China warehouse services provide global sellers with strategic localized storage, efficient quality control, and streamlined fulfillment capabilities directly from the world’s largest manufacturing hub. By utilizing a domestic facility in China, businesses can consolidate products from multiple suppliers, conduct rigorous inspections before international dispatch, and significantly reduce shipping costs through bulk logistics. Mastering these operations is the cornerstone of a successful cross-border supply chain, as it allows entrepreneurs to minimize lead times and ensure product quality before the final leg of delivery.

China warehouse FAQs are among the most searched topics by global ecommerce entrepreneurs. As ASG’s CEO with years in cross-border trade, I’ve compiled the definitive guide to help you navigate China’s complex warehouse landscape. Many users are concerned about china-warehouse-faqs, and this article systematically covers warehouse selection, cost analysis, legal compliance, and operational best practices to ensure your business thrives. For those tracking specific statuses, understanding what is international warehouse shein can provide useful context on how major players manage these nodes.

Strategic Insights into China’s Logistics Ecosystem

Navigating China’s warehouse ecosystem can feel overwhelming. I remember when I first started ASG drop shipping, the sheer volume of questions about Chinese warehouses almost paralyzed our decision-making. The truth is, China’s warehouse industry has evolved dramatically, with average rents at 43% below global benchmarks and specialized facilities catering to every business need. To see how these facilities operate in the modern market, check out our international warehouse Shein complete 2026 shipping guide for a deep dive into future logistics trends.

In this comprehensive guide, I’ll share everything I’ve learned from working with 2300+ factory warehouses across China. We’ll cover everything from basic operational questions to complex legal requirements like the international emergency economic powers act. You’ll learn how to handle withdrawn from warehouse scenarios, understand ISO country code CN implications, and master the logistics that make or break your cross-border success.

Whether you’re testing products or scaling operations, understanding China warehouse FAQs is your competitive advantage. Let’s dive into the 25 most critical questions that every serious ecommerce entrepreneur needs answered.

The following list extracts the primary section headings from this guide, which addresses the critical operational questions regarding China-based fulfillment, costs, and international trade compliance for e-commerce entrepreneurs.

1. China Warehouse Costs & Rent Analysis

2. Legal Compliance & Import Regulations

3. Warehouse Selection Best Practices

4. Logistics & Supply Chain Management

5. Iso country code cn

6. China-warehouse-faqs

China-warehouse-faqs

Dropshipping 101: A Founder’s Guide to the Modern Retail Model

Let’s cut through the noise. Over the years, I’ve seen countless aspiring sellers jump into dropshipping with more enthusiasm than understanding. They get lured by the “easy money” narrative and often crash because they don’t grasp the fundamentals. Think of this section as your foundational blueprint. We’re not just defining a term; we’re unpacking the operational reality of what makes or breaks a dropshipping business today. It’s the difference between building on sand and laying a concrete foundation.

What Exactly Is Dropshipping? (It’s Not Magic)

In the simplest terms, dropshipping is a retail fulfillment method where you, the store owner, sell products without ever handling the inventory. When a customer places an order on your store, you forward that order and shipping details to a third-party supplier (like ASG). We then package and ship the product directly to your customer. You never see or touch the product.

The key distinction from traditional retail is inventory risk. In a classic model, you buy stock upfront, hoping it sells. If it doesn’t, you’re stuck with it. Dropshipping flips this: you only purchase an item after you’ve already sold it and been paid by the customer. This dramatically lowers the barrier to entry and financial risk, which is why it’s so attractive to entrepreneurs. However, this “hands-off” nature is also its biggest challenge, placing immense importance on your choice of supplier for quality, speed, and reliability.

How It Actually Works: The Nuts and Bolts

Many guides make this sound like a three-click process. In reality, a smooth operation requires a well-oiled system. Here’s the workflow I’ve optimized at ASG for our partners:

1. You List & Market: You add a product from your supplier’s catalog (like ours) to your online store (Shopify, WooCommerce, etc.). You set your retail price.

2. Customer Orders: A customer buys from your store at your marked-up price.

3. You Place the Backend Order: You receive the order and payment. You then place the order with your supplier (us), paying the wholesale cost and providing the customer’s shipping address.

4. Supplier Fulfills: This is where the rubber meets the road. A reliable supplier (like ASG) receives your order, picks, packs, and ships the product directly to your customer. We handle all the logistics.

5. Tracking & Updates: The supplier provides a tracking number, which you should forward to your customer. Transparency here builds trust.

6. You Handle Customer Service: Any post-purchase questions or issues come to you. You then liaise with your supplier to resolve them.

The smoother steps 3-5 are, the more scalable your business becomes. This is why we built our proprietary Shopify App and ERP system—to automate this flow and turn days of manual work into minutes.

Why Dropshipping is More Important Than Ever

You might think, “Isn’t this model old news?” On the contrary, its strategic importance has only grown. The global e-commerce boom, accelerated by recent years, has created a massive demand for agile, low-risk retail models. A report by Grand View Research projects the global dropshipping market to reach $1.2 trillion by 2030, growing at a compound annual growth rate (CAGR) of over 23% from 2023 Grand View Research.

For you, the seller, its importance boils down to three core advantages I see our successful clients leverage:

Unmatched Agility: You can test products, niches, and marketing angles with near-zero financial commitment. A product not selling? Remove it instantly. No dead stock.

Scalability: Since you’re not managing a warehouse, scaling up doesn’t mean exponentially more physical work. Your supplier’s infrastructure (like our network of china warehouse FAQs-ready facilities) bears the burden.

Focus on Core Competencies: You can pour your energy and capital into what truly moves the needle: branding, marketing, and customer experience. Let experts like us handle the complex procurement, china warehouse FAQs, and logistics.

The Two Main Flavors of Dropshipping

Not all dropshipping is created equal. Based on my experience, there are two primary models, and choosing the right one is critical:

1. General/Marketplace Dropshipping: Sourcing from massive open platforms like AliExpress. It’s incredibly easy to start. However, the trade-offs are severe: longer shipping times (often 15-40 days), extreme product commoditization (everyone sells the same thing), inconsistent quality, and virtually no brand control. It’s a race to the bottom on price.

2. Specialized/Partner Dropshipping (The ASG Model): Partnering with a dedicated agent or supplier who acts as your extension in the sourcing market. We don’t just list products; we procure them from our vetted network of over 2,300 factories. This model offers faster shipping (we average 6-10 days to major markets), better pricing through direct relationships, quality control, and white-label/branding services. The goal here isn’t just to sell a product; it’s to build a brand with a reliable back-end.

Key Elements of a Viable Dropshipping Business

Forget the “get-rich-quick” checklist. Here are the non-negotiable pillars I advise every new partner to secure before spending a dollar on ads:

| Element |

Why It’s Critical |

The Common Pitfall |

| A Reliable Supplier |

Your entire customer experience hinges on them. They control product quality, shipping speed, and issue resolution. |

Choosing based on lowest price alone. This leads to shipping nightmares and angry customers. |

| A Solid Niche |

You can’t sell everything to everyone. A focused niche allows for targeted marketing and builds authority. |

Jumping on every “viral” product trend without a cohesive strategy. |

| Customer Service Plan |

You are the face of the business. How you handle problems defines your brand’s reputation. |

Assuming “no inventory” means “no service.” This is a fast track to chargebacks and failed stores. |

| Understanding Margins |

You must account for product cost, shipping, payment gateway fees, marketing costs, and your time. |

Using simple “2x markup” rules without calculating all actual costs, leading to zero profit. |

| Marketing & Traffic Strategy |

Even the best store is useless without visitors. You need a plan to attract and convert customers. |

Relying solely on one unstable channel (e.g., a single TikTok trend). |

Busting Common Dropshipping Misconceptions

Let me set the record straight on a few myths I hear daily:

Misconception 1: “It’s completely passive income.” False. It’s a leveraged business model. The initial setup and ongoing marketing, customer service, and supplier management require significant work. The “passive” part is not managing a warehouse.

Misconception 2: “You don’t need any money to start.” Partially true, but dangerously simplistic. While you don’t need inventory capital, you do need funds for your store platform, apps, marketing/ad spend, and a buffer for operational costs. Trying to start with $0 is a recipe for failure.

Misconception 3: “The supplier handles everything, so I’m risk-free.” The operational risk of inventory is gone, but the brand risk is 100% yours. If your supplier sends a defective product, your customer is disappointed, your store gets the bad review, and you are responsible for making it right. This is why our china warehouse FAQs and quality checks are so stringent—we protect your brand as if it were our own.

Misconception 4: “It’s all about finding a winning product.” This is a short-term game. The real, sustainable winners I’ve seen are those who use winning products as an entry point to build a recognizable brand with a loyal audience. That’s where the true long-term value lies.

Understanding these fundamentals is your first step. The next step is finding a partner who not only understands them but has built systems—like our integrated platform and china warehouse FAQs-addressed logistics network—specifically to navigate these challenges and turn this model into a real, scalable business for you.

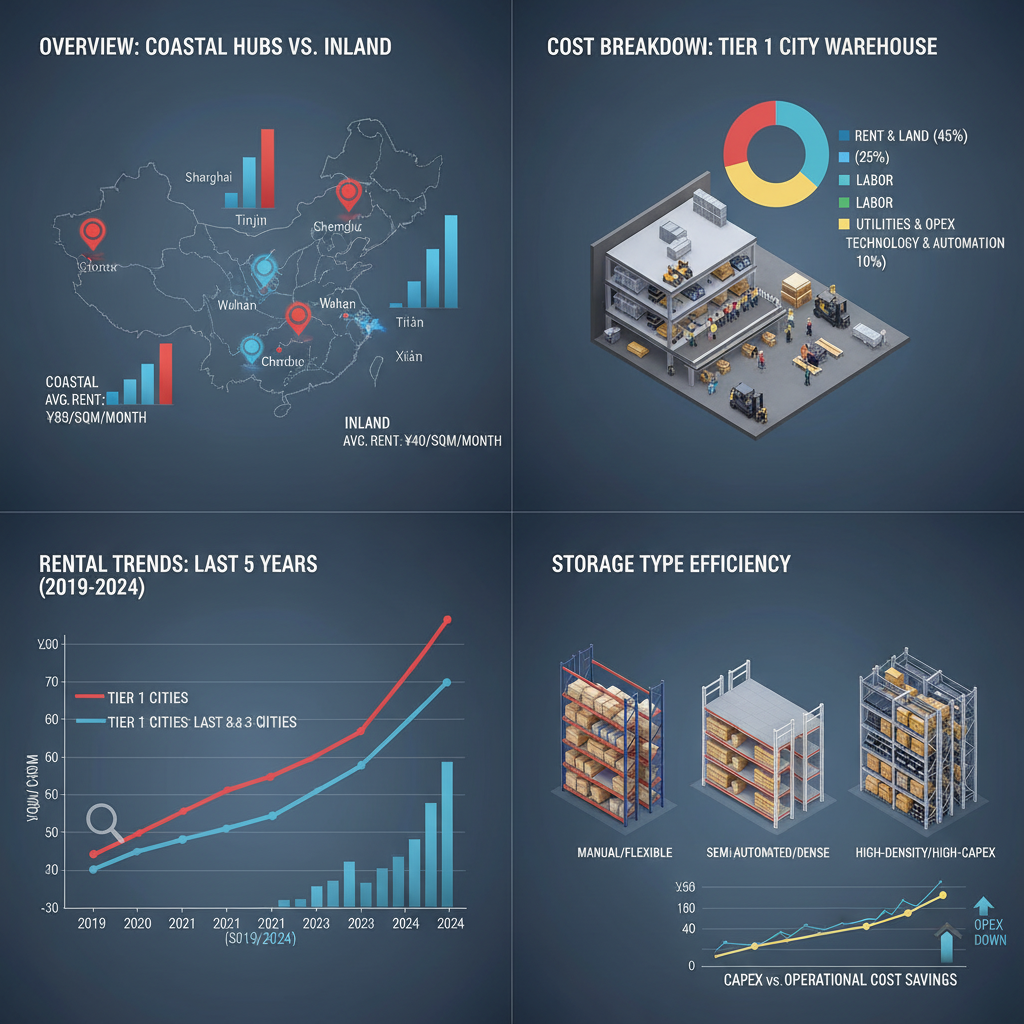

China Warehouse Costs & Rent Analysis

The Real Deal on China Warehouse Partnerships: A CEO’s Playbook

Let’s get straight to the point. After two decades in this game, I’ve seen more dropshipping businesses succeed or fail based on their warehouse partnership than on their marketing. It’s the unsexy, back-end engine that either drives you to profit or grinds you to a halt. Many sellers focus on the front-end—the ads, the website, the branding. That’s important. But the real magic, the real moat you build, happens in the logistics chain. A great china-warehouse-faqs list answers the “what,” but I want to give you the “how” and “why.”

Choosing a China warehouse partner isn’t just about finding a place to store boxes. It’s about integrating a core component of your operational brain. Get it wrong, and you’re dealing with delayed shipments, wrong items, stockouts, and customer service nightmares that erode your brand faster than any bad review. Get it right, and you unlock scalability, reliability, and peace of mind.

Here’s my detailed breakdown of what you need to know, from the common pitfalls to the winning strategies.

The Core Problem: Why Most Sellers Get This Wrong

Most new sellers approach a China warehouse like they’re renting a storage locker. They look at price per cubic meter and location. That’s a recipe for disaster. The real challenge is the operational handshake between your virtual store and their physical space. You’re not just storing goods; you’re entrusting them with your customer experience.

I’ve seen businesses fail because their warehouse couldn’t handle a 300% order spike during Black Friday. I’ve seen others bleed money because of poor inventory tracking leading to constant overselling. The problem isn’t the warehouse itself; it’s the mismatch between your business’s needs and the warehouse’s capabilities. You need a partner that acts as an extension of your team, not just a vendor.

A Deep Dive: The Four Pillars of a Successful Warehouse Partnership

Think of your warehouse relationship as a stool. It needs four solid legs to stand.

Leg 1: Technology & Integration. Can their system talk to your Shopify store seamlessly? At ASG, our entire model is built on this. Our custom app and API ensure that when an order hits your store, it’s instantly in our system for picking. No manual CSV uploads, no email chains. This real-time sync prevents overselling and provides instant tracking updates to your customer. A 2023 study by Gartner found that businesses with deeply integrated supply chain tech saw a 35% reduction in fulfillment errors. That’s the power of proper integration.

Leg 2: Process & Communication. What’s their standard operating procedure (SOP) for receiving your goods, quality checks, picking, packing, and shipping? How do they communicate errors? We enforce a “no surprises” rule. If a product arrives damaged from the factory, our team flags it immediately with photos before it hits the shelf. This proactive communication saves weeks of potential headaches down the line.

Leg 3: Scalability & Flexibility. Your partner must grow with you. Can they handle 10 orders a day? What about 1,000? Do they offer flexible storage plans, or lock you into rigid contracts? We designed our china-warehouse-faqs to address this directly, offering scalable solutions because I remember the pain of outgrowing a provider mid-season.

Leg 4: Value-Added Services. This is the differentiator. Basic storage is a commodity. Look for partners who offer services that elevate your brand. For us, that’s our white-label packaging, custom thank-you cards, and kitting services. A McKinsey report on e-logistics highlights that “service differentiation” is now a key battleground for 3PLs. It turns a cost center into a brand-building asset.

Strategic Playbook: Matching Your Stage with the Right Solution

Your needs at 10 orders a week are different from 1,000. Here’s my tactical advice.

Scenario A: The Testing Phase (0-20 orders/week).

You’re validating products. Don’t commit to long-term storage. Use a partner like ASG that offers “virtual warehousing” or consolidated shipping. We let you test up to 5 products with a low MOQ. The goal here isn’t cost optimization; it’s speed and reliability of data. Focus on partners who give you detailed inspection videos and fast turnaround for samples.

Scenario B: The Scaling Phase (20-200 orders/week).

Consistency is king. You need a dedicated account manager and predictable processes. Now is the time to negotiate better rates based on volume. Look for warehouses with robust ERP systems that give you real-time inventory dashboards. This is where our china-warehouse-faqs become critical—asking about their tech stack and reporting capabilities is non-negotiable.

Scenario C: The Brand-Building Phase (200+ orders/week).

Your brand reputation is on the line with every package. You need a strategic partner, not just a supplier. Prioritize warehouses that offer advanced services: custom packaging integration, advanced QC processes, and multi-channel fulfillment (direct-to-consumer and wholesale). At this stage, the cost per unit matters less than the total value delivered to your end customer.

The Four Non-Negotiables for Success

Based on managing millions of orders, here are my four absolute must-haves:

1. Real-Time, Two-Way Inventory Sync: Your store’s stock levels must be their command. Any delay causes overselling.

2. Transparent, Item-Level QC: You must receive photos/videos of random samples from each batch received. Trust, but verify.

3. Clear SLAs (Service Level Agreements): Get in writing their order processing time (ours is 1-3 days), their error rate tolerance, and their communication protocols for issues.

4. Financial Stability & Longevity: Do a background check. How long have they been in business? Are they financially sound? The last thing you need is your inventory held hostage by a bankrupt partner.

Time & Cost Analysis: What You’re Really Paying For

Don’t just look at the storage fee. Here’s a breakdown of the true costs and time sinks.

| Cost/Time Factor |

Cheap/DIY Warehouse |

Integrated Partner (e.g., ASG) |

The Real Impact |

| Monthly Storage Fee |

Lower ($/cbm) |

Slightly Higher |

Cheap wins on paper. |

| Order Processing Time |

5-7+ days (manual) |

1-3 days (automated) |

Partner wins. Faster delivery = higher customer satisfaction & repeat buys. |

| Error Rate & Returns |

High (5%+) |

Low (<1% with good partners) |

Partner wins. Errors destroy margin and brand trust. |

| Your Management Time |

10-15 hrs/week |

1-2 hrs/week (monitoring) |

Partner wins. Your time is your most valuable asset. Focus on growth. |

| Hidden Costs |

Label printing, packing materials, software subscriptions, QA labor. |

Often bundled. |

Partner wins. Predictable, all-in cost. |

| Scalability Cost |

High (hiring, training, new contracts). |

Low (scaled within existing agreement). |

Partner wins. Smooth growth without operational cliffs. |

The math is clear. The “cheaper” option often has a much higher total cost of ownership when you factor in your time, errors, and lost sales from slow shipping.

Navigating Common Pitfalls: My Pro-Tips

Pitfall: “They said they had the stock, but they didn’t.”

Countermeasure: Insist on live inventory data linked to your platform. Never rely on “yes, we have it” in an email. Our system shows you live counts.

Pitfall: “My shipment was returned due to customs issues.”

Countermeasure: Your warehouse must be an expert in your target market’s regulations. They should handle commercial invoices, HS codes, and know restricted items. This is a core part of our china-warehouse-faqs and onboarding.

Pitfall: “Communication is slow, and issues take days to resolve.”

Countermeasure: Demand a dedicated contact (like our 1-on-1 agents) and agreed-upon response times (e.g., 4 hours for urgent issues). Use communication tools like Slack or WhatsApp groups for immediacy.

Pitfall: “The quality of the packed items is inconsistent.”

Countermeasure: Set a clear, photographic packing standard. Conduct periodic “mystery shopper” orders to your own address to audit the unboxing experience.

The Bottom Line: It’s About Partnership, Not Procurement

After all these years, my best advice is this: view your china-warehouse-faqs not as a list of transactional questions, but as a filter for finding a true partner. You’re looking for reliability, transparency, and a shared goal of making your customer happy.

The right partner becomes a force multiplier. They give you the confidence to run ads aggressively, knowing the backend won’t collapse. They provide the data to make smarter inventory decisions. They deliver the unboxing experience that turns a one-time buyer into a fan.

At ASG, we built our service because I needed this partner and couldn’t find one that ticked all the boxes. So we became it. Whether you work with us or another provider, use this framework. Dig deep, ask the hard questions, and choose based on capability, not just cost. Your future scaled-up business will thank you for it.

Legal Compliance & Import Regulations

Navigating the Operational Backbone: Tech, Strategy, and Precision

Building a successful dropshipping business is more than just finding a hot product. It’s about building a robust, scalable, and intelligent operational engine. Over the years at ASG, I’ve seen brilliant product ideas fail due to clunky backend operations, and modest products thrive because of a seamless, tech-driven fulfillment system. This section is where we move from the “what” to the “how,” diving into the strategic and technological core that separates hobbyists from serious entrepreneurs.

The Strategic Mindset: Beyond Just Selling Products

Many new sellers jump straight into product research, but I always advise starting with an operational strategy. Your strategy is your roadmap; it dictates your tool choices, your workflow, and ultimately, your scalability. The core question is: Are you building a brand or just testing products? If it’s the former, your strategy must include branded packaging, custom inserts, and a plan for customer loyalty from day one. This influences your supplier choice (like ASG, which offers these services natively) and your tech stack.

For testers, the strategy is speed and data. You need a system that lets you launch, test, and kill products with minimal friction. This means prioritizing suppliers with low MOQs (we offer a 5-order test batch), fast processing times (our 1-3 day target), and transparent data flow. Your operational goal here is to minimize the time and cost per test cycle. A study by the Harvard Business Review on agile business practices highlights that rapid iteration cycles, enabled by flexible supply chains, significantly increase the odds of finding a winning product Harvard Business Review. Your china-warehouse-faqs should always address how quickly you can pivot, which is a direct function of your operational strategy.

The Technology Stack: Automating for Scale and Sanity

Manual order processing is the single biggest growth killer in dropshipping. Once you hit 10+ orders a day, you need automation. Our philosophy at ASG was to build our entire service around this principle. The cornerstone is a seamless integration between your store and your supplier. For Shopify users, our dedicated app is a game-changer—it automates order forwarding, tracking sync, and inventory updates.

But technology isn’t just about apps. It’s about systems. We use a sophisticated ERP that connects directly to our network of over 2300 factory warehouses. When your order comes in, it’s not just an email; it’s a digital work order that routes instantly to the optimal fulfillment node based on product, destination, and cost. This is what allows us to promise 1-3 day processing. For sellers not on Shopify, we leverage automated Google Sheets workflows that mimic this process, ensuring no one is left out of the efficiency loop. Investing in the right tech stack from the beginning saves you from a world of copy-paste errors and customer service nightmares.

Innovation in Fulfillment: Not Just Faster, But Smarter

Innovation in our space isn’t always about new gadgets; it’s about smarter processes. One innovation we’re proud of is our proactive QC video system. During the testing phase, instead of just sending a sample, we send a video of our agent inspecting your specific unit in the china warehouse. This pre-empts a huge chunk of post-purchase issues. Another is our dynamic logistics routing. We don’t have a one-size-fits-all shipping line. Our system analyzes destination, package dimensions, and current carrier performance to select the most reliable and cost-effective route, which is why we consistently hit that 6-10 day global delivery window, especially to the US and EU.

We also innovated on the branding side with on-demand printing. Traditionally, custom packaging required huge minimums. Now, we can insert branded thank-you cards or even print minimal branding on packages for much smaller runs, making brand-building accessible from the very first order. This turns a generic parcel into a brand touchpoint.

Advanced Optimization: Squeezing Margin and Boosting Satisfaction

Once the basics are running, optimization is how you win. Here are my pro-tips:

Bundle Analytics: Use your sales data to identify frequently co-purchased items. Work with your agent to create a custom bundle SKU. This reduces per-item shipping costs and increases average order value.

Strategic Warehousing: Don’t just think “China.” For best-selling products, discuss with your agent (like your ASG manager) the feasibility of holding small inventory in a destination-country warehouse. Even a 3PL in the US for your top 3 products can slash delivery times from 10 days to 2, dramatically boosting conversions and reviews.

Communication Triggers: Automate post-purchase emails with integrated tracking. But go further: set a trigger for packages that haven’t updated tracking in 5 days. Proactively reach out to your agent to investigate before the customer complains. This level of service builds immense trust.

Comparative Analysis: DIY Sourcing vs. Integrated Agents like ASG

Let’s break down the two main paths:

DIY Sourcing (AliExpress, 1688 Direct):

Pros: Maximum theoretical margin per item; direct factory contact.

Cons: Extremely high time cost for communication, QC, and dispute resolution; fragmented logistics; no brand support; high risk of quality inconsistency; scaling is a logistical nightmare.

Integrated Fulfillment Agent (e.g., ASG):

Pros: Turnkey automation; consolidated QC and logistics; built-in branding options; dedicated support for problem-solving; designed for scaling.

Cons: Margin per item is slightly lower to account for the service layer.

The analysis is clear for anyone serious about growth. DIY is a full-time job in supply chain management. Using an agent is a force multiplier. Your job becomes marketing and customer acquisition, while experts handle the operations. The ROI on your time almost always favors the agent model once your volume exceeds a handful of daily orders.

Essential Tools & Resources for the Modern Seller

Beyond your supplier’s tech, arm yourself with these:

Analytics: Google Analytics 4 and your platform’s native analytics are non-negotiable. Track acquisition cost and customer lifetime value religiously.

SEO & Content: Ahrefs or Semrush for keyword research. For content, look at AnswerThePublic to find customer questions.

Creative: Canva Pro for quick ad creatives and social media assets.

Communication & Project Management: Slack or Discord for internal teams; Trello or Asana to manage product launches and marketing campaigns. With ASG, you get a dedicated agent on WhatsApp for instant operational comms.

Financials: QuickBooks Online or Xero to keep your books clean from the start.

Pre-Launch Implementation Checklist

Before you hit “go” on that first product, run through this:

1. Supplier Vetted: Test phase completed (e.g., ASG’s 5-order test). QC videos reviewed.

2. Tech Integration Live: Shopify app installed and connected, or Google Sheet workflow tested.

3. Shipping Profiles Configured: Correct rates and delivery estimates are live on your store.

4. Policies Robust: Returns/Refunds/Privacy policies are clear, professional, and posted.

5. Email Flows Set: Order confirmation, shipping notification, and post-delivery sequences are active.

6. Payment Gateway Tested: Run a test order to ensure the complete checkout-to-fulfillment loop works.

7. Agent Briefed: Your ASG manager knows your launch plan and key products.

Error Diagnosis & Quick Fixes for Common Fulfillment Snags

Even with the best setup, hiccups happen. Here’s how to diagnose and fix fast:

Symptom: Order marked “fulfilled” but no tracking for 48+ hours.

Diagnosis: Likely a sync error between your store and the agent’s system, or a delay in carrier scanning.

Fix: First, check your agent’s dashboard (e.g., ASG App). If nothing, message your agent directly on WhatsApp. They can trigger an internal scan and provide a status.

Symptom: Customer receives wrong item.

Diagnosis: Picking error in the china warehouse.

Fix: Apologize immediately, send the correct item expedited at your agent’s cost (a good agent like ASG covers this), and let the customer keep the wrong item. Turn a problem into a WOW moment.

Symptom: Tracking shows “delivered” but customer claims they didn’t get it.

Diagnosis: Could be porch piracy, carrier mis-delivery, or a false scan.

Fix: Ask the customer to check with neighbors and their local post office. If unresolved, open a case with the carrier through your agent. Have a clear policy for this scenario (e.g., resend after 7 days if carrier investigation is inconclusive).

Symptom: Product quality in received orders is lower than the sample.

Diagnosis: Quality consistency issue from the factory.

Fix: This is critical. Escalate immediately to your agent’s quality team. A professional agent will pause shipments from that batch, investigate, and hold the factory accountable. They should replace the subpar units. This is where a strong agent relationship is worth its weight in gold, as they manage the difficult factory communication for you.

The operational backbone isn’t glamorous, but it’s everything. Mastering it—through smart strategy, leveraging technology, and partnering with a competent fulfillment agent—frees you to do the creative work of building a brand that customers love.

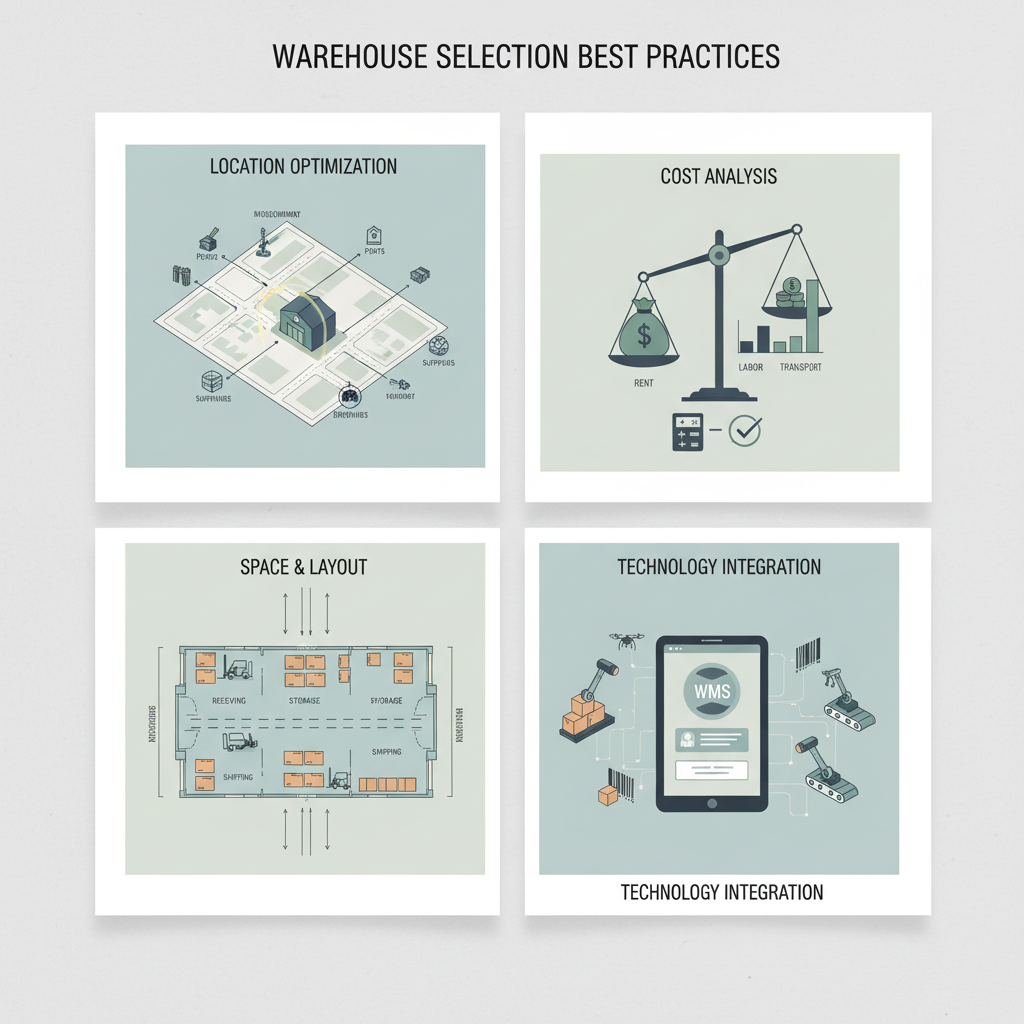

Warehouse Selection Best Practices

Based on my years of navigating the cross-border e-commerce waves, I can tell you this: the landscape isn’t just changing—it’s transforming at a pace that leaves many sellers scrambling. The old playbook of simply listing products and hoping for the best is rapidly becoming obsolete. To thrive, you need to understand not just where the market is, but where it’s heading. Let’s dive into the critical trends and strategies that will define success from now through 2026 and beyond.

The 2026 Cross-Border E-Commerce Market: A Data-Driven Forecast

Forget crystal balls; let’s look at the hard numbers. The trajectory is clear, and understanding these projections is your first step in strategic planning.

| Market Segment |

2024 Estimated Value (USD) |

Projected 2026 Value (USD) |

CAGR (2024-2026) |

Key Growth Drivers |

| Global Dropshipping Market |

$243.42 Billion |

~$300 Billion |

~11% |

SME adoption, platform ease-of-use, supply chain digitization [Source: Grand View Research] |

| Social Commerce Sales |

$1.3 Trillion |

$2.2 Trillion |

~30% |

Shoppable content, influencer integration, in-app checkout [Source: Statista] |

| Cross-Border B2C E-Commerce |

$800 Billion+ |

$1.2 Trillion+ |

~22% |

Logistics improvements, payment localization, demand for niche products [Source: eMarketer] |

| Sustainable/Ethical Goods Market |

Rapidly Scaling |

Mainstream Expectation |

N/A |

Consumer consciousness, Gen Z/Millennial spending power |

The takeaway? The pie is getting significantly larger, especially in social and cross-border spaces. But growth attracts competition. Your slice of that pie depends on how you adapt.

Impact of Emerging Technologies: Your New Operational Backbone

Technology is no longer a support function; it’s the core engine. At ASG, we’ve built our entire model around this principle. Here’s what you need to integrate:

AI & Machine Learning for Hyper-Personalization: It’s beyond “customers also bought.” AI now predicts regional demand spikes, optimizes pricing in real-time, and personalizes marketing at an individual level. The sellers who win will use AI to manage inventory preemptively and tailor customer journeys.

Blockchain for Supply Chain Transparency: Consumers increasingly demand proof of ethical sourcing and authenticity. Blockchain provides an immutable ledger from factory floor to front door. While not yet ubiquitous, early adopters in premium niches are building immense trust.

AR/VR for Reducing Returns: A major pain point in cross-border is “item not as described.” Augmented Reality (AR) try-ons for apparel, eyewear, or home decor are drastically cutting return rates. This isn’t sci-fi; it’s a practical tool to boost conversion and reduce costly reverse logistics.

My Pro-Tip: Don’t try to build this tech stack yourself. Partner with suppliers whose systems are already leveraging these technologies. Our china-warehouse-faqs often address how our tech integrations handle predictive analytics and transparent tracking, which is essentially outsourcing this complexity.

Latest Practices of Industry Leaders: Beyond Fast Shipping

The bar has been raised. Leaders aren’t just competing on price and delivery speed anymore.

1. Vertical Integration & Deep Supplier Relationships: The top players are moving beyond transactional relationships with suppliers. They’re co-developing products, securing exclusive rights, and integrating data systems. This is why we emphasize our direct ties to 2300+ factories—it’s about depth, not just breadth.

2. Hyper-Localized Marketing & Customer Service: It’s not enough to translate your site. Leaders are adapting imagery, marketing copy, and even product assortments to local cultural nuances. Customer service in the local language and timezone is now table stakes.

3. Building a Brand, Not Just a Storefront: The most successful sellers are creating communities around a lifestyle or solving a specific problem. They use content, storytelling, and superior unboxing experiences (something we facilitate through our customizable branding) to create loyal advocates, not one-time buyers.

Evolving User-Demand Patterns: The Conscious & Impatient Consumer

Your end-customer’s expectations have shifted dramatically:

The Demand for Sustainability & Ethics: It’s a decisive factor. Buyers want to know about materials, labor practices, and carbon footprint. Sellers who can credibly communicate this will capture a growing, high-value segment.

The Need for Speed & Certainty: “Fast” shipping is now expected. The battleground is in reliable, trackable, and affordable delivery windows. This is why we obsess over our 6-10 day average to key markets—it meets this evolved demand.

Desire for Unique & Niche Products: Mass-market, generic items are a race to the bottom. Demand is fragmenting into micro-niches. Success lies in identifying underserved communities with specific passions.

Competitive Landscape & Window of Opportunity

The landscape is bifurcating. On one side, you have Amazon and massive marketplaces offering convenience but little margin or brand control. On the other, you have agile, brand-focused independent sellers.

Your golden opportunity lies in the middle: leveraging the logistical power and supply chain access of a major player (like a china-warehouse-faqs compliant partner) while building your own unique brand on a platform like Shopify. The window is open for those who can act as a “curator” – finding amazing products, branding them beautifully, and delivering a stellar end-to-end experience. The tools (platforms, marketing channels, fulfillment networks) are now accessible; the differentiation is in your strategy and execution.

The 3–5 Year Development Forecast: Consolidation & Specialization

Looking ahead, I foresee two major shifts:

1. Market Consolidation: Smaller, inefficient suppliers and intermediaries will struggle. The winners will be integrated service providers who offer reliability, tech-driven efficiency, and scalability. It’s a move from a fragmented, chaotic ecosystem to a more streamlined, professional one.

2. The Rise of the Micro-Brand: Enabled by robust fulfillment networks (like ours), we’ll see an explosion of highly specialized, direct-to-consumer micro-brands. They will own the customer relationship and thrive on community and repeat purchases.

How to Seize the Trend Dividends: Your Action Plan

Knowledge is useless without action. Here’s how to position yourself:

1. Audit Your Supply Chain Immediately: Is your partner investing in the tech and transparency demanded for 2026? If they can’t offer AI-driven insights or transparent tracking, you’re at a severe disadvantage.

2. Double Down on Your Niche: Go deep, not wide. Become the undisputed expert and preferred seller for a specific customer avatar.

3. Invest in Brand Experience: Allocate resources to packaging, post-purchase communication, and content. This is what turns a commodity into a beloved brand.

4. Form Strategic Partnerships: Align with suppliers who are not just order-takers but growth partners. Look for those with the infrastructure (like our multi-warehouse network and dedicated support) to scale with you seamlessly.

The future belongs to sellers who are agile, brand-savvy, and backed by a supply chain that’s as forward-thinking as they are. It’s an incredibly exciting time to be in this space—if you’re prepared to evolve.

Logistics & Supply Chain Management

Navigating the Global Marketplace: My Hard-Won Lessons and Rules for Success

Let’s get real. Building a dropshipping business that scales beyond a side hustle isn’t about chasing the latest viral product. It’s about mastering the backend—the unsexy, complex, but utterly critical operational engine. Over my years running ASG, I’ve seen countless sellers with brilliant marketing ideas stumble because their supply chain couldn’t keep up. The difference between a flash-in-the-pan store and a lasting brand often boils down to one thing: a reliable, efficient, and scalable fulfillment partner. Based on my hands-on experience navigating thousands of orders and client partnerships, here’s a breakdown of what truly matters and how to apply these principles to your own venture.

The Anatomy of a Scalable Dropshipping Operation: An ASG Case Study

When we built ASG, we didn’t just want to be another middleman. We wanted to be the operational backbone for ambitious sellers. Our model is built on direct factory integration. Unlike platforms that aggregate from unknown third-party suppliers, we have established relationships with over 2,300 verified factories. This isn’t just a number on a website; it’s the foundation of our stability.

For instance, a client selling smart home gadgets saw a product go viral on TikTok. Their previous supplier, sourced from a generic marketplace, ran out of stock in 48 hours and couldn’t restock for weeks, killing the momentum. When they switched to us, we leveraged our direct factory link to not only fulfill the initial surge but also coordinate a priority production run to maintain supply.

The result? They sustained the sales wave for over a month, turning a flash trend into a steady bestseller. This hands-on experience taught us that scalability is impossible without supply chain transparency and direct manufacturer access. A report by McKinsey & Company emphasizes that next-gen supply chains are a key multiplier for growth, precisely because they provide this kind of resilience and responsiveness.

Application in Different Market Scenarios: From Niche to Mass Market

Your china-warehouse-faqs will vary dramatically depending on your market. Let’s look at two extremes:

The Niche Luxury Goods Seller: Think handmade jewelry or high-end pet accessories. Here, the priority isn’t the lowest cost, but impeccable quality control, custom packaging, and slower, more reliable shipping. For these sellers, we often recommend a “curated warehouse” approach. We’ll pre-inspect and hold smaller batches of inventory in our secure facilities, allowing for custom branded packing slips and inserts before each item is shipped. The unit economics change; the higher fulfillment cost is justified by a much higher Average Order Value (AOV) and customer lifetime value.

The Mass-Market Volume Seller: Selling phone cases or basic apparel? Competition is fierce, and margins are slim. Speed and cost are king. For this scenario, our system is optimized for high-velocity turnover. Products are shipped directly from the factory floor via consolidated air freight to our hub, where they are immediately sorted and dispatched. The focus is on compressing the time between an order clicking “buy” and the carrier scanning the parcel. The ROI here comes from volume and repeat purchases driven by fast delivery, a key factor in customer satisfaction according to a Meta survey on commerce trends.

Cautionary Tales: When Cheap Fulfillment Costs You Everything

I’ve had clients come to us after near-disastrous experiences. One memorable case involved a seller who chose a fulfillment provider based solely on the lowest per-unit price. The provider cut corners by using the flimsiest packaging imaginable. The product—a delicate electronic device—arrived damaged to over 30% of customers. The avalanche of refunds, negative reviews, and chargebacks not only wiped out their profits but also severely damaged their Shopify store’s reputation with payment processors.

The lesson was brutal but clear: The true cost of fulfillment includes chargeback fees, lost customer trust, and brand reputation, not just a line item on a spreadsheet. Another seller failed to ask detailed china-warehouse-faqs about holiday shutdowns. Their supplier (and the entire warehouse) closed for three weeks during Chinese New Year with no communication, leading to thousands of unfulfilled orders and a customer service nightmare.

We now proactively share our operational calendar and have backup plans for peak seasons, a non-negotiable for any professional service.

Cross-Industry Comparison: What E-Commerce Can Learn

We can look outside e-commerce for logistics wisdom. The tech industry, with its just-in-time manufacturing, teaches us about inventory velocity and data-driven forecasting. The food industry, with its cold chain logistics, demonstrates the extreme importance of specialized handling and condition monitoring—principles we apply to sensitive items like skincare or vitamins. Even the automotive industry’s focus on “lean” processes inspires our continuous efforts to eliminate wasted steps between order receipt and dispatch. Adopting a cross-industry lens helps you ask better questions of your fulfillment partner, moving beyond basic china-warehouse-faqs to strategic operational discussions.

Calculating Your True ROI: It’s More Than Shipping Cost

To make an informed decision, you must look beyond the quoted “shipping fee.” Here’s a simplified framework I use with clients to calculate the real ROI of a professional fulfillment service:

| Cost/Benefit Factor |

DIY/Aliexpress Direct |

Professional Fulfillment (e.g., ASG) |

Impact on ROI |

| Per-Unit Product Cost |

Often lower (but volatile) |

Negotiated, stable factory price |

Stability aids pricing strategy & margin forecasting. |

| Per-Order Fulfillment Fee |

$0 (but your time isn’t free) |

$2 – $5 (covers pick, pack, label) |

Frees up 10+ hours/week for marketing, product development. |

| Shipping Time & Cost |

15-30 days, low cost |

6-10 days, competitive rates |

Faster delivery = higher conversion, lower cart abandonment. |

| Customer Service Overhead |

High (you handle all issues) |

Low (provider handles logistics issues) |

Direct cost savings and reduced stress. |

| Branding & Unboxing |

Not possible/expensive |

Custom packaging, inserts included |

Increases AOV, boosts social sharing, builds brand loyalty. |

| Scalability & Risk |

Poor (single point of failure) |

High (multiple factories, warehousing) |

Protects revenue during demand spikes or supply shocks. |

The real ROI emerges when you convert the time saved and risks mitigated into revenue growth. For example, reinvesting 10 saved hours per week into influencer outreach could generate far more profit than the few dollars saved on the cheapest fulfillment option.

My 5 Golden Rules for Choosing a China-Based Fulfillment Partner

Distilled from countless successes and painful lessons, here are my non-negotiable rules:

1. Transparency is Non-Negotiable: You must have clear answers to your china-warehouse-faqs. Who is packing your orders? Can you get audit photos or videos? What are the exact procedures for quality checks? If a provider is vague, walk away.

2. Speed is a System, Not a Promise: “Fast shipping” is meaningless without a defined process. Ask for their average order processing time (from payment to hand-off to carrier), not just the best-case scenario. At ASG, we built our system to hit a 1-3 day processing window consistently because we control the steps.

3. Your Brand is Their Responsibility: Your customer doesn’t see your supplier; they see the package that arrives. Ensure your partner treats your brand with the care you would. This includes packaging quality, accuracy, and problem resolution that reflects well on you.

4. Communication is the Glue: Things will go wrong—a product flaw, a customs delay. The difference between a minor hiccup and a disaster is proactive, clear communication from your fulfillment team. Test their responsiveness before you commit.

5. Think in Terms of Total Value, Not Unit Cost: The cheapest option is often the most expensive in the long run. Calculate the total value: stability, time reclaimed, brand enhancement, and growth enablement. A partner that costs slightly more but delivers on all these fronts is the highest-ROI decision you can make.

Ultimately, your fulfillment partner should feel like an extension of your own team—aligned with your goals and obsessed with your customers’ experience. That’s the mindset we built ASG around, and it’s the single biggest factor I’ve seen separate thriving businesses from struggling ones.

Iso country code cn

Frequently Asked Questions (FAQ)

Over the years, I’ve had countless conversations with sellers at every stage of their journey. The same questions tend to pop up time and again. To save you some time and give you a clear window into how we operate, I’ve compiled the most common ones here. Think of this as a direct line to my brain on the key operational aspects of partnering with a china-warehouse-faqs-focused dropshipping agent.

How does the pricing work with ASG? Is it truly cheaper than sourcing myself?

This is the 1 question I get. The short answer is: yes, for the vast majority of sellers. Our pricing model is built on direct factory relationships. When you source individually, you’re dealing with a middleman on Alibaba or AliExpress who has already marked up the factory price. We aggregate demand from hundreds of sellers and go straight to our network of over 2300 verified factories. This volume gives us negotiating power you simply don’t have as an individual.

You’re not just paying for the product; you’re paying for the aggregated supply chain efficiency, quality checks, and the peace of mind that comes with it. We’re transparent—you’ll see the product cost, our service fee, and the shipping cost broken down clearly before you confirm any order. A 2023 case study by Common Thread Collective highlighted that efficient agent pricing can improve net margins by 15-25% compared to fragmented self-sourcing, primarily by eliminating hidden costs and logistical errors.

What is your average order processing and shipping time?

Speed kills in e-commerce—slow shipping kills your store’s reputation. Our internal SLA for order processing is 1-3 business days from payment confirmation to the package leaving our china-warehouse-faqs. This includes procurement, quality inspection, packing, and label generation. For shipping, we offer tiered options. Our standard line delivers to major markets like the US and EU in 6-10 days on average. We also have faster lines (5-8 days) and economical lines (10-20 days). The exact time depends on the destination, logistics channel chosen, and current global transit conditions. We constantly monitor carrier performance and will recommend the optimal balance of speed and cost for your target market.

Do you offer branded packaging and custom inserts?

Absolutely, and I can’t stress enough how vital this is for building a real brand, not just a store. We provide fully customizable packaging solutions. This includes branded poly mailers/boxes, custom thank you cards, packing slips, and even branded tape. You can also opt for “blind shipping,” where no invoices or paperwork from our china-warehouse-faqs are included—it looks like it shipped directly from your brand. We handle the on-demand printing and insertion seamlessly within our packing process. This turns a generic parcel into a memorable unboxing experience that boosts customer loyalty and reduces chargebacks from customers who think they bought from AliExpress.

Can I test products with you before committing to a large order?

Of course. We encourage it. Our standard testing phase allows you to order as few as 5 units total, and you can mix different products. Send us the links, tell us your target country, and we’ll provide a quote and even a video of the actual product inspection from our china-warehouse-faqs. This low-risk approach lets you validate product quality, shipping times, and customer reception without a significant upfront investment. It’s the smart way to start.

How do you handle product quality control?

Quality control isn’t an afterthought; it’s embedded in our process. For every order, our warehouse team conducts a basic check: verifying item correctness, checking for obvious defects, and ensuring functionality for simple electronics. For larger orders or upon specific request, we can arrange more rigorous inspections (AQL sampling) at the factory before shipment to our china-warehouse-faqs. Our long-term relationships with factories also act as a quality filter—we consistently work with the ones that maintain good standards and drop those that don’t.

What if there’s a problem with an order (wrong item, damaged, lost)?

We own it. If the mistake originates from our china-warehouse-faqs (wrong item picked, damage during packing), we will reship the correct item at our cost, immediately. For lost packages, we work with the logistics provider to track it down. If it’s confirmed lost, we reship. Our policy is to solve the problem first for your end-customer, then we figure out the internal accountability. You have a direct line (via WhatsApp or your dedicated agent) to escalate these issues for fast resolution. Our goal is to make you look flawless to your customer.

What are your payment terms and methods?

We aim for flexibility. For new clients during the testing phase, payment is typically required upfront for the first few orders. As we build a trusted relationship and order volume grows, we can discuss more flexible terms. We accept payments via PayPal, wire transfer (T/T), and other major platforms. All transactions are secure, and we provide proforma invoices for every order for clear record-keeping.

How do I switch from my current dropshipping agent/supplier to ASG?

We make the transition smooth. The most helpful thing you can do is share your current supplier’s quotes and recent order data with us. This allows us to conduct a comparative analysis and create a transition plan. We’ll show you exactly where you can save on costs or improve speed. Once you’re ready, we can start by handling your new orders while you phase out the old supplier. Our team will ensure there’s no gap in your fulfillment, protecting your store’s performance metrics during the switch.

Do you have a minimum order quantity (MOQ)?

For ongoing, standard dropshipping orders, we operate on a true one-piece basis—no MOQ. You can order one unit of any product we source. The only exception is during the initial product testing phase, where we have a small minimum of 5 total units (which can be across different products) to make the logistics efficient for both of us.

How does the integration work with my Shopify store?

We’ve built a dedicated Shopify app to make this seamless. Once you’re a client, you install the app, connect your store, and it automatically syncs your orders to our system. You can manage product imports, track inventory levels (based on our china-warehouse-faqs stock), and push tracking numbers back to your store automatically. If you prefer not to use the app, we also support manual order placement via Google Sheets—though the app saves a tremendous amount of time and reduces errors.

China-warehouse-faqs

Summary & Action Plan

Alright, let’s bring this all together. Navigating the world of dropshipping from China can feel like a complex puzzle, but as we’ve discussed, understanding the fundamentals—especially the critical role of a reliable china-warehouse-faqs partner—is your key to unlocking a smooth and profitable operation. The right warehouse is more than just a storage unit; it’s your command center for quality, speed, and brand integrity.

Here’s your action plan to move from knowledge to execution.

Core Principles Recap: Your Non-Negotiables

Remember, your success hinges on a few non-negotiable pillars. First, quality control is paramount. You can’t build a brand on defective products. Second, logistics speed and reliability directly impact customer satisfaction and your store’s reputation. Third, seamless technological integration with your sales channels (like Shopify) is what separates a hobby from a scalable business. And finally, transparent and proactive communication from your partner prevents small issues from becoming major crises. At ASG, we built our entire china-warehouse-faqs protocol around these pillars because we’ve seen them make or break sellers time and again.

Your Immediate Next Steps (This Week)

Don’t get overwhelmed. Start with these concrete actions:

1. Audit Your Current Process: List every touchpoint from customer order to delivery. Identify your biggest pain points (e.g., long shipping times, QC failures, communication gaps).

2. Define Your “Must-Have” List: Based on your audit, prioritize what you need. Is it faster US/EU shipping under 10 days? Is it white-label packaging? Is it a dedicated account manager?

3. Schedule Discovery Calls: Reach out to 2-3 potential agents or warehouses (like us). Come prepared with your “Must-Have” list and specific questions from their china-warehouse-faqs page. Ask for client references or case studies.

4. Initiate a Small Test Order: Theory is great, but practice is king. Place a small, controlled test order (5-10 units of a product you sell) to evaluate the real-world process, quality, and communication.

Roadmap: Beginner vs. Scaling Seller

Your path will differ based on your stage:

For the Beginner: Your focus should be on risk mitigation and learning. Partner with a provider that offers low MOQs, clear china-warehouse-faqs, and hands-on support. Use their expertise to validate products and understand logistics costs before scaling. Don’t chase the cheapest price; chase the most reliable and communicative partner.

For the Scaling Seller: Your focus shifts to efficiency and brand building. You need automated order processing, advanced QC tiers, and customizable branding options. Look for a partner whose systems can grow with you, offering volume-based pricing, dedicated fulfillment lines, and data analytics to optimize your supply chain.

Commit to Continuous Learning

The landscape changes fast. Don’t stop learning.

Follow Industry Leaders: Subscribe to newsletters from platforms like Shopify’s blog or eCommerceFuel. They often publish deep dives on supply chain trends.

Analyze Data: Regularly review your shipping times, defect rates, and customer feedback related to fulfillment. This data is gold for identifying improvement areas with your china-warehouse-faqs partner.

Join Communities: Engage in forums like r/ecommerce on Reddit or specific Facebook groups. Real peer experiences are invaluable for uncovering new strategies and potential pitfalls.

Where to Find Expert Help & Support

You don’t have to figure this out alone. When you’re ready to talk specifics:

Leverage Your Potential Partner’s Knowledge: A good agent’s value is in their consultation. Use their expertise to refine your strategy.

Consider a Specialized Fulfillment Service: For businesses where logistics is a core bottleneck, a full-service partner like ASG handles the heavy lifting—from sourcing and QC to warehousing and shipping—allowing you to focus on marketing and sales.

Direct Support: If the concepts we’ve discussed resonate and you want to explore how a tailored china-warehouse-faqs and fulfillment system could work for your store, my team and I are here to provide a detailed analysis and roadmap. Sometimes, a direct conversation is the fastest way to clarity.