Let’s be honest: receiving a return notification is the single most frustrating part of being a dropshipper. You’ve spent hours on marketing and product research, only to see your hard-earned profit vanish because of a damaged item or a customer’s change of heart. In 2023 alone, returns cost U.S. retailers over $248 billion, and as e-commerce grows, that number is only climbing. If you don’t have a bulletproof system for handling these requests, you aren’t just losing money on one sale—你 are risking your payment processor’s health and your brand’s reputation.

In this guide, I’m pulling back the curtain on how we handle returns at ASG Dropshipping for over 6,000 clients. You will learn how to turn a logistical nightmare into a customer loyalty engine. We aren’t just talking about ‘giving money back’; we are talking about Return Merchandise Authorizations (RMA), returnless refunds, and how to negotiate with suppliers so you never pay for their mistakes. Whether you are a Shopify beginner or a scaling pro, this is the framework you need to safeguard your margins in 2026.

Key takeaways

- Average e-commerce return rates hover between 20-30%, necessitating a pre-planned financial buffer.

- Always verify product defects with photos/videos before initiating any supplier dispute.

- Utilizing Return Merchandise Authorization (RMA) is critical for tracking and validating international returns.

- Returnless refunds are often more profitable for low-cost items than paying for reverse logistics.

- A transparent, easy-to-find return policy can actually increase conversion rates by building trust.

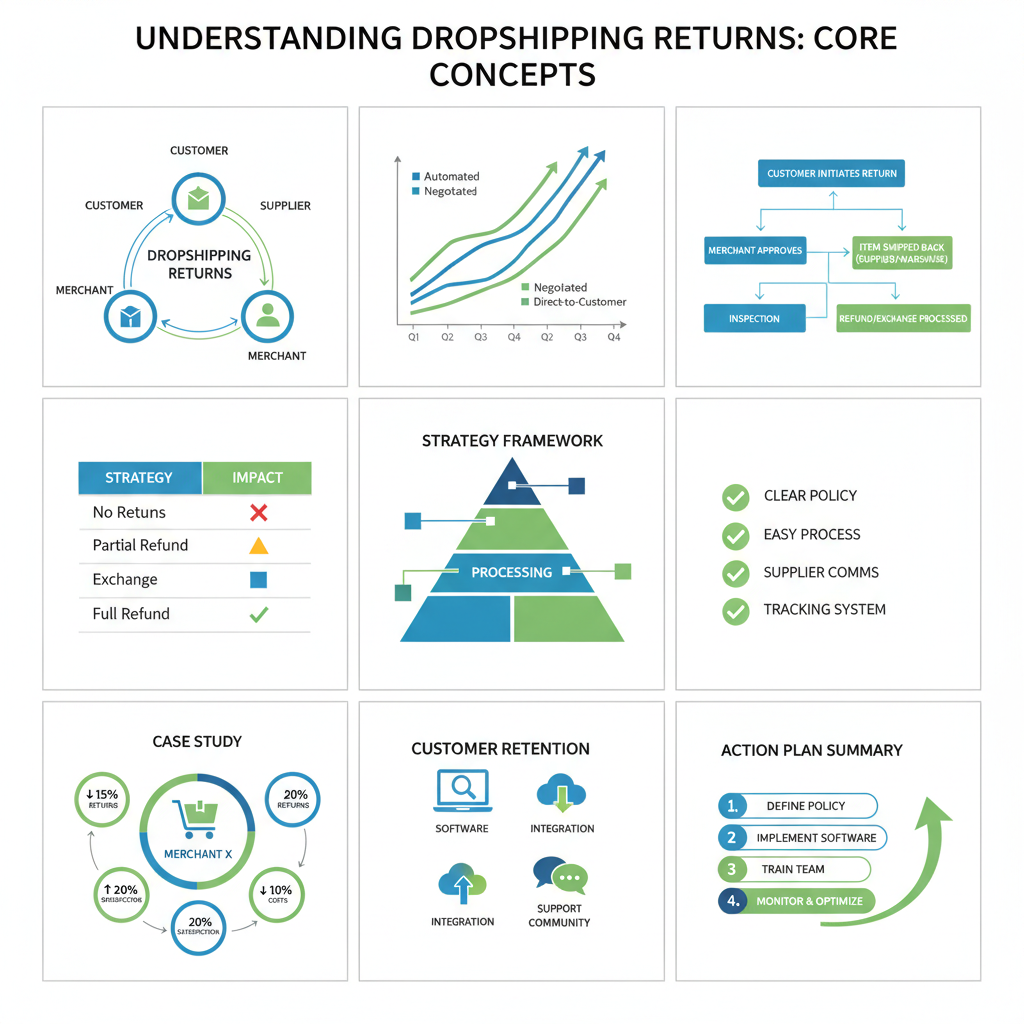

Understanding Dropshipping Returns: Core Concepts

Understanding Dropshipping Returns: Core Concepts – Visual Guide

Understanding Dropshipping Returns: Core Concepts – Visual Guide

At its core, a dropshipping return is a three-way coordination dance between the customer, you (the retailer), and the third-party supplier. Unlike traditional retail, you don’t have the luxury of inspecting the item yourself. According to sellthetrend.com, returns are generally triggered by damaged goods, shipping delays, or ‘buyer’s remorse.’ Understanding these triggers is the first step in building a defense.

There are two main paths a return can take: the physical return of the item to the supplier or a refund without a return. The latter, often called a ‘returnless refund,’ is a strategic move used when the cost of shipping the item back to China or a local warehouse exceeds the value of the product itself. In 2025, many smart sellers are adopting this to maintain high customer satisfaction scores.

Another vital concept is the RMA (Return Merchandise Authorization). This is a numbered authorization provided by the supplier that must be included with the returned package. Without an RMA, your supplier’s warehouse might reject the package, leaving you responsible for the refund without any recourse. As noted by zik analytics, using an RMA ensures smoother handling and protects your business margins from unverified claims.

Finally, you must distinguish between ‘defective’ returns and ‘preference’ returns. If a product is broken, the supplier should foot the bill. If the customer simply changed their mind, your policy needs to dictate who covers the return shipping—usually the customer. Clearly defining these categories in your internal SOPs prevents confusion when a case hits your inbox.

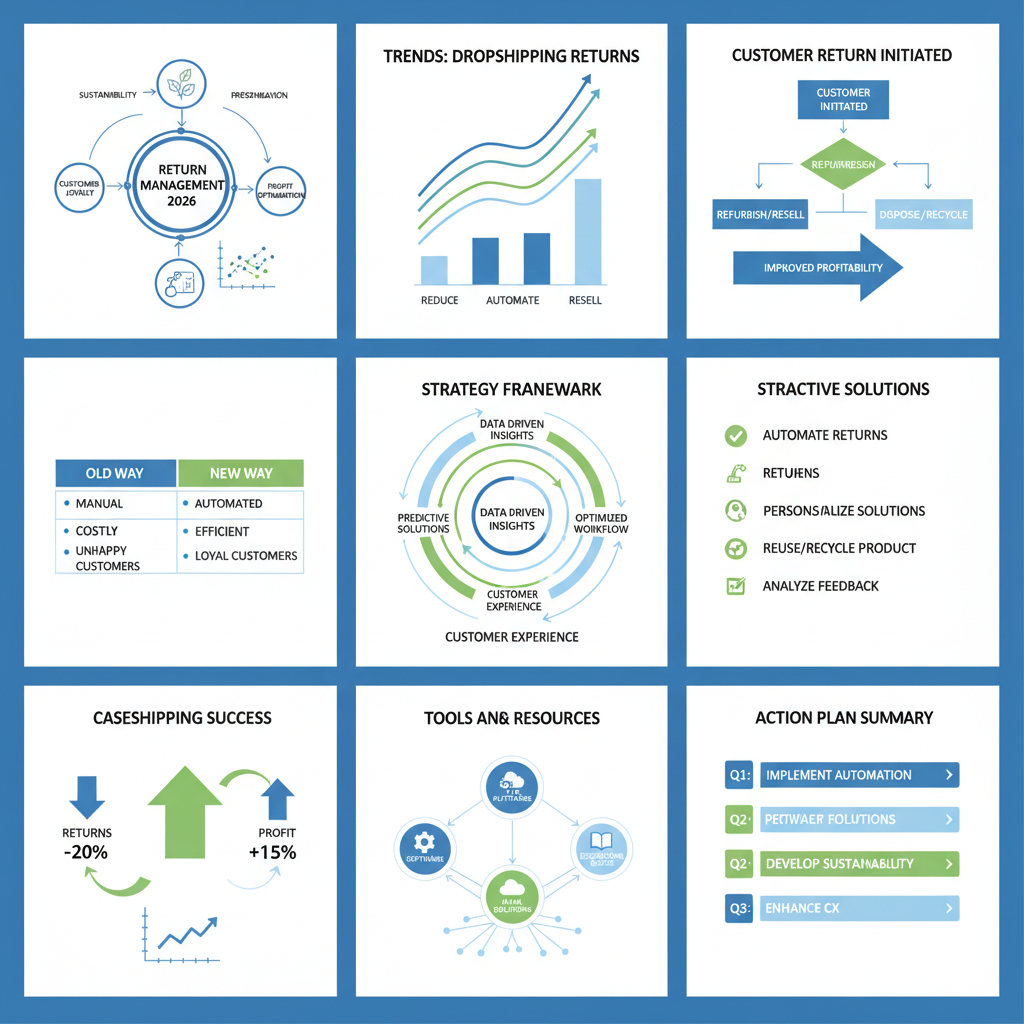

Why Return Management Matters in 2026: Trends & Data

Why Return Management Matters in 2026: Trends & Data – Visual Guide

Why Return Management Matters in 2026: Trends & Data – Visual Guide

In 2026, customer expectations have reached an all-time high. Data from dropshipping.com suggests that the average e-commerce return rate is now around 18%, but for fashion and apparel, it can peak as high as 30%. If you aren’t accounting for these numbers in your pricing strategy, you are effectively operating at a loss.

| Industry Segment |

Average Return Rate |

Primary Reason for Return |

| Electronics |

10-12% |

Technical Malfunction |

| Fashion & Apparel |

25-30% |

Sizing/Fit Issues |

| Home Decor |

8-10% |

Item Not as Described |

| Pet Supplies |

5-7% |

Compatibility Issues |

Beyond just the immediate loss of a sale, poor return handling leads to ‘adverse signals’ to payment gateways like Stripe or PayPal. High refund rates can trigger account reserves or even permanent bans. dariomarkovic.com highlights that over 30% of all online purchases now end in a return, making professional management a requirement for legal and financial compliance.

Furthermore, the ‘sustainability’ trend in 2026 is changing how we view reverse logistics. Customers are becoming more aware of the carbon footprint of shipping items back and forth. Offering a discount on a future purchase instead of a full return can sometimes satisfy a customer while saving the environment and your profit. This proactive approach turns a negative experience into a brand-building moment.

Implementation Strategies: Practical Action Steps

When a return request arrives, your first action should be empathy, followed immediately by evidence gathering. I always tell my team: ‘Never refund without a photo.’ Ask the customer for a clear photo or video of the defect. This isn’t just to catch scammers; it’s the ‘ammunition’ you need to get a refund from your supplier.

Once you have proof, follow this 4-step workflow: 1) Apologize and validate the customer’s concern. 2) Determine if the item is worth shipping back. 3) If yes, secure an RMA from your supplier. 4) If no, issue a returnless refund or a replacement. dropshipzone.com.au emphasizes that even though returns result in revenue losses, refusing them altogether is the fastest way to kill your store’s reputation.

For international dropshipping, consider using a local return hub. At ASG, we provide our clients with access to warehouses in major markets like the US and EU. Instead of shipping a $20 item back to China for $30, the customer ships it to our local hub for $5. We verify the condition and then you can choose to resell it or dispose of it. This significantly reduces the ‘burn rate’ associated with international logistics.

Automation is your best friend here. Use Shopify apps like AfterShip Returns or Loop to create a self-service return portal. This reduces the workload on your customer support team and gives the customer a sense of control. According to sellthetrend.com, keeping your return policy up-to-date and easily accessible is one of the best practices for reducing friction and protecting your time.

Common Mistakes to Avoid: Lessons from the Trenches

The biggest mistake I see new dropshippers make is having a ‘No Returns’ policy. While it sounds like it protects your money, it actually invites chargebacks. When a customer feels trapped, they go to their bank. A chargeback costs you the sale, the shipping, and a $15-$25 penalty fee. It is always cheaper to refund than to lose a chargeback dispute.

Another fatal error is not aligning your store’s policy with your supplier’s policy. If your supplier only offers a 15-day return window but you promise 30 days, you are liable for those extra 15 days out of your own pocket. dropshipping.com warns that you must adapt your terms to your backend logistics to avoid significant financial leaks.

Failing to account for shipping costs in the return process is a third common pitfall. Many sellers forget to specify who pays for the return label. If your policy is vague, customers will expect you to pay. In 2026, 75% of customers expect free returns, but for a low-margin dropshipping store, this can be unsustainable. Be explicit: ‘Free returns for defects; customer pays for change of mind.’

Lastly, don’t ignore the ‘Serial Returners.’ Some customers buy five items with the intent of returning four. Use data analytics to flag these users and potentially block them from future purchases. Protecting your business means knowing when to say no to a toxic customer relationship before it drains your resources.

Pro Tips from Janson: CEO Insider Insights

After overseeing thousands of shipments at ASG, I’ve learned that the best return strategy is a ‘Prevention First’ strategy. Most returns happen because the customer’s expectation didn’t match the reality. We found that adding a simple 15-second smartphone video of the product to the Shopify page reduced return requests by 22% for our top-tier sellers.

Another ‘CEO secret’ is the ‘Partial Refund’ offer. If a customer complains about a minor scratch or a slight color variance, offer them a 30% partial refund to keep the item. Most customers will take the cash, and you save on the shipping costs and the hassle of a full return. This is a win-win that dariomarkovic.com suggests can significantly preserve your profit margins.

Leverage your supplier relationships. If you are doing significant volume, don’t just accept their standard policy. Negotiate a ‘Monthly Refund Credit.’ For example, ask for 2% of your total monthly spend to be credited back to cover any defective items, no questions asked. This eliminates the need to argue over every single $10 item and keeps your workflow moving fast.

Finally, always use ‘Tracked Returns.’ Never allow a customer to send an item back via a non-tracked service. If the package goes missing, you are stuck in a ‘he-said, she-said’ situation. Insisting on tracking—and providing the label yourself via a platform like Pirate Ship—gives you the data needed to finalize the refund with confidence.

Key Takeaways & Next Steps: Your Action Plan

Managing returns doesn’t have to be the death of your business. By implementing a structured RMA process and being transparent with your customers, you can actually improve your brand’s standing. zikanalytics.com points out that excellent customer service during the return process is the key to preventing negative reviews and building long-term trust.

Your immediate action plan should be: 1) Audit your current return policy to ensure it matches your supplier’s terms. 2) Create a ‘Returns’ page on your website that is easy to find in the footer. 3) Set up a dedicated ‘Returns’ folder in your customer support email to track every request. 4) Start requesting photos for every claim to build a library of evidence for your suppliers.

Remember, a return is just an opportunity to show your customer that you are a real, professional brand. If you handle it with grace and speed, they are much more likely to come back and buy something else. Statistics show that customers who have a positive return experience are 70% more likely to become repeat buyers.

At ASG Dropshipping, we handle the heavy lifting of inspections and local warehousing so you can focus on scaling. If you’re tired of the return headache, it might be time to switch to an agent that prioritizes your post-purchase experience as much as your sales. Let’s make 2026 the year your margins stay protected.

Sources and further reading (selected)

- Sell The Trend: A comprehensive 2025 guide on managing dropshipping refunds and the cost of returns to retailers. Read more →

- Dropshipping.com: Expert analysis of 2025 return rates and strategies for Shopify store owners. Read more →

- Dropshipzone: A detailed 5-step process for handling returns from an Australian logistics perspective. Read more →

- Dario Markovic: E-commerce strategy guide focused on maximizing profit margins despite high return rates. Read more →

- ZIK Analytics: A professional guide on handling returns for eBay and Shopify dropshippers. Read more →

- Shopify Blog: Official Shopify resources for setting up automated return systems. Read more →

- Statista: Source for global e-commerce return statistics and consumer behavior data. Read more →

- National Retail Federation: Data on the economic impact of retail returns in the United States. Read more →

- USPS Business: Logistics information regarding domestic return shipping labels and tracking. Read more →

- PayPal Merchant Support: Guidelines on managing disputes and refunds to maintain account health. Read more →