Not sure where to begin with your own product line? The ASG Dropshipping agent will help you find great private label suppliers and handle fulfillment, so you can focus on building your brand from day one. No need to worry about storage or bulk purchases—just start small and grow with confidence.

As your brand picks up momentum, managing inventory and launching new products becomes more complex. Dropshipping gives you the flexibility to expand without tying up capital in stock. It’s a smart way to test ideas while keeping operations lean.

In a niche market, timing and adaptability are everything. Dropshipping allows you to react quickly—release limited editions, test seasonal trends, or cater to specific audiences—without the risk of overproduction or dead stock.

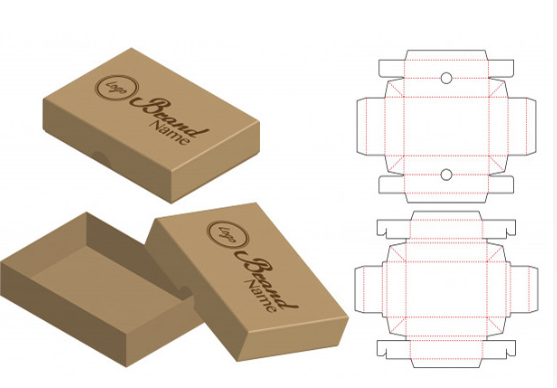

Enhance your brand’s identity with fully customizable packaging options. From logo stickers to custom inserts and color-matched boxes, we help you create a consistent unboxing experience that resonates with your customers. With no need for bulk purchases, each item is packed on demand, giving you the freedom to update designs anytime without storage concerns or production delays.

Turn every order into a memorable moment with personalized gift box packaging. Offer customers add-on features like handwritten notes, holiday themes, or custom wrapping without handling logistics yourself. We handle fulfillment directly, making it easy for you to deliver emotional value with every shipment—boosting brand loyalty and repeat orders.

Collaborating directly with factories gives you more control over packaging quality and customization—but it also requires experience in cross-border communication. We simplify this process for you. By bridging the gap between your brand and the manufacturer, we ensure smooth operations, clear expectations, and reliable delivery timelines from day one.

Finding the right factory on your own can be costly, time-consuming, and filled with uncertainty. We connect you directly to reliable manufacturing sources through our supply network—factories we’ve already verified for quality and performance. You get streamlined access to private label suppliers, optimized production routes, and more predictable costs. This efficiency helps lower your overall product cost structure and improves your margins—without the hidden risks of going it alone.

You want a brand that reflects your identity. We help make that happen by working closely with factories that support detailed customizations—custom packaging, labels, inserts, and even materials. Instead of managing endless communication threads and production revisions, we coordinate everything on your behalf, ensuring your requirements are met with precision and speed.

Through long-term cooperation with trusted factories, we ensure consistent output and quality from every batch. From pre-production samples to final shipment checks, we follow structured processes to maintain high product standards. You don’t have to chase factories or worry about inconsistent quality—we manage that for you, so you can focus on growing your brand with confidence.

Time is often the biggest cost in product development. Our integrated process cuts through the usual delays of factory sourcing, negotiation, and setup. With direct communication channels and priority coordination in place, we help bring your products to market faster—so you can react to trends, test new ideas, and meet customer demand without unnecessary wait times.

WhatsApp us

Start Your Dropshipping Business