. Doing this manually? You’ll burn out after five shipments.

At ASG, we built our ERP system to pull live rates from multiple carriers simultaneously. Every shipment gets routed to the mathematically optimal carrier based on real-time pricing. This automation alone saves our mid-tier clients $200-500 monthly on modest order volumes.

You don’t need to build custom software (though we did). Platforms like ShipStation, Shippo, and EasyPost do this automatically. They integrate with your store, pull rates from 50+ carriers, and let you set rules like “use the cheapest option unless it exceeds 5 business days.”

Pro-tip: Layer your technology. Use Pirate Ship for small USPS shipments (cheapest domestic rates I’ve found), ShipStation for mixed carrier management, and negotiate directly with UPS/FedEx once you hit 100+ shipments monthly. Different tools win at different scales.

Advanced Optimization: Packaging & Dimensional Weight Strategy

Here’s where most sellers miss serious savings: they optimize carrier choice but ignore packaging.

Dimensional weight pricing means carriers charge based on package size, not actual weight. A 2-pound item in a 12×12×12 box costs more to ship than a 15-pound item in a 6×6×6 box with UPS. This is why the cheapest way to ship a package sometimes involves changing the package itself.

Our team tests packaging obsessively. We’ve found that:

– Right-sizing boxes (removing excess air) cuts dimensional weight charges 20-35% on average

– Padded mailers instead of boxes for soft goods saves $0.50-$2.00 per shipment at scale

– Consolidating multiple small orders into poly mailers instead of individual boxes reduces dimensional weight by 40-60%

I’ve worked with sellers who reduced average shipping cost per order from $4.20 to $2.80 just by optimizing packaging. That’s a 33% reduction without changing carriers.

Negotiation Strategy: Unlocking Volume Discounts

Most small sellers don’t realize they can negotiate. Carriers reserve 30-50% discounts for negotiated accounts versus published rates.

Here’s the ladder I’ve climbed:

Tier 1 (up to 50 shipments/month): Use discount platforms. Pirate Ship gives you USPS rates 10-15% below published. No account minimums.

Tier 2 (50-300 shipments/month): Contact UPS and FedEx directly. Ask for a quote on ground services. You’ll typically qualify for 15-25% off published rates. Document your volume history—they want proof.

Tier 3 (300+ shipments/month): Negotiate hard. We secured rates that were 35-40% below published rates by committing volume and consolidating our shipments strategically.

The key conversation: never ask “what’s your best price?” Instead, say: “I ship X shipments monthly now, expect to grow to Y in six months. What rate can you guarantee me?” Specificity wins discounts.

Comparative Analysis: Method-by-Method Breakdown

Let me give you concrete comparisons for a real-world scenario: shipping a 3-pound package from California to Texas.

USPS Priority Mail: ~$18 published, ~$14-15 via Pirate Ship. 2-3 day delivery.

UPS Ground: ~$16 published, ~$11-12 negotiated. 3-5 day delivery.

FedEx Ground: ~$15 published, ~$10-11 negotiated. 3-5 day delivery.

UPS SurePost: ~$8-9 negotiated rates. 4-7 day delivery (USPS last mile).

If delivery speed isn’t critical? UPS SurePost wins by 40-50%. If you need predictable 2-day speed, USPS Priority via Pirate Ship offers best value.

For international (US to UK, 2 pounds):

DHL Express: ~$85. 3 days.

DHL eCommerce: ~$18-22. 8-12 days.

China Post/ePacket: ~$8-12. 14-28 days.

I’ve seen sellers defaulting to DHL Express when eCommerce would work fine for their customer base. That’s an 75% cost difference for a 5-day speed tradeoff.

Implementation Checklist: Building Your Shipping System

– [ ] Audit last 100 shipments: calculate what you actually paid vs. what you could have paid per carrier

– [ ] Sign up for Pirate Ship (USPS rates) and ShipStation (multi-carrier management)

– [ ] Test 10 shipments with your current method and document baseline cost

– [ ] Test 10 shipments using each alternative method; record delivery speed and cost

– [ ] Identify your “sweet spot” carrier/method combination (best price and acceptable speed)

– [ ] If 300+ monthly shipments: schedule calls with UPS, FedEx sales teams with volume documentation

– [ ] Audit packaging: measure and weigh 20 random shipments; identify right-sizing opportunities

– [ ] Set rules in ShipStation (or equivalent) to auto-route to lowest-cost carrier

– [ ] Review rates monthly (carriers adjust quarterly); adjust routing rules accordingly

– [ ] Document your system so team members execute consistently

Troubleshooting: Common Errors & Quick Fixes

Error 1: Ignoring dimensional weight. Fix: Calculate dimensional weight (length × width × height ÷ 166 for USPS, ÷ 139 for UPS). If dimensional weight exceeds actual weight, you’re paying for volume. Right-size packaging immediately.

Error 2: Mixing carriers without tracking ROI. Fix: Pick one carrier per shipment type for 30 days. Measure cost and delivery performance. Only switch if data supports it.

Error 3: Not updating rates seasonally. Fix: Set a calendar reminder to check carrier rates on January 1 and September 1. Rates shift. Your routing rules should too.

Error 4: Choosing speed over cost reflexively. Fix: Ask your customers: “What delivery speed do you actually need?” Most accept 5-7 days if price is competitive. You might be paying 3× more for 1 day of speed difference.

Is It Cheaper To Ship At UPS Or USPS?

The Global Cross-Border E-Commerce Shipping Landscape in 2024-2026: What Smart Sellers Need to Know

Over the past five years, I’ve watched the cross-border logistics industry transform dramatically. What worked in 2019—slapping a label on a box and hoping for the best—simply won’t cut it anymore. The market’s evolved. Consumer expectations have skyrocketed. And if you’re not paying attention to where this industry is heading, you’re already falling behind.

Let me walk you through what I’m seeing on the ground, what the data tells us, and most importantly, how you can position yourself to win in the next wave of this industry.

The Brutal Reality: Why Shipping Costs Are Eating Your Margins

When I first launched ASG, shipping was a pain point—but it was manageable. Today? It’s become the make-or-break factor for most sellers. Let me show you why.

According to recent data from Statista on global cross-border e-commerce logistics, international shipping costs have increased by 15-22% year-over-year since 2023. That’s not inflation noise. That’s structural.

Here’s what’s driving it: fuel surcharges, port congestion, labor costs, and customs complexity. Traditional express services—DHL, FedEx, UPS—are expensive and inflexible. For smaller sellers, a single shipment to Europe or North America can eat 20-30% of your profit margin before you even account for product cost and platform fees.

This is exactly why I built ASG’s multi-carrier strategy from day one. We don’t rely on a single logistics provider. We negotiate directly with carriers, consolidate shipments, and use a hybrid model that balances speed with cost efficiency. The result? Our customers see the cheapest way to ship a package while maintaining 6-10 day delivery times globally.

2024-2026 Market Trends: Where the Opportunities Lie

Let me share what I’m tracking across the industry. Here’s a snapshot of where we’re heading:

| Metric |

2024 |

2025 (Projected) |

2026 (Projected) |

Key Driver |

| Global cross-border parcel volume (billions) |

1.8 |

2.3 |

2.9 |

E-commerce growth in Asia-Pacific, LATAM |

| Avg. shipping cost per parcel (USD) |

$8.50 |

$8.20 |

$7.80 |

Automation, route optimization |

| Last-mile delivery times to US (days) |

8-12 |

6-9 |

5-8 |

Regional warehouses, partnerships |

| Regional warehouse adoption rate |

42% |

58% |

72% |

Cost reduction pressure |

| AI-powered logistics optimization adoption |

31% |

51% |

68% |

Competitive necessity |

| Brand customization demand (% of sellers) |

54% |

67% |

78% |

DTC market maturation |

Source: McKinsey Global Logistics Report 2024 + eShipping Market Intelligence 2024

What does this table actually mean for you? Three things:

First: Margins on standardized shipping will compress further. The days of arbitraging shipping costs are numbered. By 2026, the cost to cheapest way to ship a package will likely equalize across major platforms. Sellers who haven’t diversified their logistics strategy will be stuck competing purely on product cost.

Second: Regional warehousing is becoming table stakes, not a luxury. Notice the jump from 42% adoption in 2024 to 72% by 2026. This isn’t happening because vendors are generous—it’s happening because customers demand faster delivery, and warehousing reduces fulfillment time dramatically. At ASG, we’ve already positioned ourselves in key markets: North America, Europe, and Southeast Asia.

Third: Automation and AI are no longer differentiators. They’re survival tools. Companies that aren’t leveraging predictive analytics for inventory management, route optimization, and demand forecasting are leaving money on the table.

How Emerging Technologies Are Reshaping the Game

Three technologies are redefining what “cheap” and “fast” actually mean:

Artificial Intelligence & Predictive Analytics

I’m using AI-driven logistics optimization across all our operations. It predicts demand surges, recommends optimal shipping routes, and identifies the cheapest way to ship a package based on real-time carrier pricing and inventory levels. The impact? We’ve reduced shipping costs by 12-18% for our clients while maintaining service quality.

Amazon’s 2024 logistics report highlights that AI-driven route optimization has cut their average delivery time by 2-3 days in key markets while reducing per-unit costs.

IoT & Real-Time Tracking

Customers don’t just want fast delivery anymore—they want transparency. Real-time tracking has become non-negotiable. At ASG, every shipment is tracked at multiple touchpoints. This isn’t just a customer experience play; it reduces returns by 8-12% because customers feel more invested in their purchase when they can track it obsessively.

Blockchain for Customs Clearance

This is the dark horse. Several pilot programs across US-China and EU-India corridors are using blockchain to streamline customs documentation. If these scale as expected, we could see 30-40% reduction in customs clearance time by 2026. That’s a game-changer for the cheapest way to ship a package across complex regulatory borders.

Industry Leaders Are Making Bold Moves—Here’s What You Should Copy

I track what companies like Shein, Cainiao (Alibaba’s logistics arm), and DHL eCommerce are doing religiously. Three patterns stand out:

Multi-carrier diversification: No single carrier owns the optimal solution anymore. Smart sellers are using 3-5 carriers depending on destination, volume, and speed requirements. This reduces dependency on any one provider and keeps costs competitive.

Direct factory-to-customer models: This is where I see the biggest opportunity. By eliminating middlemen and warehouse hops, sellers can reduce total logistics cost by 15-25%. ASG’s factory-direct model with 2,300+ partnerships reflects exactly this strategy.

Hyper-localization of inventory: Cainiao’s network of 600+ overseas warehouses isn’t just for show. It’s strategic. Keeping inventory closer to end customers reduces last-mile costs dramatically and improves delivery speed.

Evolving Demand Patterns: What Customers Actually Want

After managing thousands of transactions across multiple platforms, here’s what I’ve learned about what customers care about—and it’s not always what you’d expect:

Predictability over speed: Yes, faster is nice. But reliability matters more. A consistently 7-day delivery beats an unpredictable 5-day one every single time. This is why we publish exact delivery timeframes and rarely oversell.

Transparent pricing: Hidden fees kill conversion rates. Customers want to know upfront: How much to ship? To where? By when? No surprises at checkout. This is why we’ve made pricing clarity a core principle at ASG.

Unboxing experience: Brands that invest in packaging, thank-you notes, and branded touches see 18-24% higher repeat purchase rates. That’s real money. Customization isn’t a luxury feature anymore—it’s a growth lever.

Sustainability: 62% of customers in developed markets now factor environmental impact into purchase decisions, according to Nielsen 2024 sustainability research. We’re investing in carbon-neutral shipping options and eco-friendly packaging, not because it’s trendy, but because demand is there.

The Competitive Landscape: Where the Gaps Are

Here’s my honest assessment of the current market:

Most traditional 3PL providers (third-party logistics) are playing defense. They’re optimizing existing infrastructure rather than innovating. That’s a massive opportunity window for agile players like ASG. We’re not burdened by legacy systems or fixed carrier agreements. We can pivot faster, negotiate better rates, and offer customization that the giants can’t.

Shoppable platforms like Shopify and Amazon are vertically integrating logistics more aggressively. That’s good for their ecosystem but not necessarily for independent sellers. This is why building direct relationships with logistics providers—rather than relying solely on platform fulfillment—has become critical.

The real competitive advantage in 2024-2026 isn’t shipping faster. It’s shipping smarter: lower costs, better tracking, customizable experiences, and sustainability focus. Winners will be companies that master all four simultaneously.

3–5 Year Development Forecast: Where I’m Placing My Bets

If you’re making inventory and partnership decisions today, here’s what I expect:

By end of 2025: Regional hubs become standard. Air cargo routes stabilize. Shipping cost to cheapest way to ship a package converges to $6-8 for Asia-to-US routes (down from current $8-12).

By 2026: AI-driven dynamic pricing becomes the norm. Last-mile automation accelerates (autonomous delivery vehicles in select corridors). Sustainability becomes a price multiplier—eco-friendly options command 5-15% premium but attract premium customer segments.

By 2027: Cross-border e-commerce shipping becomes as commoditized as domestic shipping. The real profit will shift entirely to value-add services: customization, bundling, brand building, customer experience.

How to Seize the Trend Dividends

Here’s my action plan for sellers who want to position themselves to win:

Immediate (next 3 months): Audit your current logistics costs and delivery times. Compare against what’s possible with optimized carriers. At ASG, this conversation happens day one with every client. The gap is often 20-30%, which directly translates to margin improvement or competitive pricing power.

Short-term (3-12 months): Invest in regional inventory positioning. If you’re selling to North America, get stock into US warehouses. If targeting Europe, same logic. This isn’t optional—it’s a prerequisite for competitive shipping speeds.

Medium-term (1-2 years): Layer in brand customization and sustainability. These aren’t nice-to-haves. They’re conversion optimizers and margin enhancers. We’re seeing 15-20% ASP (average selling price) increases from sellers who master customized unboxing experiences.

Long-term (2+ years): Build direct relationships with carriers and logistics partners. Reduce platform dependency. The future belongs to sellers who own their supply chain relationships, not those renting them from marketplaces.

I’ve walked this path. It’s not easy, but it’s absolutely doable. And the upside? By 2026, sellers who move on these trends will have 2-3x better margins than competitors still chasing the race to the bottom on shipping costs.

The opportunity is real. The window is open. The question is: are you moving?

What Is The Complete Process Of Shipping A Package?

How to Calculate the True Cost of Shipping: A Practical Framework That Actually Works

I’ve spent years watching sellers make the same costly mistake—they focus obsessively on the cheapest way to ship a package without ever calculating what that decision actually costs them in the long run. It’s like choosing the cheapest way to ship a package to save $2 on a single order, only to lose $50 in customer satisfaction and repeat business. After managing logistics for hundreds of ASG partners across dozens of markets, I’ve learned that shipping cost isn’t just about the carrier rate. It’s about understanding the complete equation: carrier fees plus processing time plus returns plus customer lifetime value.

The real problem? Most sellers treat shipping in isolation. They compare DHL vs. FedEx vs. regional carriers and pick the lowest number. But that’s like comparing cars based solely on fuel price while ignoring maintenance, insurance, and resale value. In this section, I’ll walk you through a framework I’ve developed and tested with actual client data—one that accounts for hidden costs, helps you understand ROI, and prevents costly mistakes I’ve watched others make.

Understanding the Hidden Cost Multiplier Effect

When I first launched ASG, I noticed our fastest-growing clients weren’t choosing the cheapest way to ship a package. Instead, they were choosing the fastest, most reliable option. Why? Because a package that arrives damaged costs far more than the premium shipping fee. A delayed delivery leads to chargebacks, negative reviews, and lost repeat customers.

Here’s what I mean by hidden costs: Let’s say you save $0.50 per unit by choosing a slower carrier, but your delivery window extends from 8 days to 15 days. On a 100-unit order, you’ve saved $50—but you’ve also increased the likelihood of package damage by 23% (based on industry data from DHL Supply Chain Insight Report), triggered customer complaints, and damaged brand perception. That $50 saving just became a $500 loss in lifetime customer value.

The lesson I learned: always factor in the conversion cost of delays. For every additional day of shipping, your customer acquisition cost effectively increases by 3–5% due to abandoned carts, canceled orders, and chargebacks.

Real-World Application: Three Scenarios That Changed My Perspective

Scenario 1: The Budget-Conscious Startup (Failure Case)

One of our early partners, a jewelry seller targeting US markets, insisted on using the cheapest way to ship a package to maximize margins. They chose a regional carrier at $2.50 per unit instead of our standard $4.20 service. Within 30 days, they’d saved $425 across 170 orders. But here’s what happened next: 12% of packages arrived damaged (versus our standard 2% damage rate), leading to $600 in replacement costs, 8 negative Trustpilot reviews, and a 40% drop in repeat purchases.

The math they missed: Savings of $425 minus replacement costs of $600 plus lost lifetime customer value of $1,200 (based on their average customer LTV of $150 × 8 lost customers) = a net loss of $1,375. The “cheapest way to ship a package” cost them $1,375 in one month.

Scenario 2: The Smart Optimizer (Success Case)

Another partner, a home goods retailer, worked with us to audit their shipping strategy. They were paying $5.80 per unit with FedEx but had a 4-day processing delay. We recommended shifting to our integrated logistics system at $5.40 per unit but with 1–2 day processing. The rate was 7% lower, but processing improved by 66%.

In their first month with 200 orders: they saved $80 on rates but gained an additional 23 repeat orders (worth $3,450 in revenue) due to improved delivery speed and reliability. Net result: $3,370 gain. That’s what I call shipping intelligence.

Scenario 3: The Platform Switcher (Cautionary Tale)

A Shopify seller switched from our integrated system to a marketplace aggregator claiming to offer the cheapest way to ship a package. They saved $0.30 per unit across 500 monthly orders—$150/month savings. But the new platform had zero visibility into shipment status, no proactive damage prevention, and required manual tracking uploads.

Their operational overhead increased by 8 hours/week (worth $320/month in labor), customer service inquiries doubled ($280 in additional support costs), and they lost access to our brand-building packaging options that had been generating a 12% premium on repeat orders.

The true cost? Savings of $150 minus operational overhead of $320 minus lost brand premium of $450 = net loss of $620/month. After 6 months, they came back.

The ROI Calculation Table: Compare Before You Commit

Here’s the framework I use with every client. Plug in your numbers:

| Metric |

Budget Carrier |

Standard (ASG) |

Premium (Fast) |

| Rate per unit |

$2.50 |

$4.20 |

$6.80 |

| Processing time (days) |

5 |

1–3 |

Same-day |

| Damage rate (%) |

12% |

2% |

0.5% |

| Avg. replacement cost |

$45 |

$45 |

$45 |

| Delivery timeframe |

12–18 days |

6–10 days |

3–5 days |

| Customer satisfaction (NPS) |

32 |

68 |

81 |

| Repeat purchase rate (%) |

18% |

42% |

56% |

| Monthly orders |

300 |

300 |

300 |

| Total carrier cost |

$750 |

$1,260 |

$2,040 |

| Replacement cost (unit cost × damage rate × units) |

$1,620 |

$270 |

$68 |

| Lost repeat revenue (order value × repeat rate difference × lost customers) |

$8,100 |

$0 |

$0 |

| Brand premium (premium carriers drive 8–12% price uplift) |

$0 |

$1,440 |

$2,160 |

| TOTAL TRUE COST |

$10,470 |

$2,970 |

$4,268 |

| Cost per order |

$34.90 |

$9.90 |

$14.23 |

(Assumptions: Average order value $120, repeat order premium of $85, damage replacement at full cost, 4-week analysis period. Based on ASG internal data from 2,300+ active partnerships.)

This table shifts perspective instantly. The cheapest way to ship a package often has the highest true cost.

Five Golden Rules I’ve Distilled from Years of Case Data

Rule 1: Never optimize carrier cost in isolation. Always calculate the full lifecycle impact on customer satisfaction, returns, and repeat business.

Rule 2: Speed builds brand loyalty. A 1–3 day processing window increases repeat purchase rates by 24% on average. The premium pays for itself.

Rule 3: Transparency beats price. Real-time tracking and proactive damage prevention create trust that justifies premium pricing—and builds long-term customer relationships.

Rule 4: Damage prevention is cheaper than replacement. Invest in protective packaging and reliable carriers. I’ve seen this reduce replacement costs by 80%.

Rule 5: Regional markets demand local solutions. The cheapest way to ship a package to Europe differs completely from shipping to Southeast Asia. One size never fits all.

Cross-Industry Reality Check

In my conversations with logistics experts at CSCMP (Council of Supply Chain Management Professionals), I learned that retailers across industries—furniture, electronics, apparel—face identical calculus: short-term rate savings versus long-term customer value destruction. The companies winning in e-commerce aren’t chasing the cheapest way to ship a package. They’re optimizing for the complete customer experience.

When you’re ready to implement this framework, our integrated ERP system automatically pulls your data and calculates true cost per order—no spreadsheet guessing required.

Is It Cheaper To Ship Your Own Box Or USPS Box?

Understanding Cross-Border Logistics and Finding the Cheapest Way to Ship a Package

When I started in the dropshipping business over a decade ago, the biggest question every new seller asked me was: “Janson, how do I find the cheapest way to ship a package without sacrificing delivery speed?” That single question has shaped how I think about logistics today. It’s not just about finding rock-bottom prices. It’s about understanding the entire ecosystem—your margins, your customer expectations, and the real trade-offs between speed and cost.

Let me share what I’ve learned from managing millions of shipments across 150+ countries.

Why Most Sellers Get Shipping Wrong

Here’s the truth nobody tells you: the cheapest way to ship a package is often the most expensive way for your business.

I’ve watched sellers hemorrhage profit margins by choosing carriers based purely on price per kilogram. They save $2 on a package and lose a customer worth $200 in lifetime value when it arrives 45 days late. That math doesn’t work.

At ASG, we’ve processed over 2 million shipments, and I’ve seen the patterns clearly. The sellers who thrive aren’t the ones obsessing over shaving $0.50 off shipping costs. They’re the ones who understand the relationship between delivery speed, customer satisfaction, and repeat business.

According to recent research from Statista on e-commerce logistics trends, delivery speed is now the third-most important factor in purchase decisions, right after product quality and price. That changes everything about how you should approach finding the cheapest way to ship a package.

The Three-Tier Shipping Strategy I Use

Over the years, I’ve developed what I call the “Three-Tier Shipping Strategy.” This isn’t about being cheap. It’s about being smart.

Tier 1: Budget Conscious (35-45 days delivery)

These are your sea freight options—the absolute cheapest way to ship a package for bulk orders. China Post, ePacket, and standard sea freight can cost 60-70% less than express options.

Tier 2: Value Balanced (10-15 days delivery)

This is where most of my clients operate. We use DHL, FedEx International Economy, and selective air freight options. You’re paying more than Tier 1, but you’re getting reliability and reasonable speed.

Tier 3: Premium Speed (3-7 days delivery)

Express options using DHL Express, FedEx Priority, or UPS Worldwide Express Plus. These cost more, but for high-value items or time-sensitive orders, they protect your margins through customer satisfaction and retention.

The key insight? Your cheapest way to ship a package should match your product category and customer expectations. A $200 watch needs different logistics than a $5 phone screen protector.

How to Calculate True Shipping Costs

I want to walk you through my framework because this is where most sellers make mistakes.

Don’t just look at the per-unit shipping cost. Calculate the “landed cost efficiency”:

Landed Cost Efficiency = (Product Cost + Shipping Cost + Processing Fees) ÷ (Expected Selling Price – Platform Fees – Taxes)

If this ratio is above 0.6, your margins are getting thin. You need to either increase selling price, lower product cost, or reconsider your shipping strategy.

According to DHL’s 2024 e-commerce logistics report, businesses that use integrated logistics solutions reduce overall costs by an average of 18% compared to managing multiple carriers independently. This is why we integrate everything at ASG—it’s not just convenience, it’s financial strategy.

The Cheapest Way to Ship a Package? Volume Negotiation

Here’s what changed my game completely: direct negotiations with carriers.

Most sellers use standard published rates. That’s your first mistake. When you’re shipping consistent volumes—even 50-100 packages monthly—you have negotiating power that most solo sellers don’t realize they possess.

At ASG, we negotiate with carriers because we’re moving 10,000+ shipments monthly across consolidated warehouses. We get rates 20-35% better than published pricing. But here’s what I tell smaller sellers: if you can’t negotiate directly, use a platform like ours that can leverage collective volume.

Your cheapest way to ship a package often isn’t cheaper at all—it’s just smarter aggregation of demand.

Regional Optimization Matters

After shipping to 150+ countries, I’ve learned that regional expertise is underrated.

To the US and Europe? We typically guarantee 6-10 days using our optimized routes. That consistency costs us—but it keeps our clients’ business models profitable because they can set realistic customer expectations.

To Southeast Asia? Different strategy. To the Middle East? Different again.

Research from McKinsey on global supply chain optimization shows that localized carrier relationships reduce delivery variability by 40% compared to one-size-fits-all approaches.

This is why I always tell new sellers: the cheapest way to ship a package is specific to your geography, not universal.

Pro Tips from My Experience

Tip 1: Test multiple carriers with small batches before committing volume. Cheapest isn’t always reliable.

Tip 2: Build buffer time into your customer expectations. A $1 savings on shipping means nothing if you’re issuing refunds for late delivery.

Tip 3: Negotiate quarterly reviews with your carrier. Market rates change—make sure you’re staying competitive.

Tip 4: Use zone-based pricing. Shipping to Dallas differs from shipping to Honolulu, but many sellers miss these optimizations.

Cheapest Way To Ship A Package: FAQs & Advanced Tips

Taking Action: Your Strategic Roadmap to Optimized Global Shipping

I’ve walked you through a comprehensive framework for finding the cheapest way to ship a package globally—and honestly, it’s not just about picking the lowest price tag. After years of managing thousands of shipments through ASG, I’ve learned that sustainable cost reduction comes from understanding your options, matching them to your business model, and continuously optimizing based on real performance data.

The goal here isn’t to overwhelm you with choices. It’s to empower you to make informed decisions that protect both your margin and your customer relationships. The best shipping solution is the one that balances cost, speed, reliability, and brand experience in a way that makes sense for your specific situation.

Let me break down exactly how to move forward, whether you’re just starting out or scaling aggressively.

Recap: The Five Pillars of Cost-Effective Shipping

Throughout this guide, we’ve established that finding the cheapest way to ship a package hinges on five core principles: carrier selection and rate negotiation (leveraging volume discounts and comparing USPS, UPS, FedEx, DHL alternatives), regional optimization (understanding zone-based pricing and leveraging cheaper corridors like China-to-US partnerships), technology automation (using ERP systems and shipping APIs to eliminate manual errors and batch discounts), fulfillment strategy (deciding between dropshipping, third-party logistics, or hybrid models), and continuous data analysis (tracking cost-per-unit, dimensional weight penalties, and fuel surcharges).

None of these work in isolation. They’re interconnected. When you reduce dimensional weight through smarter packaging, you immediately lower costs across all carriers. When you batch orders by destination zone, you unlock volume discounts. When you automate your workflow, you reclaim time to focus on strategic rate negotiations.

Beginner’s Action Checklist: Your First 30 Days

Week 1: Audit your current shipping spend. Pull 100 recent orders and calculate your average cost-per-shipment by carrier, destination, and weight category. Be honest about what you’re paying.

Week 2: Request rate quotes from at least three carriers (or consolidators if you’re shipping internationally). Include your typical volume projections. Compare not just headline rates but also dimensional weight formulas, fuel surcharges, and hidden fees.

Week 3: Test at least one alternative carrier or service on a small batch (10-20 orders). Track delivery times, customer feedback, and total cost.

Week 4: Implement one quick win—whether that’s rightsizing packaging, switching to a bulk platform, or integrating a shipping API. Measure the impact.

Beginner goal: Reduce shipping costs by 8-12% within 60 days.

Advanced User Roadmap: Scaling Beyond Basics

If you’re already optimized on the fundamentals, here’s where real competitive advantage emerges:

Carrier Negotiation Strategy: Build a data dashboard tracking your negotiating leverage—monthly volume, growth rate, customer satisfaction scores. Use this to secure customized rates beyond published pricing. I’ve seen mid-sized e-commerce operations unlock 15-20% reductions through direct negotiations.

Regional Arbitrage & Pooling: Establish micro-fulfillment hubs in key markets (US, EU, Asia-Pacific). Ship inventory in bulk via cheapest way to ship a package internationally, then handle last-mile domestically. This dramatically compresses per-unit costs.

Predictive Analytics Integration: Use historical shipment data to forecast seasonal surges. Lock in rates during off-peak periods. Adjust inventory positioning months in advance.

Sustainability as Cost Driver: Optimize for lighter packaging and consolidated shipments not just for cost, but because carriers are increasingly incentivizing eco-friendly practices with rate credits.

Advanced goal: Achieve 20-30% cost reduction while maintaining or improving delivery speed and customer satisfaction.

Essential Tools & Platforms for Ongoing Optimization

– Shipping Management Platforms: Shippo, ShipStation, or EasyPost integrate multiple carriers, compare rates in real-time, and provide robust analytics.

– Rate Intelligence: Leverage tools like Parcel Monitor to track carrier pricing trends and identify rate increase patterns.

– Cost Benchmarking: Join industry peer groups or use platforms like Inbound Logistics to benchmark your metrics against competitors.

Continuous Learning & Support

The shipping landscape changes monthly—new rate structures, carrier partnerships, regulatory requirements. Stay ahead by subscribing to industry newsletters like Logistics Manager’s Journal or Supply Chain Dive. Attend quarterly webinars on emerging fulfillment trends.

Where to Get Help When You’re Stuck

That’s where we come in. At ASG, our dedicated logistics team doesn’t just process your orders—we actively hunt for cost optimizations specific to your business. Whether you need help calculating the cheapest way to ship a package to a new market, renegotiating carrier terms, or redesigning your fulfillment strategy, reach out to our team. We’ve helped hundreds of sellers reduce shipping costs by an average of 16% in their first 90 days.

Your competitive edge isn’t hidden. It’s waiting in the details of your supply chain.